Method for dynamically adjusting busbar voltage to improve grid connection efficiency

A bus voltage, dynamic adjustment technology, applied in the direction of single network parallel feeding arrangement, etc., can solve the problems of increasing the bus support capacitor stress, reducing the service life of the capacitor, increasing the stress of the booster circuit components, etc., to improve the efficiency and reliability of the whole machine performance, prolong service life, and reduce device stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

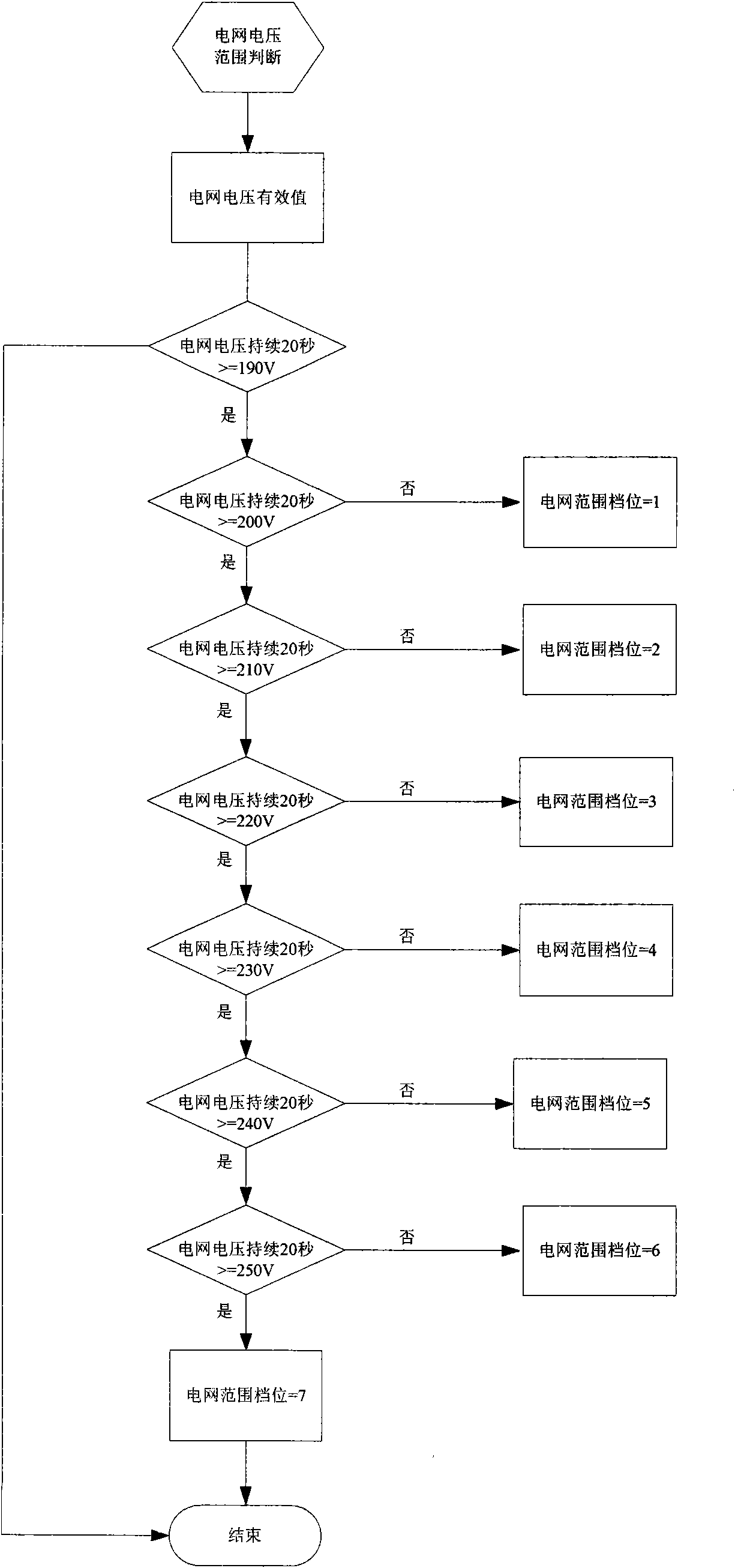

[0024] see figure 1 shown. The minimum and maximum grid voltage has a working range of about 70V. In order not to adjust the bus voltage too frequently, the control system divides the range of 70V into 7 gears, each 10V is a gear. In the first step, the control system first needs to judge the current grid gear. The control system detects the effective value of the grid voltage in real time. When the effective value of the grid voltage is greater than 190V but less than 200V for 20 seconds, the grid gear is considered to be