Tobacco stalk expansion method

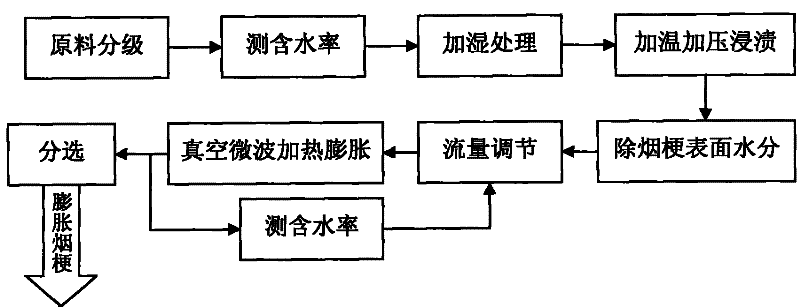

A technology of tobacco stems and expanded tobacco stems, which is applied in the fields of vacuum microwave expansion and water-spraying dipping of tobacco stems, can solve problems such as affecting the usability of expanded tobacco stems and failing to achieve the expansion effect, and achieves easy control of the moisture content of tobacco stems and retention of tobacco flavor. Characteristics, the effect of large expansion volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

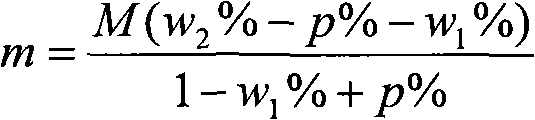

[0045] Taking the tobacco stem production line with a processing flow rate of 20kg / h and a raw material moisture content of 7.38% as an example, the tobacco stems first enter the grading equipment for treatment, and then enter the humidification treatment equipment to spray water evenly, and then flow into the tobacco plant with a temperature of 80°C and a pressure of 0.14MPa. The impregnation equipment is dampened for 15 minutes to make the water content reach 19%. The soaked and dampened tobacco stems are sent to the vacuum microwave expansion chamber with a pressure of 0.01MPa and a temperature of 75°C through an insulated conveyor belt with a temperature of 80°C. For every 1kg of rehydrated tobacco stems, the output power is 4.5kw for rapid heating and expansion of the first microwave cavity, and then for every 1kg of rehydrated tobacco stems, the output power is 2.5kw for medium-speed heating and expansion of the microwave cavity, and finally enters for The output power of...

experiment example 2

[0047] Taking the tobacco stem production line with a processing flow rate of 15kg / h and a raw material moisture content of 10.8% as an example, the tobacco stems first enter the grading equipment for treatment, and then enter the humidification treatment equipment to spray water evenly, and then flow into the tobacco plant with a temperature of 75°C and a pressure of 0.16MPa. Conditions The impregnation equipment is dampened for 10 minutes to make the water content reach 25%. The soaked and dampened tobacco stems are sent to the vacuum microwave expansion chamber with a pressure of 0.02MPa and a temperature of 85°C through an insulated conveyor belt with a temperature of 90°C. For every 1kg of rehydrated tobacco stems, the output power is 5.0kw for heating and expansion in the first microwave cavity, and then for every 1kg of rehydrated tobacco stems, the output power is 2.0kw for medium-speed heating and expansion of the microwave cavity, and finally for each The output power...

Embodiment 3

[0049] Taking the tobacco stem production line with a processing flow rate of 25kg / h and a raw material moisture content of 6.5% as an example, the tobacco stems first enter the grading equipment and then enter the humidification treatment equipment to spray water evenly, and then flow into the tobacco stem at a temperature of 90°C and a pressure of 0.185MPa. The impregnation equipment is dampened for 20 minutes to make the water content reach 15%, and the soaked and dampened tobacco stems are sent to the vacuum microwave expansion chamber with a pressure of 0.005MPa and a temperature of 50°C through an insulated conveyor belt with a temperature of 70°C. After rapid heating and expansion of the first microwave cavity with an output power of 6.0kw for every 1kg of rehydrated tobacco stems, it then enters the medium-speed heating and expansion of a microwave cavity with an output power of 1.5kw for every 1kg of rehydrated tobacco stems, and finally enters For every 1kg of moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com