New method and system for determining characteristic curve of water pump in pump station

A technology for determining the characteristics and methods of water pumps, applied in pump testing, liquid displacement machinery, machines/engines, etc., can solve problems such as high cost, impact load of pipe network and pump station operation, improve management level, avoid Shock load, the effect of saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

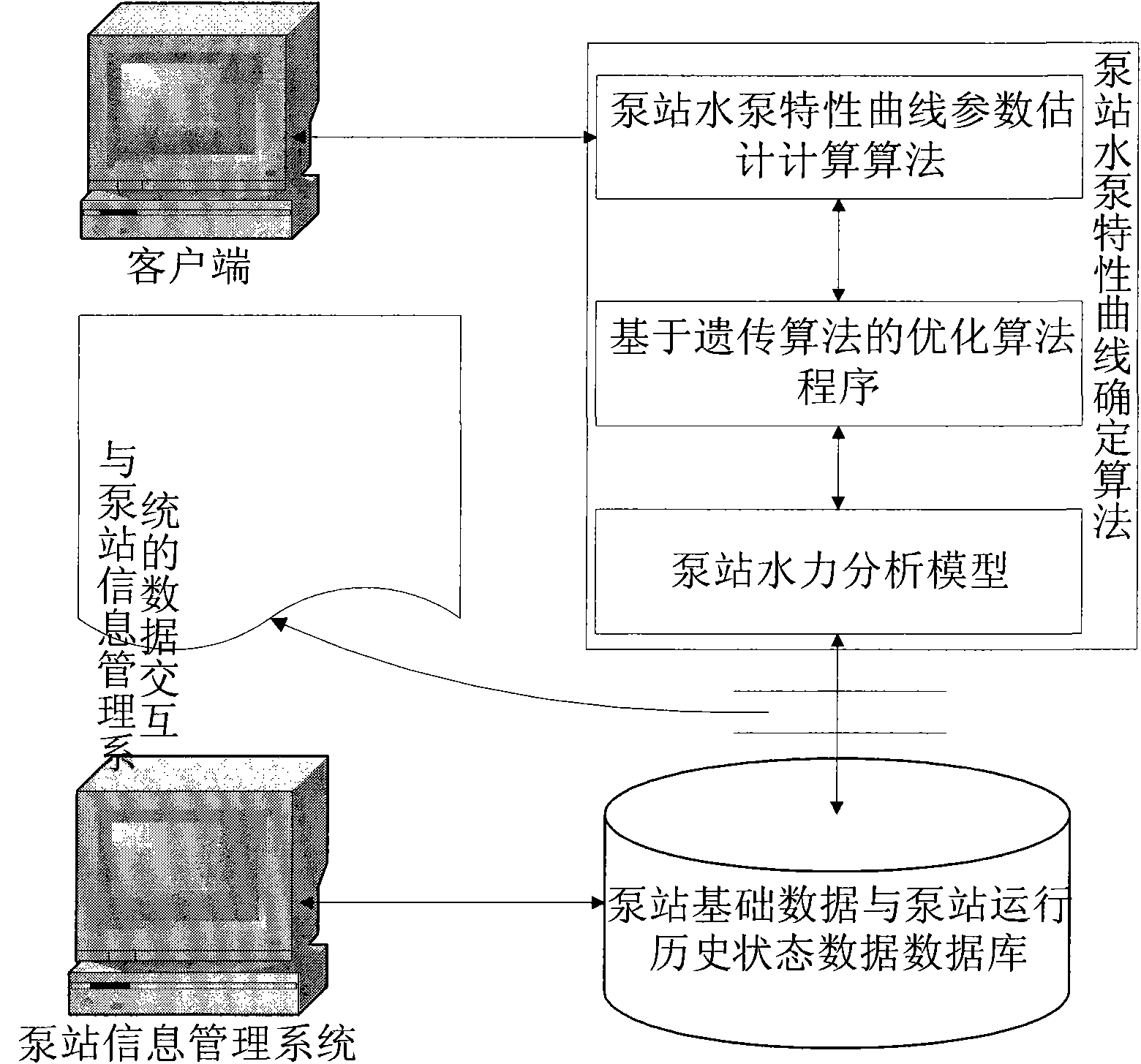

