Ultrathin luminous ceiling

A ceiling and ultra-thin technology, applied in the direction of optics, light guides, light sources, etc., can solve the problems of thick luminous ceilings and no self-illumination, and achieve the effect of convenient cutting and uniform light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

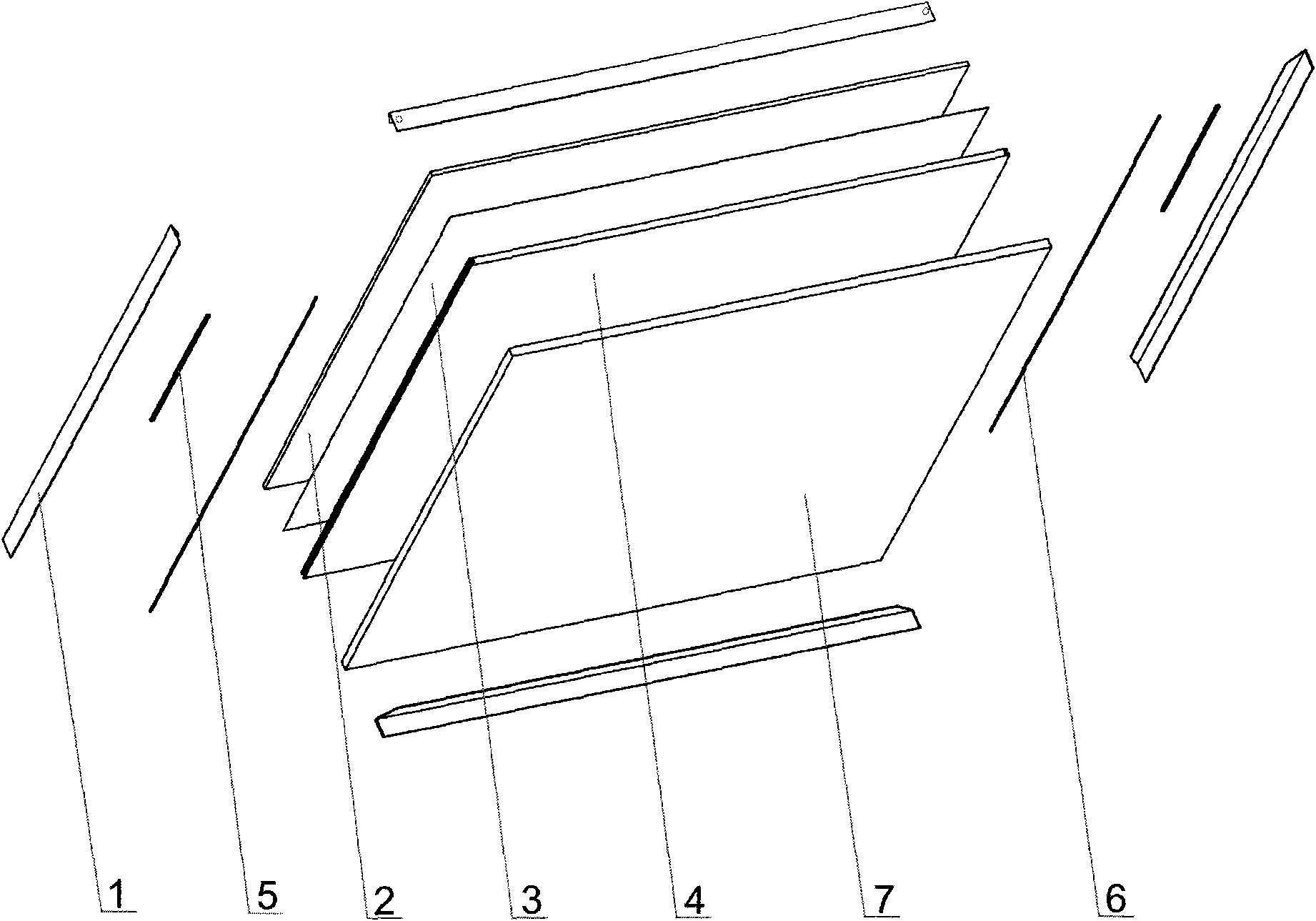

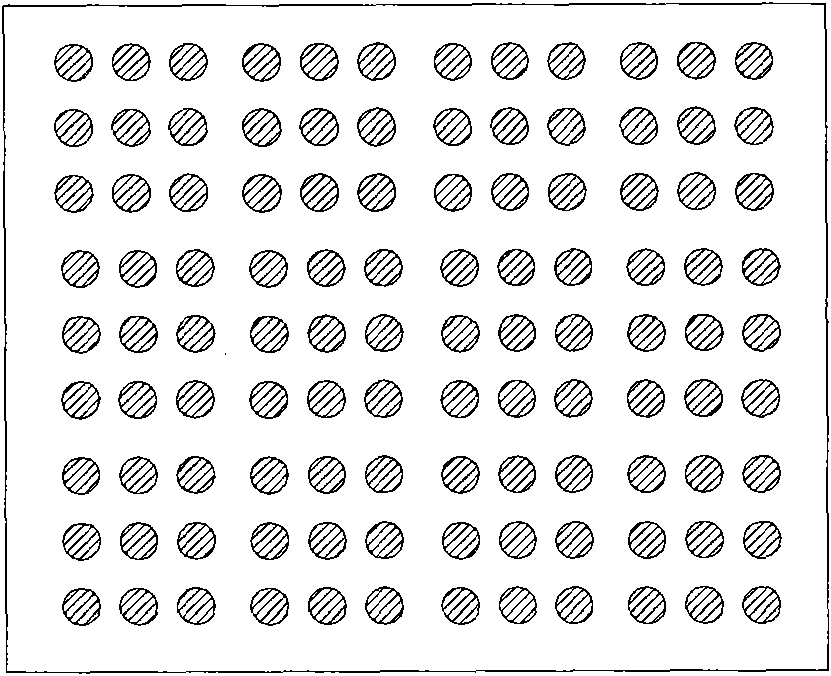

[0019] exist figure 1 Among them, the bottom plate (2), reflective layer (3), light guide plate (4), transparent panel (5), circuit board (5) and light source (6) are assembled together by the outer frame (1), and the light-emitting The circuit board and the light source are placed on the periphery of the light guide plate (4) and assembled together. If a CCFL lamp is used to drive, the high working voltage is hundreds to thousands of volts, and an inverter must be provided. A light guide plate (4) is provided between the reflective layer (3) and the transparent panel (5), and the surface of the light guide plate (4) is provided with a transparent layer of printed dots or engraved dots, the mesh of which is 100-200 mesh. Linear bilateral or unilateral light-emitting circuit boards are arranged in the cavity of the frame body on both sides of the light guide plate, the thickness of the light guide plate (4) is 0.3-2 cm, and the overall thickness of the transparent panel (5) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com