equal to 1. In actual operation, the instantaneous fluctuation of the power grid is very frequent, so when judging the voltage level of the power grid, only when the power grid remains in a certain range for 20 seconds, can it be judged to switch to this level. When the effective value of the grid voltage is greater than 200V but less than 210V and lasts for 20 seconds, the grid gear is considered to be equal to gear 2; when the effective value of the grid...

Embodiment 2

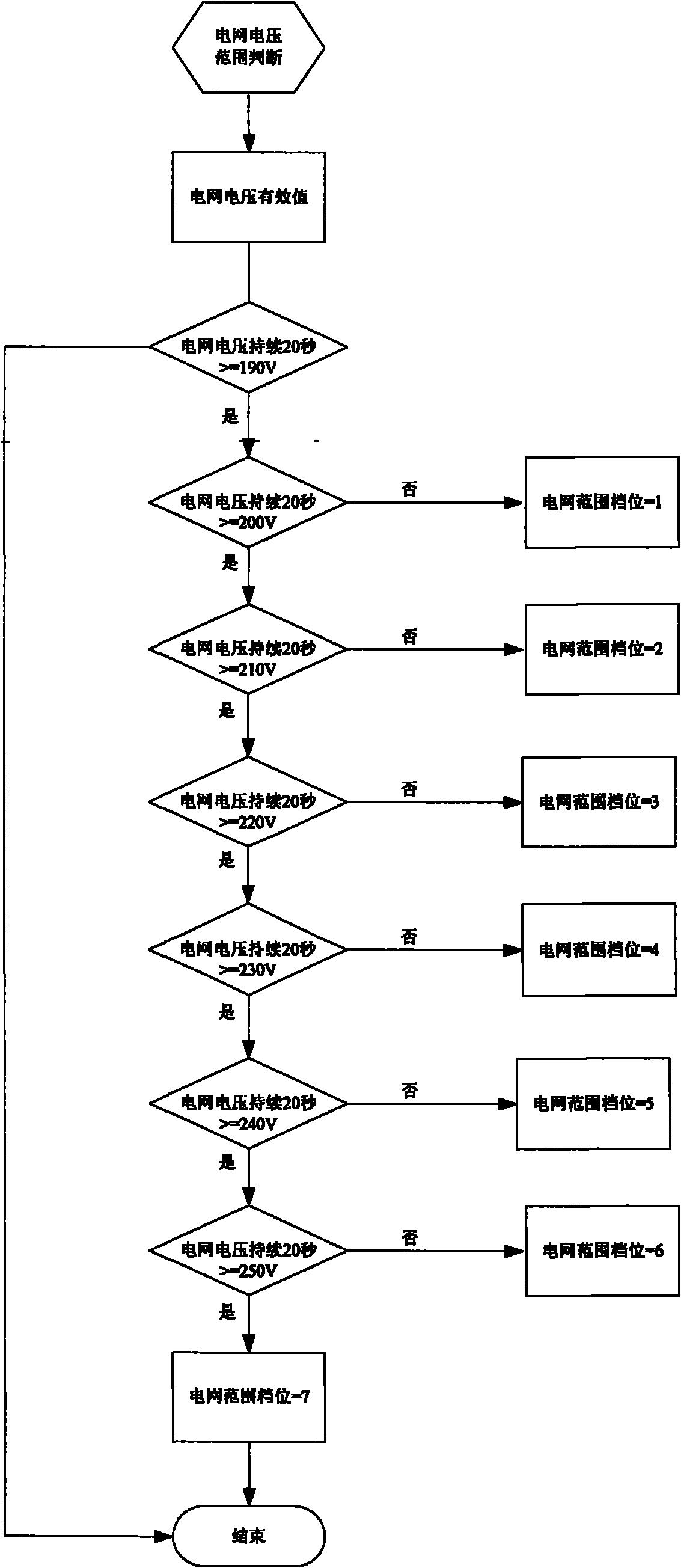

[0026] The minimum and maximum grid voltage has a working range of about 70V. In order not to adjust the bus voltage too frequently, the control system divides the range of 70V into 7 gears, each 10V is a gear. In the first step, the control system first needs to judge the current power grid gear. The control system detects the effective value of the grid voltage in real time. When the effective value of the grid voltage is greater than 190V but less than 200V, it is considered that the power grid gear is equal to gear 1, and other gears Judgments are made in this way. All the other are with embodiment 1.