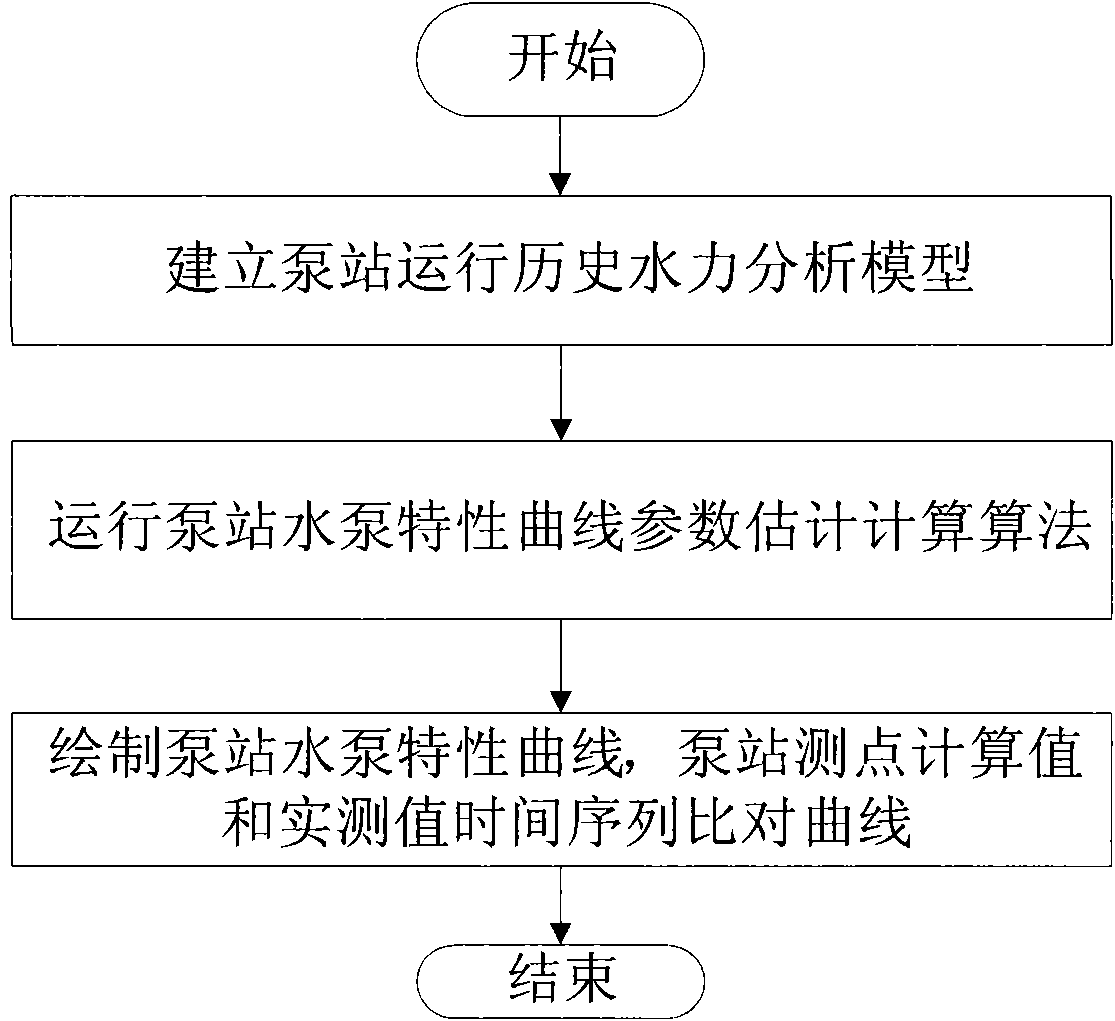

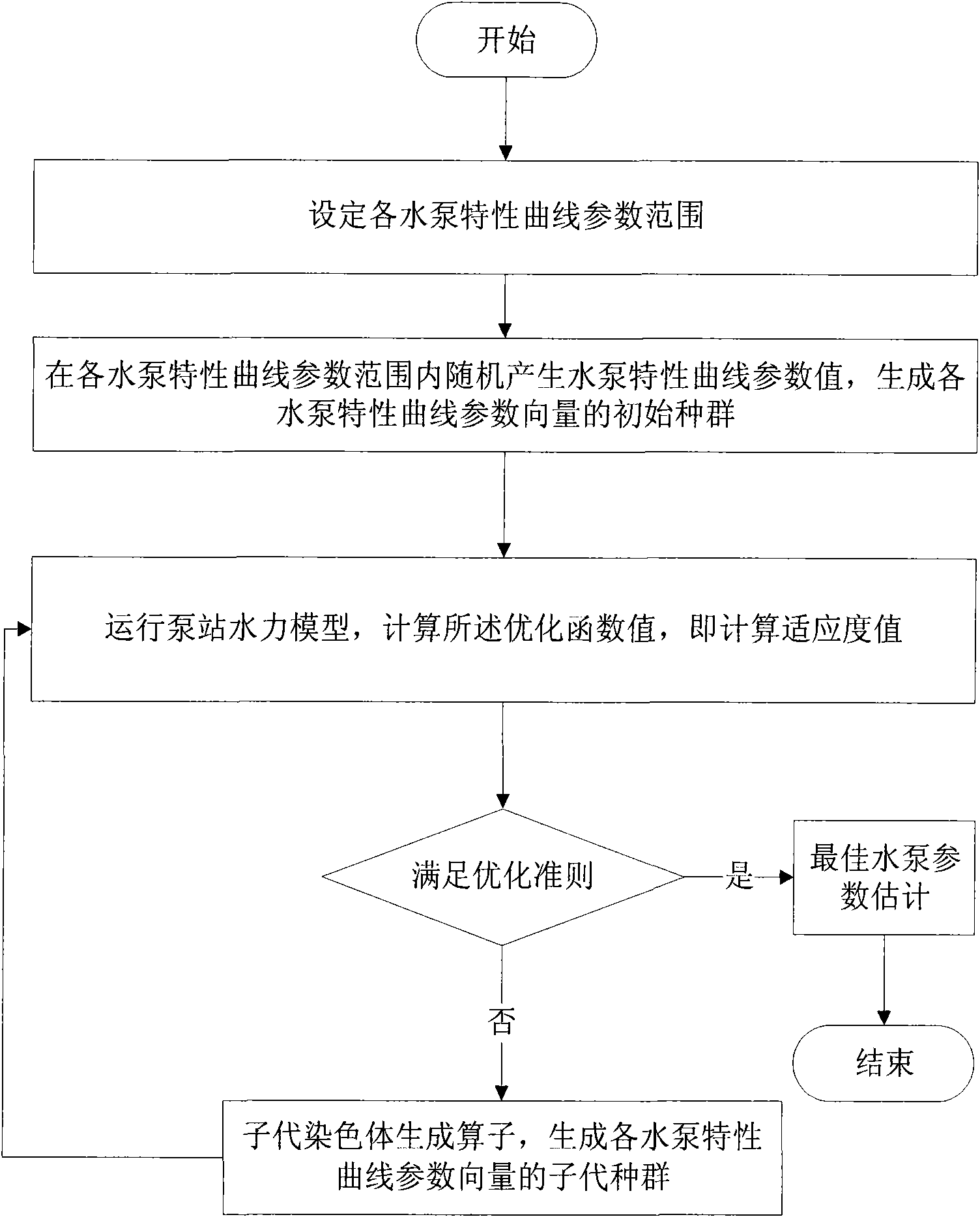

[0045] In practice, due to the needs of pumping station management, flow sensors and pressure sensors are generally installed on the outflow main pipe of the pumping station, and water level sensors are installed in the suction well or in the clean water tank of the water plant. In addition, in the water pump, the water pump inverter , There are also relevant sensors on the control valve to record the operation switch status of the pump, the operation frequency of the pump motor, and the change of the opening of the control valve. These facilities record the operation status of the pump station, and form the daily operation history data of the pump station to be stored in the database. The present invention uses the daily operation historical state data of the pumping station to determine the characteristic curve of the water pump in the pumping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com