Ultra-high-strength 9Ni steel for cryogenic environment and preparation process thereof

An ultra-high-strength, preparation technology, applied in temperature control and other directions, can solve the problems of material strength to be improved, high heat treatment temperature, increased energy consumption and production cost, etc., to increase hull transportation capacity, improve welding performance, and reduce hull. The effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

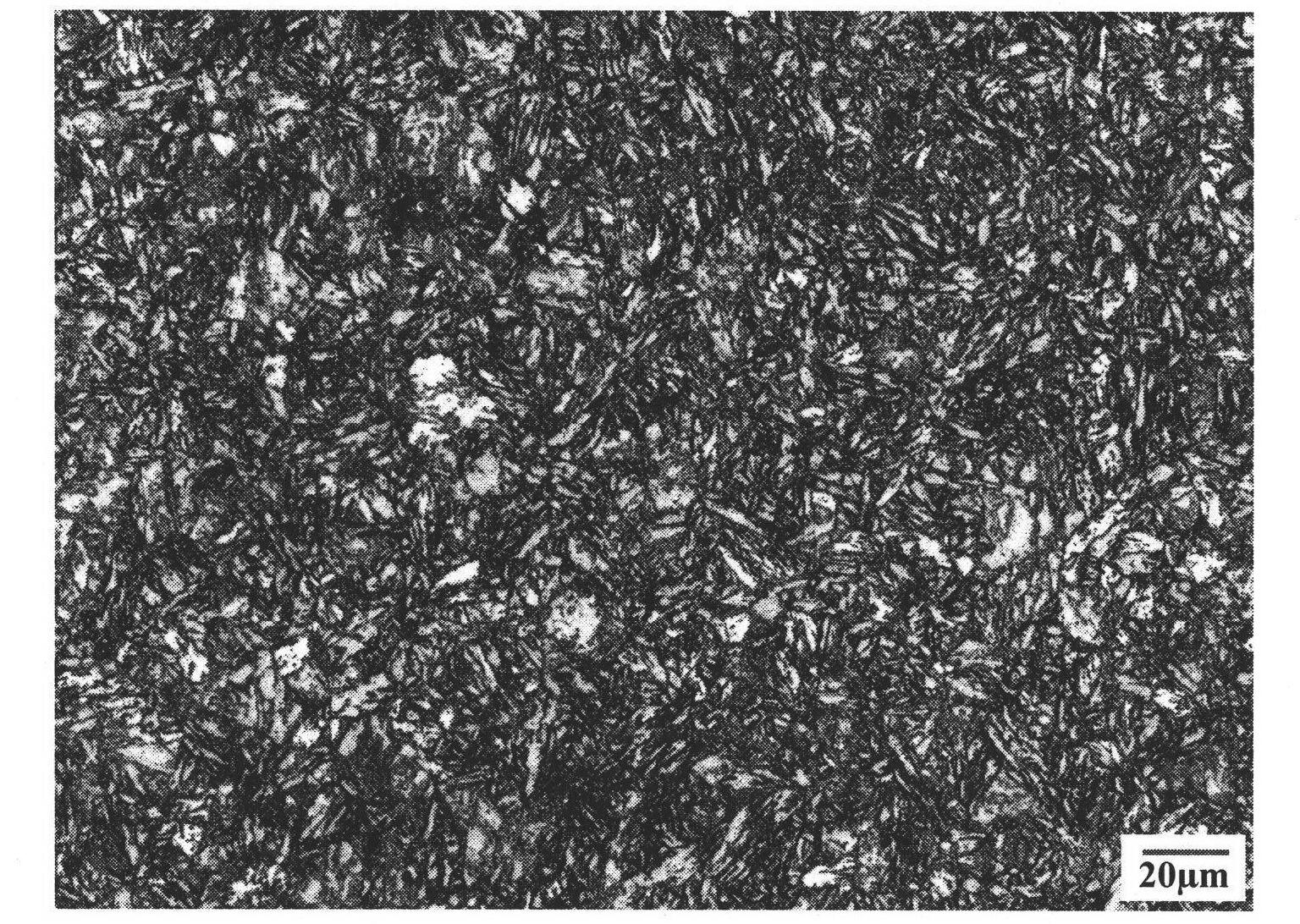

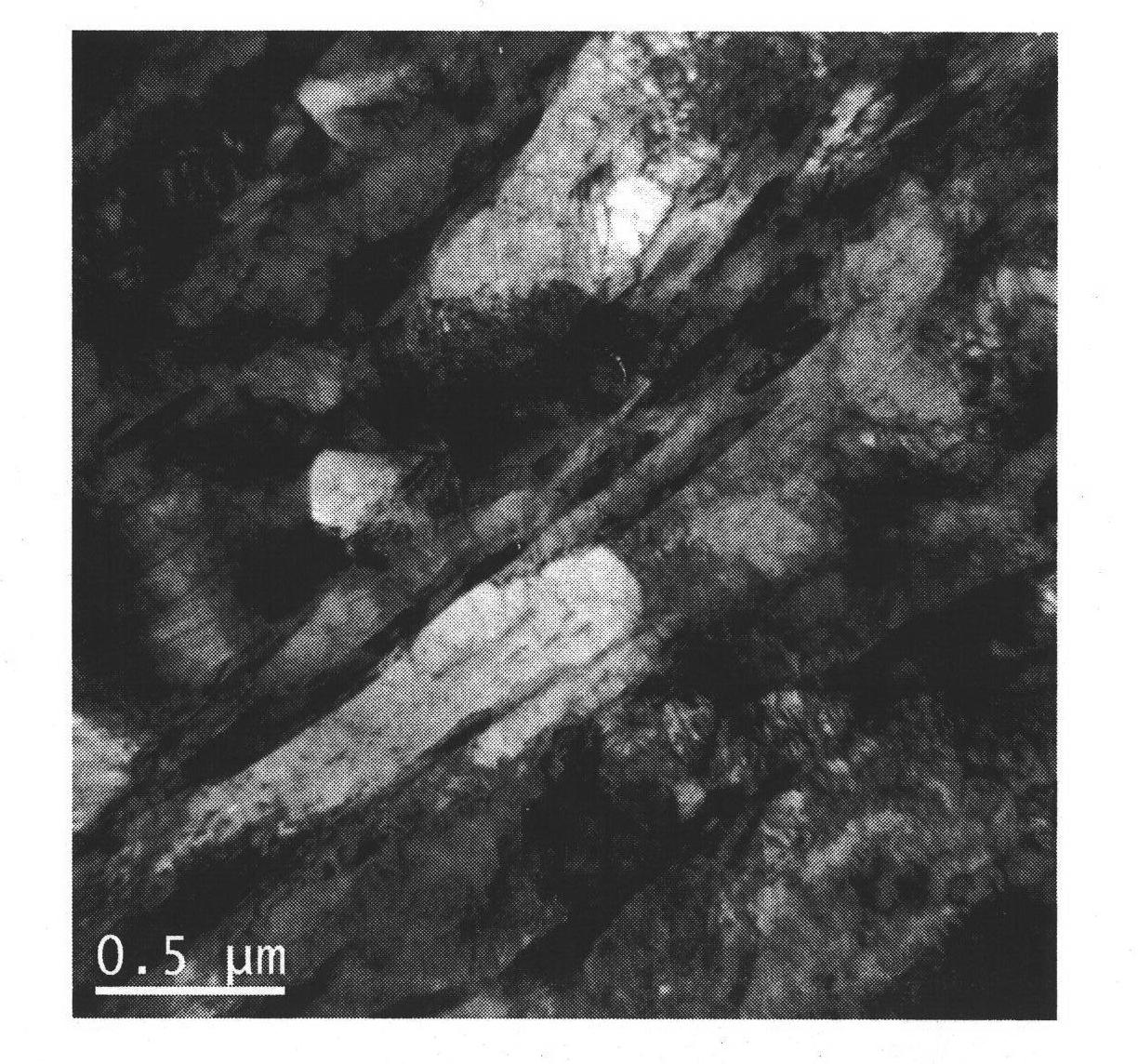

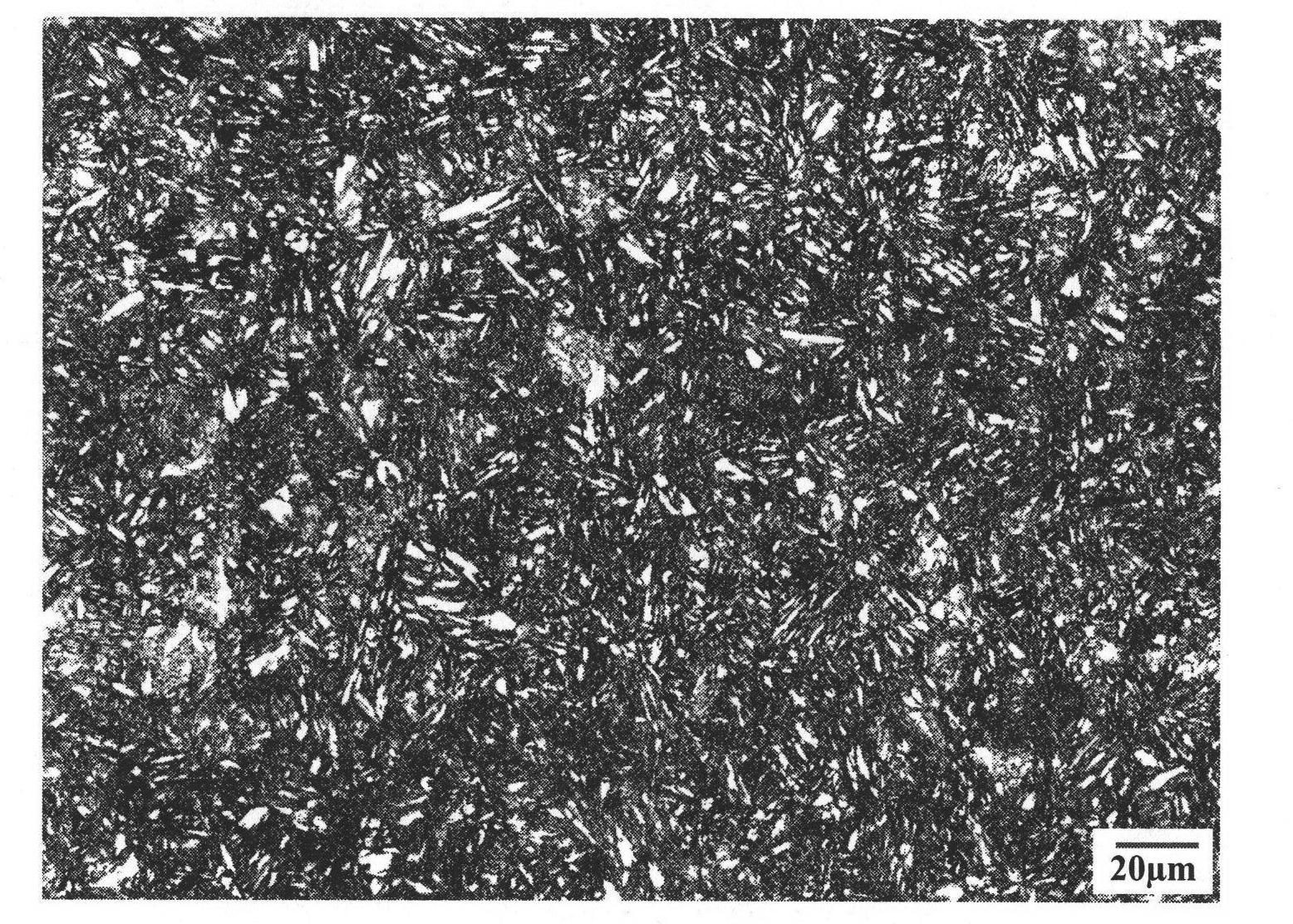

Image

Examples

Embodiment 1

[0049] The ultra-high-strength 9Ni steel used in cryogenic environments contains (wt%): C 0.09%, Si0.07%, Mn 0.34%, P 0.007%, S 0.004%, Ni 9.16%, Cu 1.25%, Al 0.025%, the balance is Fe and unavoidable impurity elements.

