Plane heat source

A heat source and heating element technology, which is applied in the field of surface heat source based on carbon nanotubes, can solve the problems of insufficient thermal response speed of thermoelectric materials, insufficient heating temperature of electrothermal materials, and inability to form carbon nanotube structures, etc., to achieve electrothermal conversion efficiency High, good heating performance, small thermal hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

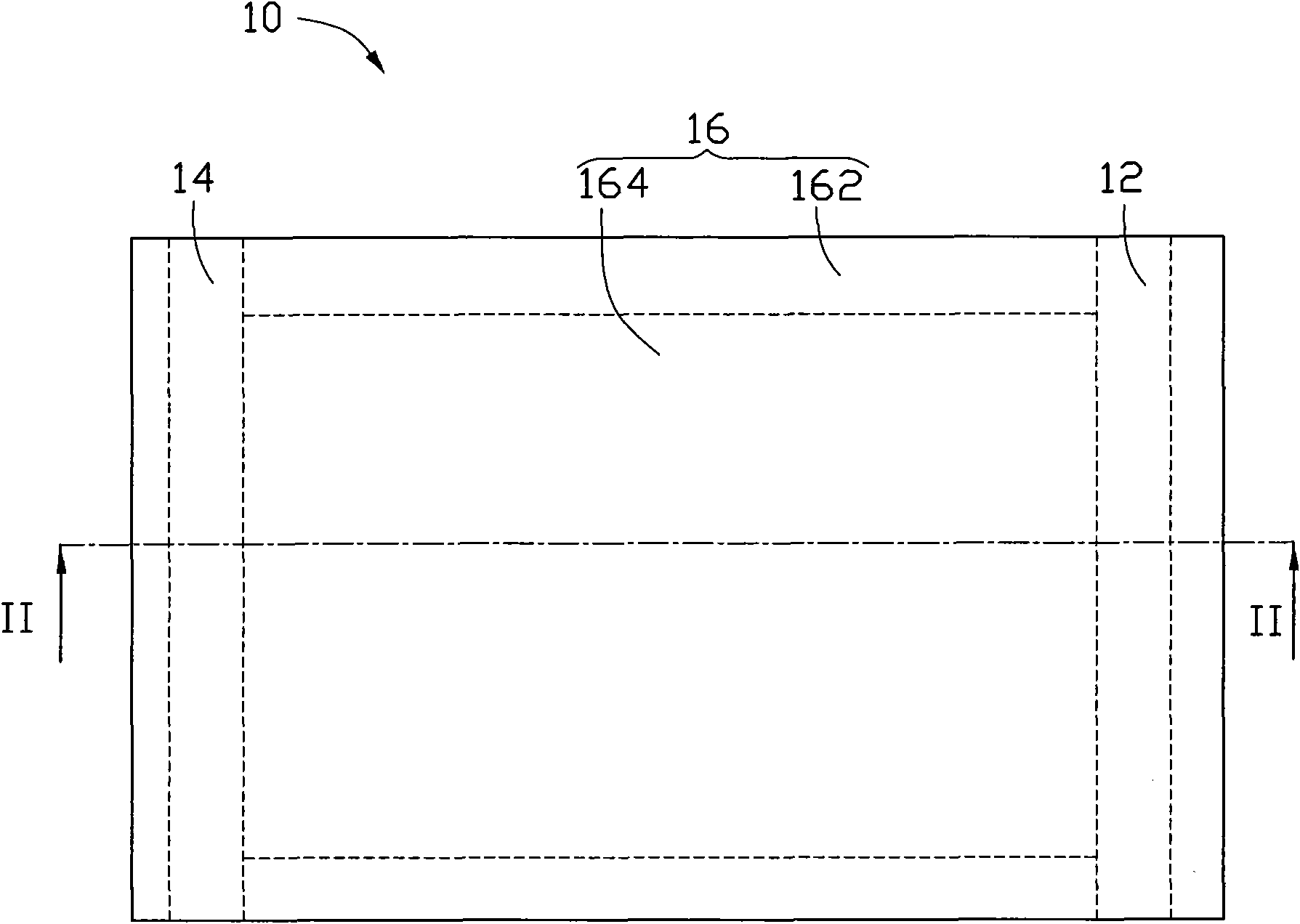

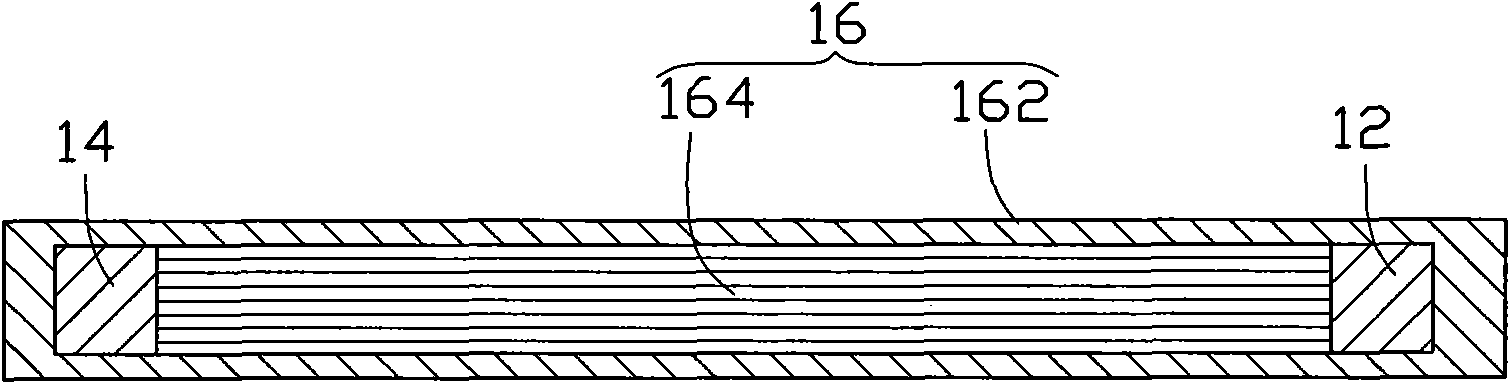

[0072] see Figure 18 , the embodiment of the present invention provides a method for preparing a surface heat source 10, which includes the following steps:

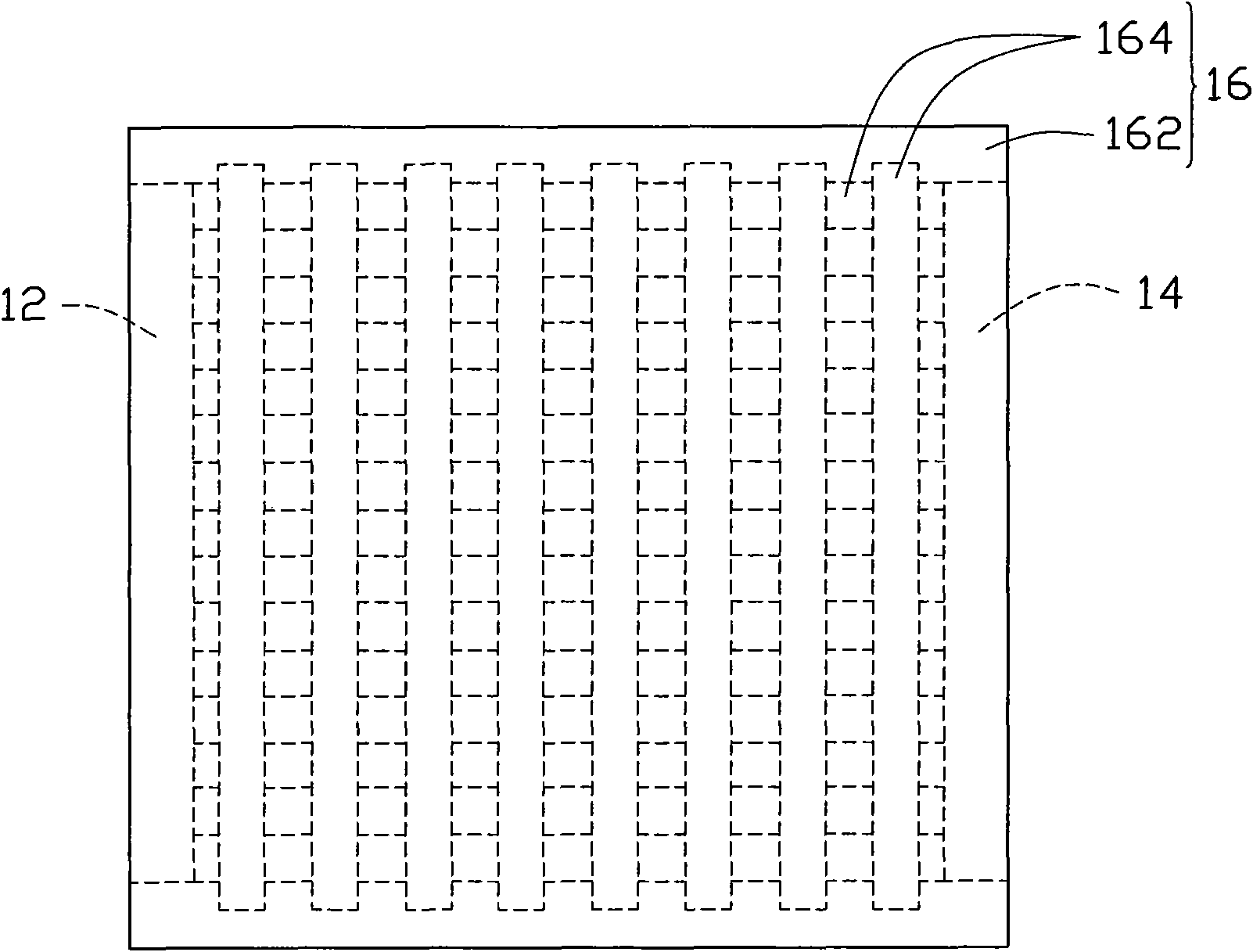

[0073] In step 1, a carbon nanotube structure 164 is provided, and the carbon nanotube structure 164 includes a plurality of pores.

[0074] According to the difference of the carbon nanotube structure 164, the preparation method of the carbon nanotube structure 164 includes: a direct film drawing method, a rolling method, a flocculation method and the like. In this embodiment, the carbon nanotube structure 164 can be a one-dimensional structure or a two-dimensional structure. The preparation methods of the above-mentioned several carbon nanotube structures 164 will be described separately below.

[0075] (1) When the carbon nanotube structure 164 includes at least one carbon nanotube drawn film, the preparation method of the carbon nanotube structure 164 specifically includes the following steps:

[0076] Firstly, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com