Roller type water injection well centering device

A technology for centralizers and water injection wells, applied in drilling equipment, wellbore/well components, measurement, etc., can solve the problems of long axial length of roller centralizers, large contact area of the inner wall of the pipe string, affecting the installation of instruments in the pipe, etc. Achieve the effect of compact structure, easy construction and debugging, and simple parts processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

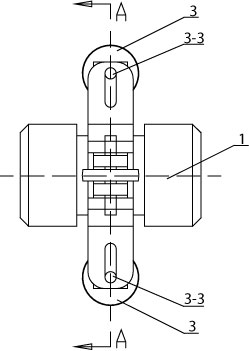

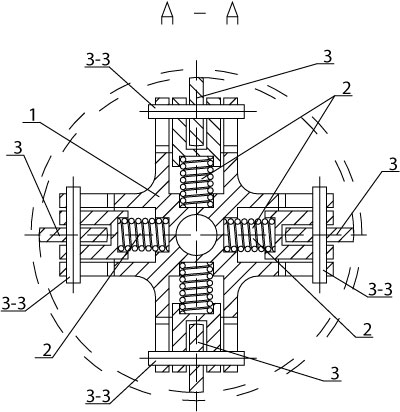

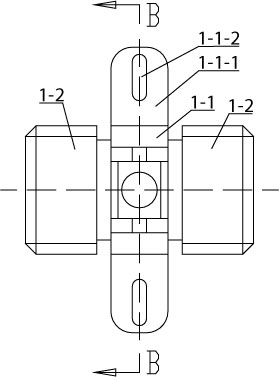

[0007] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment. This embodiment includes a centralizer main body 1, four compression springs 2 and four roller assemblies 3. The centralizer main body 1 is composed of a cross-shaped slide plate 1-1 and two bolt heads 1-2. Two bolt heads The head 1-2 is arranged symmetrically at the center of both sides of the cross-shaped slide plate 1-1, and the cross-shaped slide plate 1-1 is integrated with two bolt heads 1-2, and each bolt head 1-2 on the cross-shaped slide plate 1-1 The outer end surface of the support arm 1-1-1 is provided with a mounting groove 1-1-2, and the mounting groove 1-1-2 divides the support arm 1-1-1 into two side walls 1-1-3, each There is a long hole 1-1-4 on the side wall 1-1-3, and the long holes 1-1-4 on the corresponding two side walls 1-1-3 are the same and facing each other. The installation groove 1-1-4 The bottom surface of 1-2 is provided with first blind hole 1-1-5, ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 5 Describe this embodiment, the junction of the wheel surface and the end surface of the roller 3-1 of this embodiment is a garden arc surface. This design can reduce the contact area between the wheel surface of the roller 3-1 and the inner wall of the water injection well pipeline, thereby reducing friction. When the inner diameter of the pipeline exceeds the maximum diameter of the centralizer for reliable centralization, replace it with a roller with a larger diameter and a matching slider. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Embodiment 3: The material of the roller 3-1 in this embodiment is polytetrafluoroethylene or oil-impregnated nylon. The roller of the existing roller centralizer is rigid, and the contact with the inner wall of the water injection well pipeline is rigid, which requires high precision of the pipeline, and the centralization effect is poor after wear and tear. The roller 3-1 of the present invention adopts the above-mentioned material, so that the roller 3 -1 is in non-rigid contact with the inner wall of the water injection well pipeline, so the roller 3-1 will not damage the inner wall of the water injection well pipeline. Other compositions and connection relations are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com