[0050] The preparation process of the ultra-high-strength 9Ni steel applied to the cryogenic environment is as follows:

[0051] Prepare smelting raw materials according to the chemical composition of the above-mentioned ultra-high-strength 9Ni steel used in cryogenic environments, and form slabs with a thickness of 110 mm after smelting and casting the smelting raw materials;

[0052] Put the slab into the heating furnace to heat, the heating temperature is 1180°C, and keep it warm for 2 hours;

[0053] After the slab is released from the furnace, two-stage rolling is carried out. The rough rolling start temperature is 1000 ° C, the thickness of the waiting temperature is 61 mm, the finish rolling start temperature is 890 ° C, and the thickness of the rolle...

Embodiment 2

[0057] The chemical composition, rolling and cooling process of the ultra-high-strength 9Ni steel used in cryogenic environments are similar to those in Example 1, but the heat treatment process is quenched at 780°C for 1 hour, quenched at 635°C for 1 hour, and tempered at 570°C for heat preservation. 1h quenching (QLT635°C).

Embodiment 3

[0059] The chemical composition, rolling and cooling process of the ultra-high-strength 9Ni steel used in cryogenic environments are similar to those in Example 1, but the heat treatment process is quenched at 750°C for 1 hour, quenched at 670°C for 1 hour, and tempered at 570°C for 1 hour. (QLT670°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com