Embodiment 3

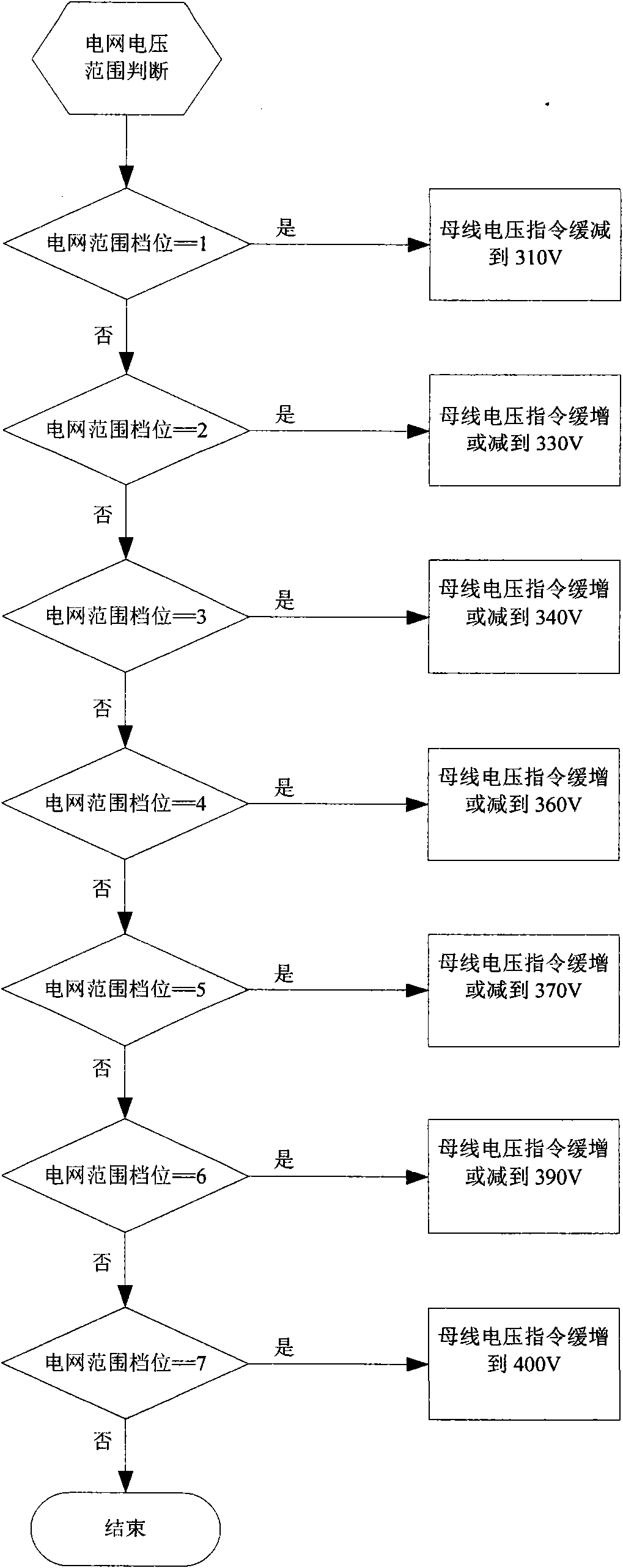

[0028] The minimum and maximum grid voltage has a working range of about 70V. In order not to adjust the bus voltage too frequently, the control system divides the range of 70V into 7 gears, each 10V is a gear. In the first step, the control system first needs to judge the current power grid gear. The control system detects the effective value of the grid voltage in real time. When the effective value of the grid voltage is greater than 190V but less than 200V, it is considered that the power grid gear is equal to gear 1, and other gears Judgments are made in this way. Then determine the size of the bus voltage command according to the gear of the grid voltage, such as figure 2 Shown: when the power grid gear is gear 1, the bus voltage command at this time is not equal to 310V, then it is set to 310V; the rest is the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com