Method for compensating signal of high-precision pressure sensor

A pressure sensor and pressure signal technology, applied in the field of signal processing, can solve the problem of hysteresis error cannot be compensated, and achieve the effect of improving measurement accuracy, compensating error and compensating hysteresis error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

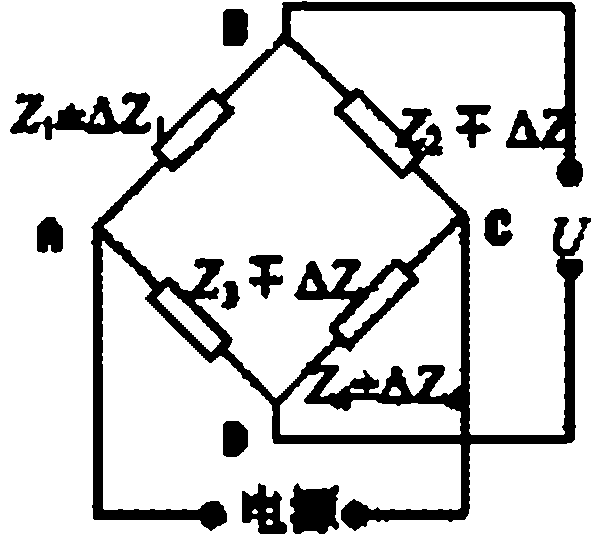

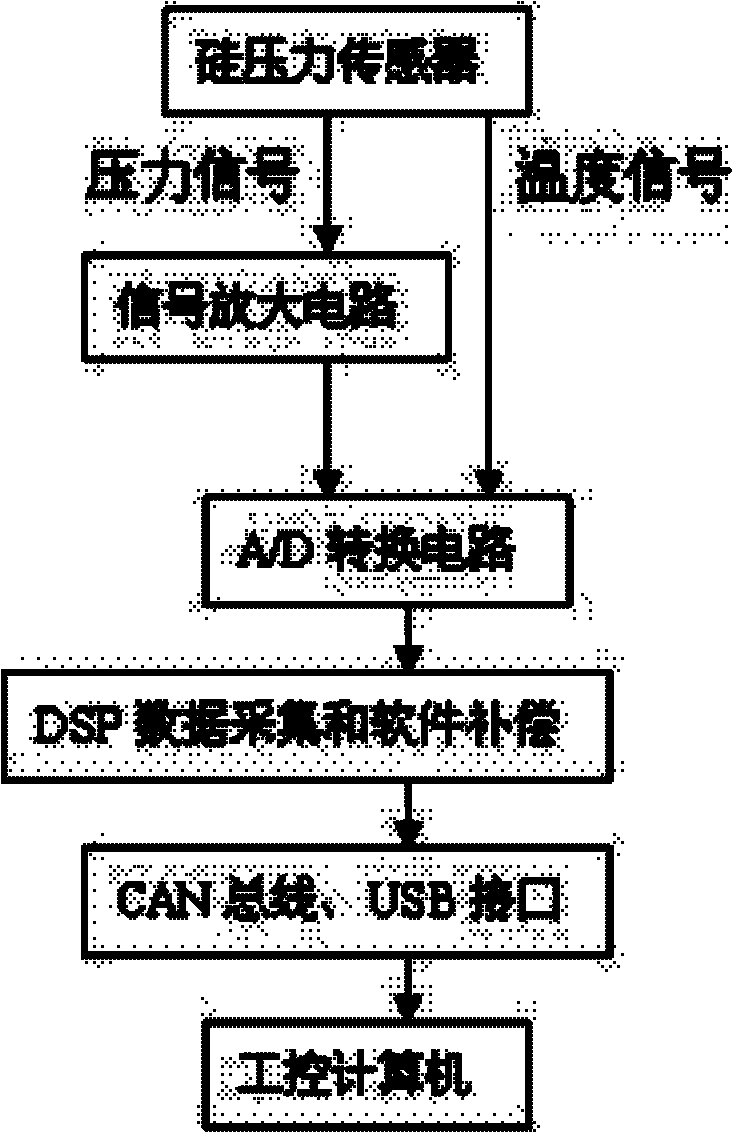

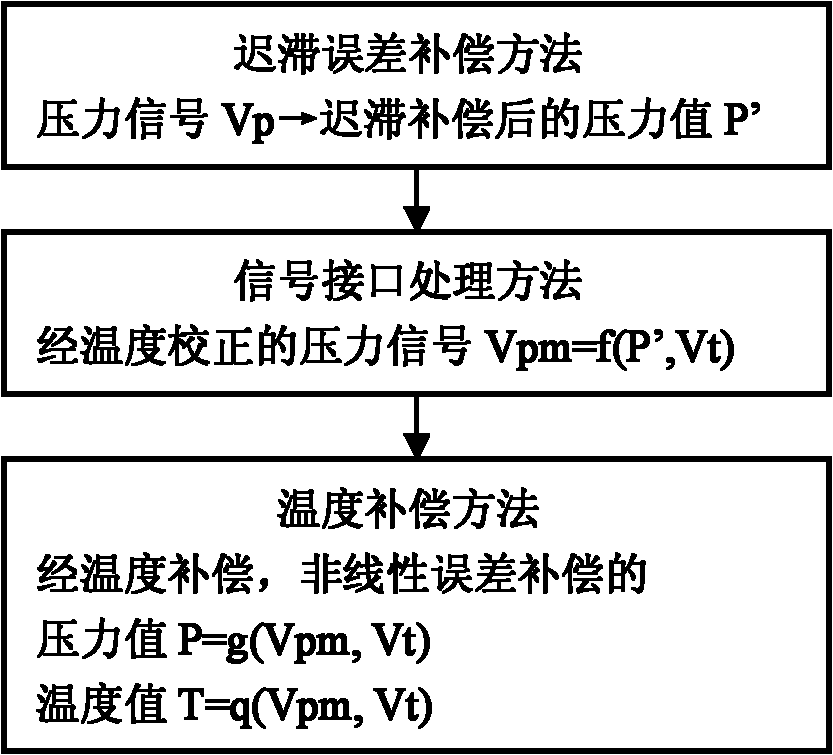

Method used

Image

Examples

Embodiment 1: experiment test effect experiment 。 Embodiment 2

[0106] The following are two examples for testing the high-precision pressure sensor signal compensation method of the present invention. Embodiment 1: The hysteresis error compensation experiment is an experiment conducted to test the effect of hysteresis error compensation under the condition of constant temperature. Embodiment 2: Hysteresis Error Compensation and Temperature Compensation Experiments are conducted under conditions of temperature changes. The experimental instruments mainly include: piston pressure gauge, constant current power supply, temperature control box and high-precision digital multimeter. The measuring range of the silicon pressure sensor used in the embodiment is 0-40Mpa. Under the conditions of room temperature 26°C and humidity 56%RH, the test is carried out with reference to the JB / T 10524-2005 machinery industry standard.

[0107] Example 1: Hysteresis Error Compensation Experiment

[0108] In order to check the hysteresis compensation effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com