Squirrel-cage vertical shaft wind generating set

A wind turbine, vertical axis technology, applied in wind turbine components, wind turbines, wind turbines at right angles to the wind direction, etc. and other issues to achieve the effect of meeting the structural needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

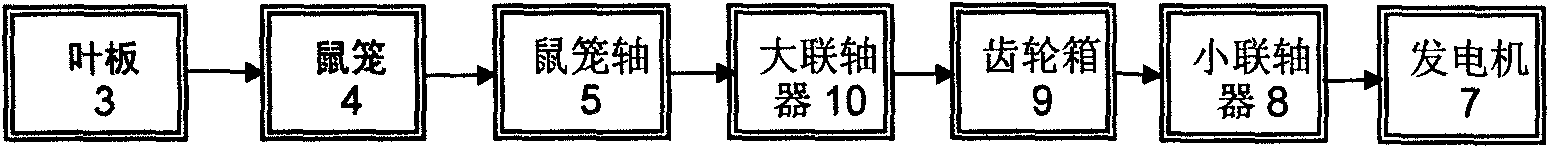

[0019] figure 1 The workflow of a squirrel-cage vertical-axis wind turbine is shown.

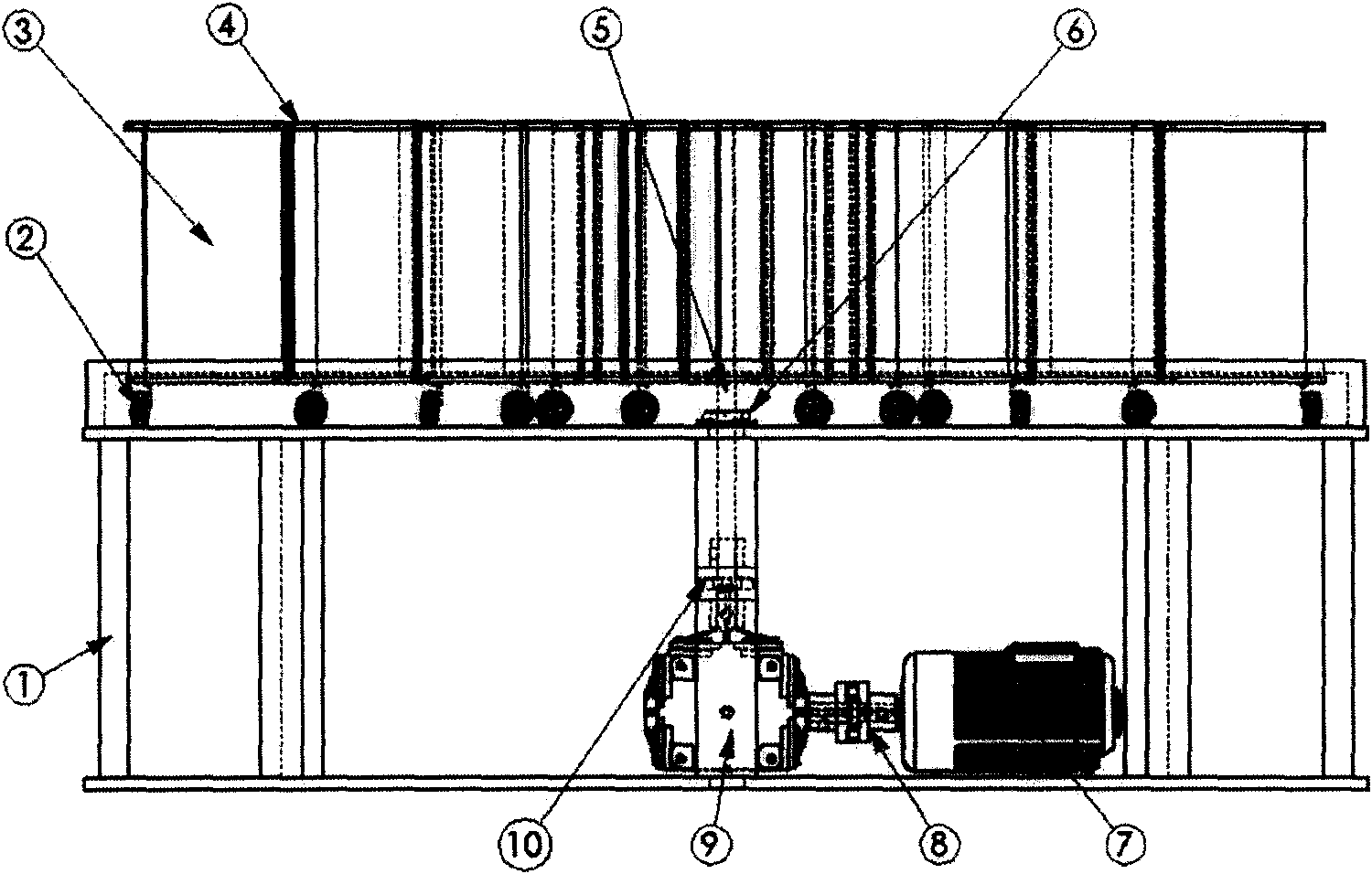

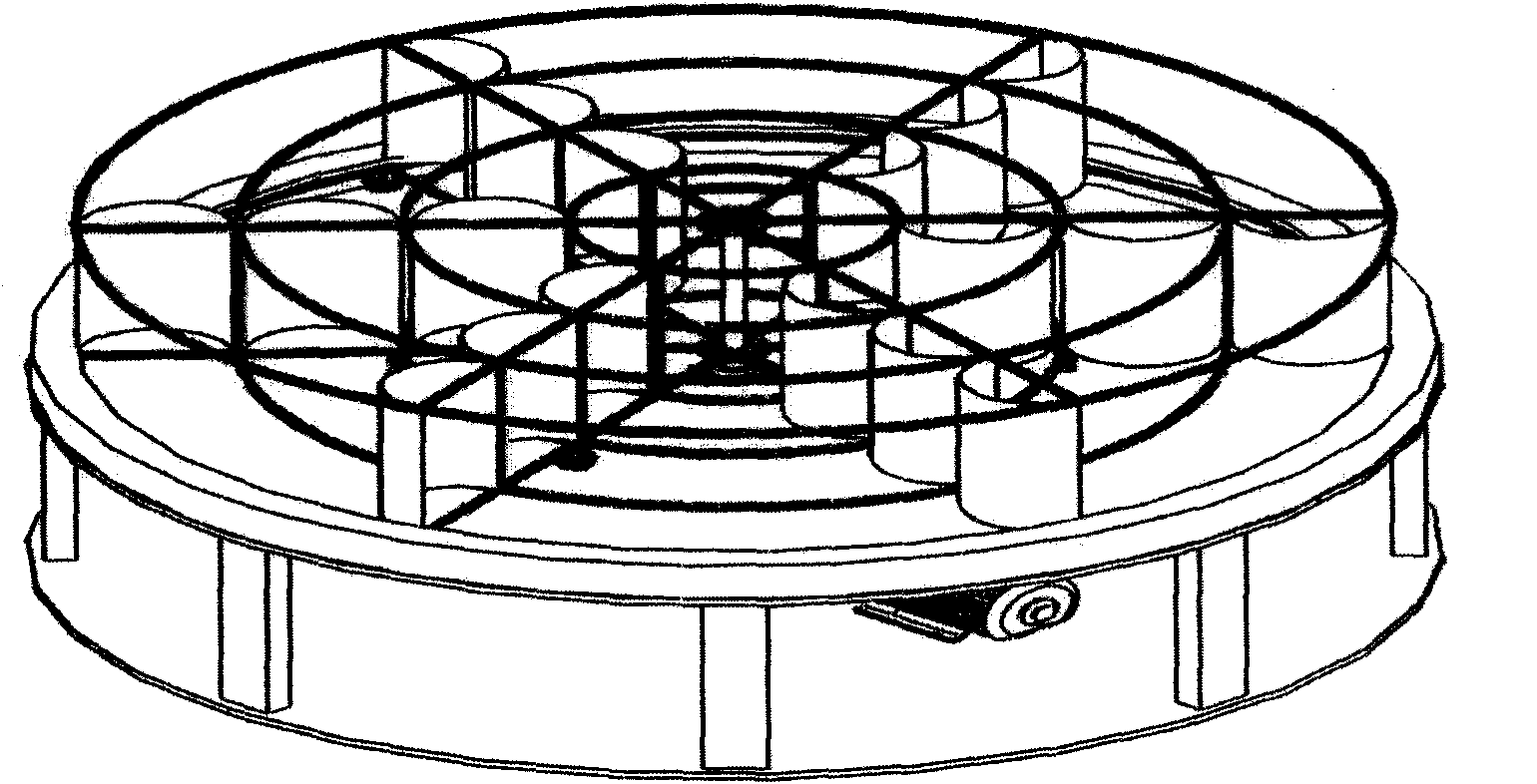

[0020] figure 2 The structure of a squirrel-cage vertical-axis wind turbine is shown.

[0021] The present invention realizes its function through the construction, action and movement of the following equipment.

[0022] Supporting frame (1), all equipment is installed in this structure body, can be arranged in multiple layers. Heavy components (gearbox (9), generator (8) and other equipment) are installed on the bottom of the support frame (1), with a low and stable center of gravity, good wind resistance, and easy equipment installation, daily maintenance, and equipment operation and monitoring. convenient.

[0023] The wheels (2) evenly transfer the overall weight balance of the squirrel cage (4) to the support surface of the support frame (1), and enable th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com