Full-automatic motor stator iron core manufacture equipment

A technology for motor stators and manufacturing equipment, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low material utilization, high labor intensity, and large material waste, and achieve the goal of improving material utilization, increasing production capacity, and reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

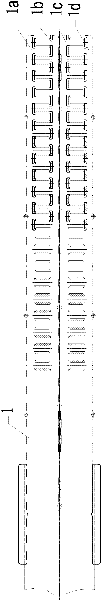

[0017] like figure 1 As shown, the strip 1 used to make the stator core is unfolded and flattened into a straight strip, and the strip 1 is automatically divided into four groove-shaped strips after three-step punching with a high-precision special mold by the strip stamping forming device 1a, 1b, 1c, 1d, the first step is to cut the side of the strip 1 into small squares, the second step is to punch the middle end of the strip into an "I" shape, and the third step is to punch a "C" shape, forming four grooved strips.

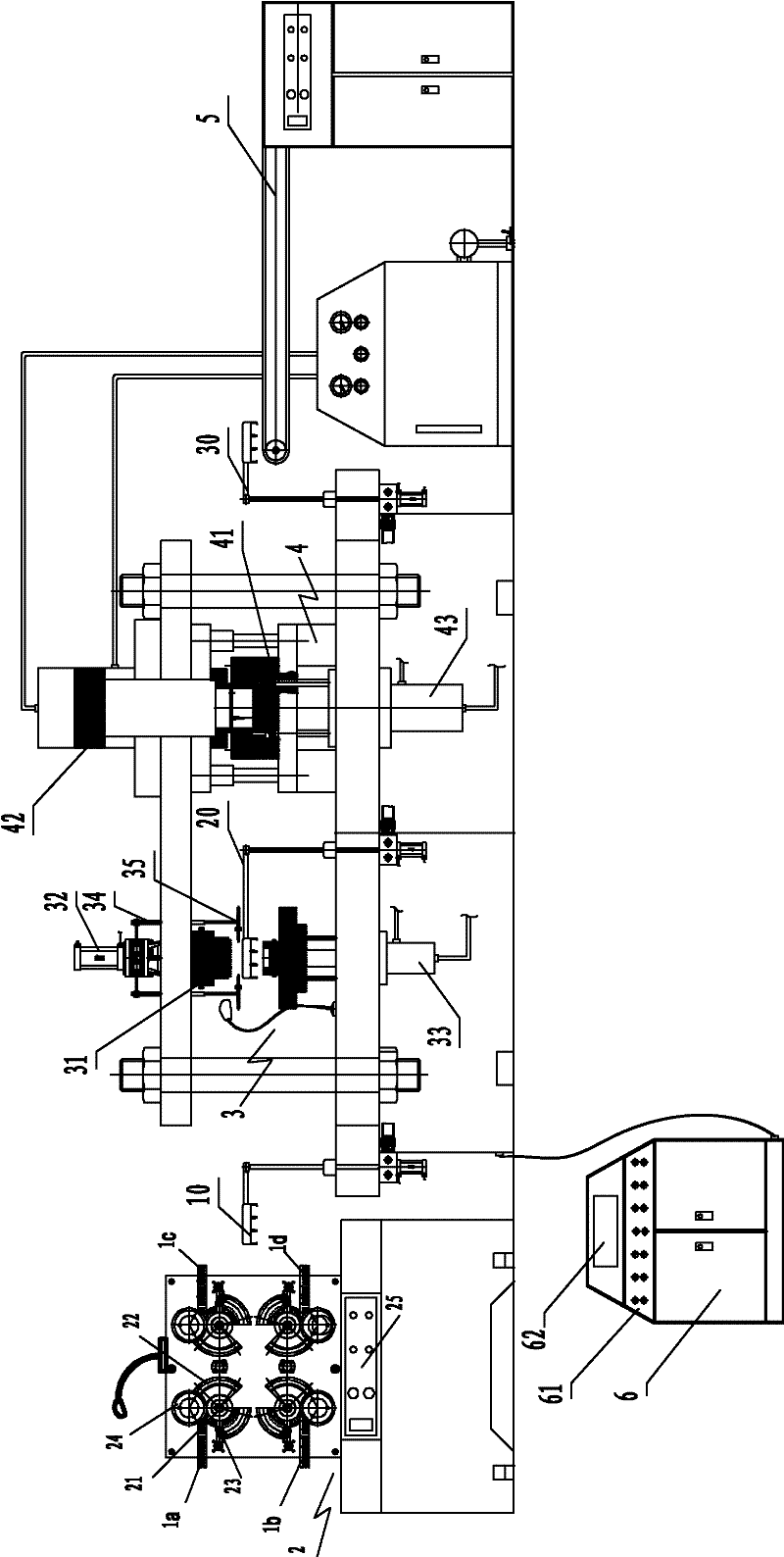

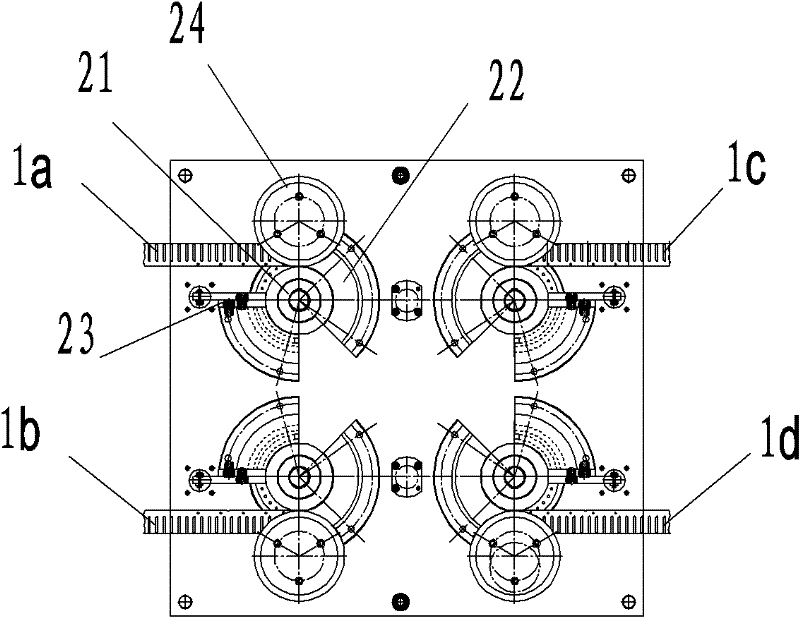

[0018] like figure 2 , image 3 As shown, will figure 1 The four strips 1a, 1b, 1c, and 1d that have been punched in the middle are connected to the stator core bending and forming integrated device 2, and the device 2 has four sets of forming devices including forming dies, forming sleeves, cutters, and cover plates ; Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com