Landing flap mechanism driven by pinion gears

A pinion and flap technology, applied in the field of trailing edge flap devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

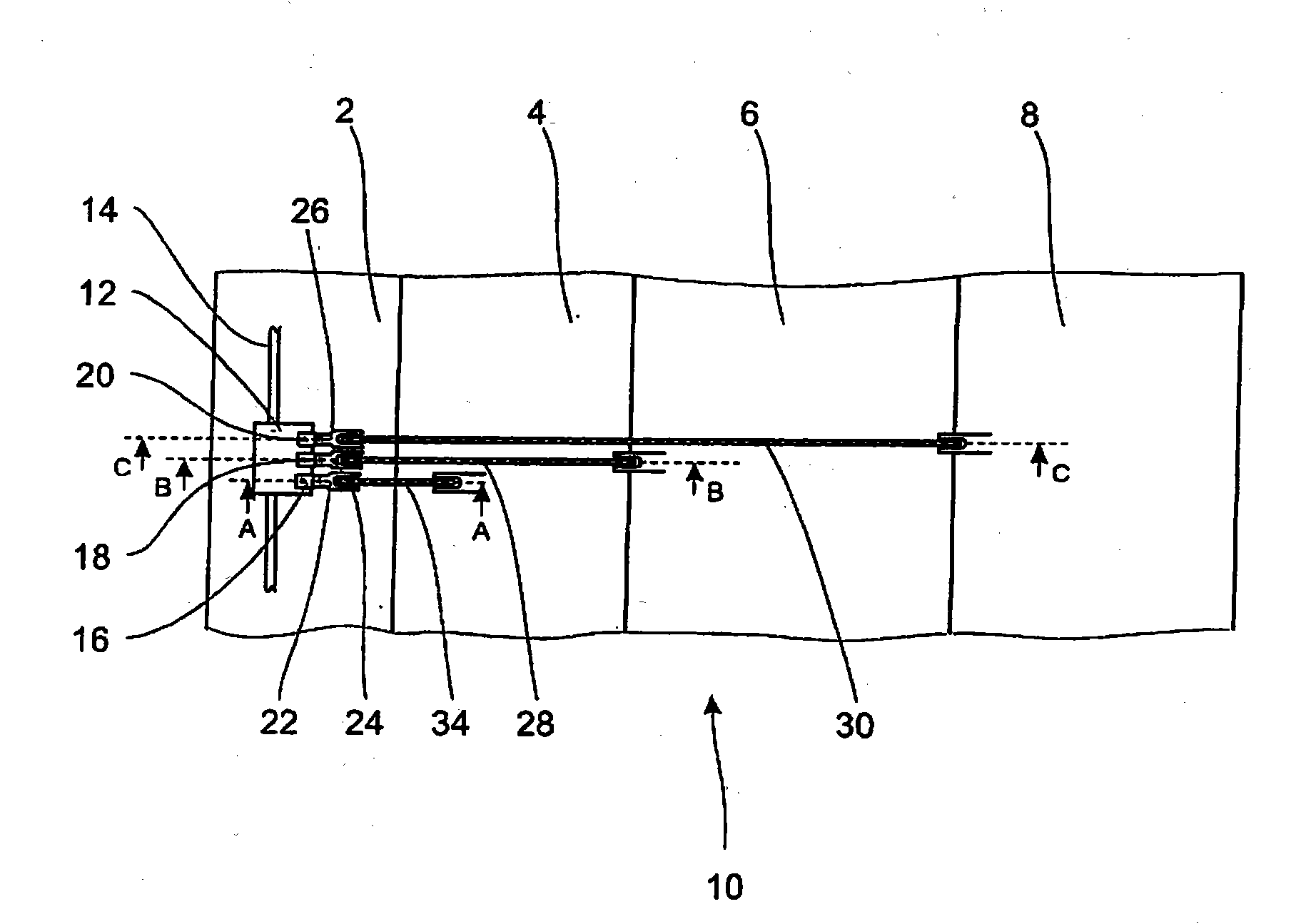

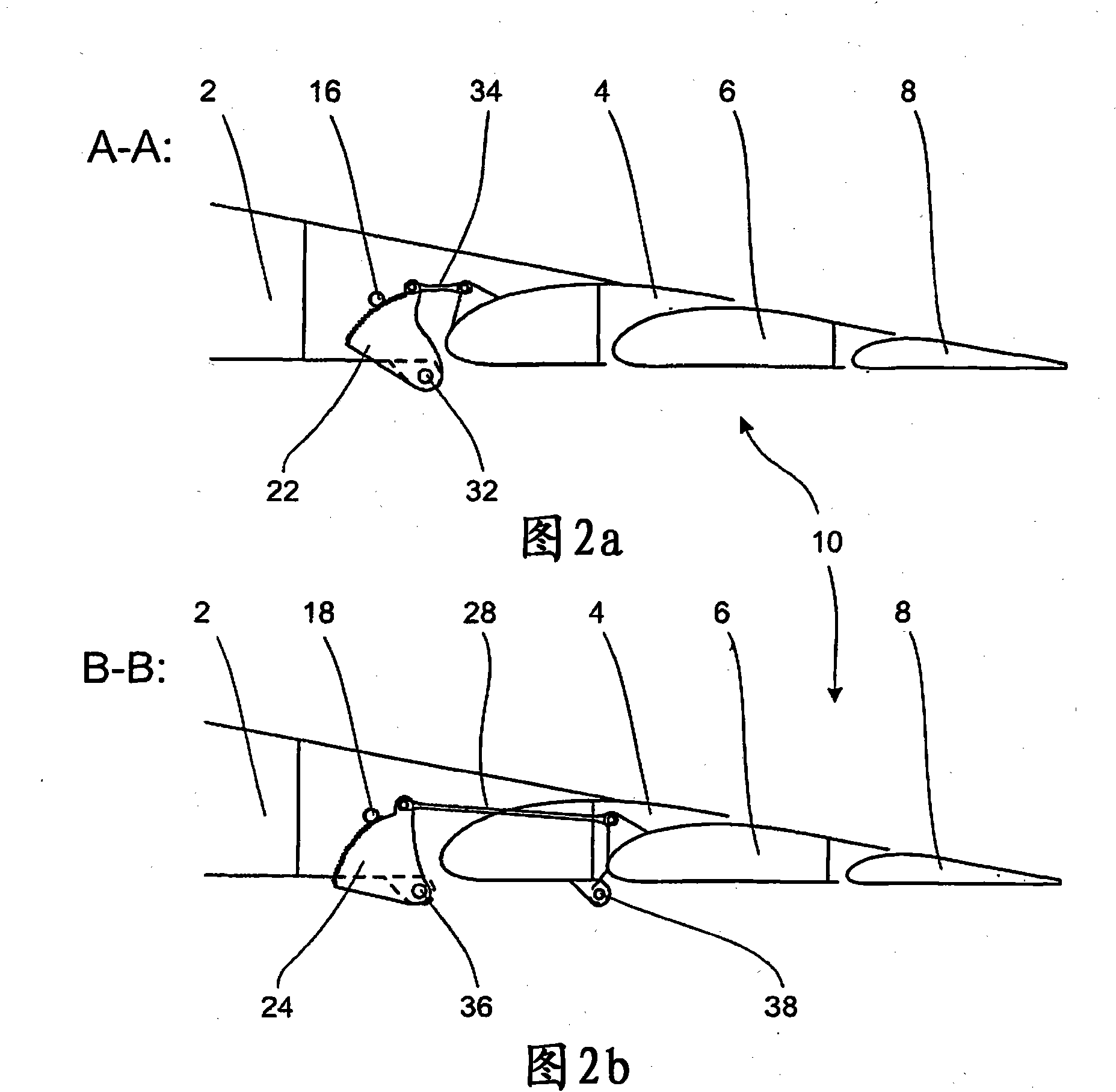

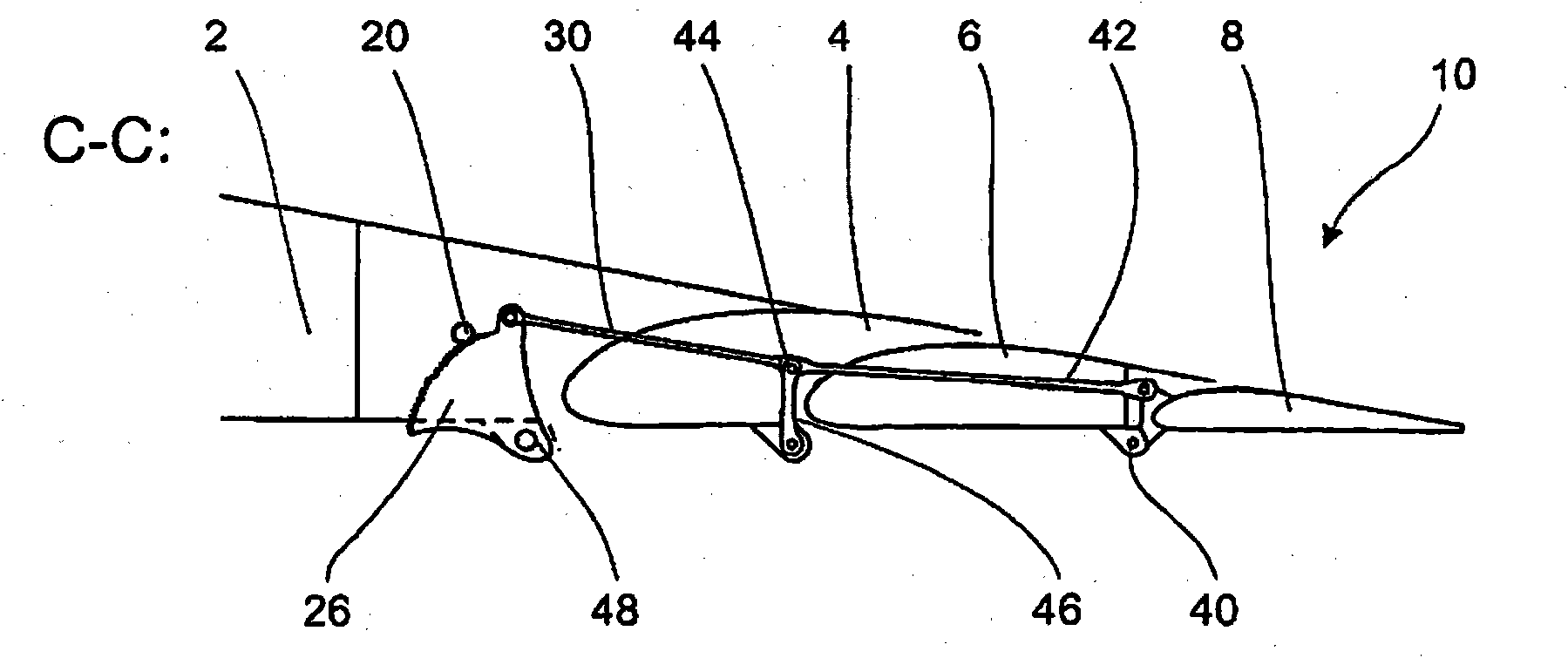

[0017] figure 1 Shown is a wing 2 with a trailing edge flap 10 consisting of three flap sections 4 , 6 and 8 . In the exemplary embodiment described, a central drive 12 is provided in a fixed manner to the wings, into which two drive shafts 14 , driven approximately by one or more electric motors, lead. Alternatively, the drive can take place via a central hydraulic drive, such as in conventional high-lift systems with shaft drives for both wings. In the alternative to the shaft drive, a shaft guide to the wing-fuselage transition is necessary.

[0018] The central drive 12 drives three pinions 16, 18 and 20 which in turn engage in three toothed discs 22, 24 and 26 which Preferably there are teeth on the circumferential parts facing the respective pinions 16 , 18 and 20 . Sprockets 22, 24 and 26 are mounted on the bottom of the central drive 12 or on the wing 2 figure 1 at the hinge point not shown. Pinions 16 , 18 and 20 provide drive torque and motion to flap segments 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com