Shaft housing for heavy vehicle equalizing suspension and bus leaf spring suspension and manufacturing method thereof

A technology of balanced suspension and leaf spring suspension, which is applied to springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., which can solve the problem of high manufacturing cost of bimetal bushings, failure to meet operating requirements, and easy occurrence of Abnormal sound and other problems, to achieve the effect of improving ride comfort and running stability, light weight, and reducing abnormal sound problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The accompanying drawing shows a specific embodiment of the present invention, and the present invention will be further described below through the accompanying drawing and the embodiment.

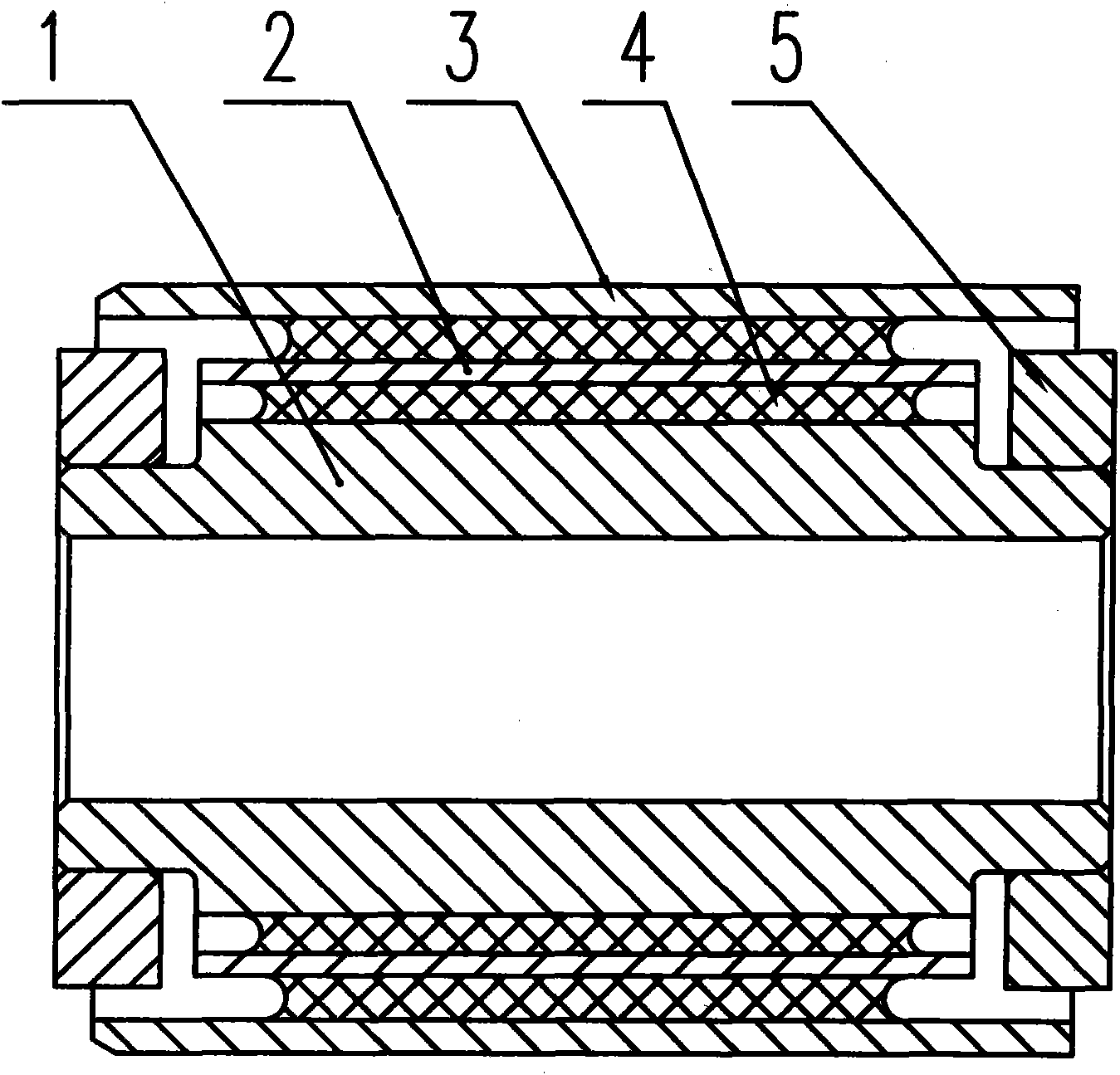

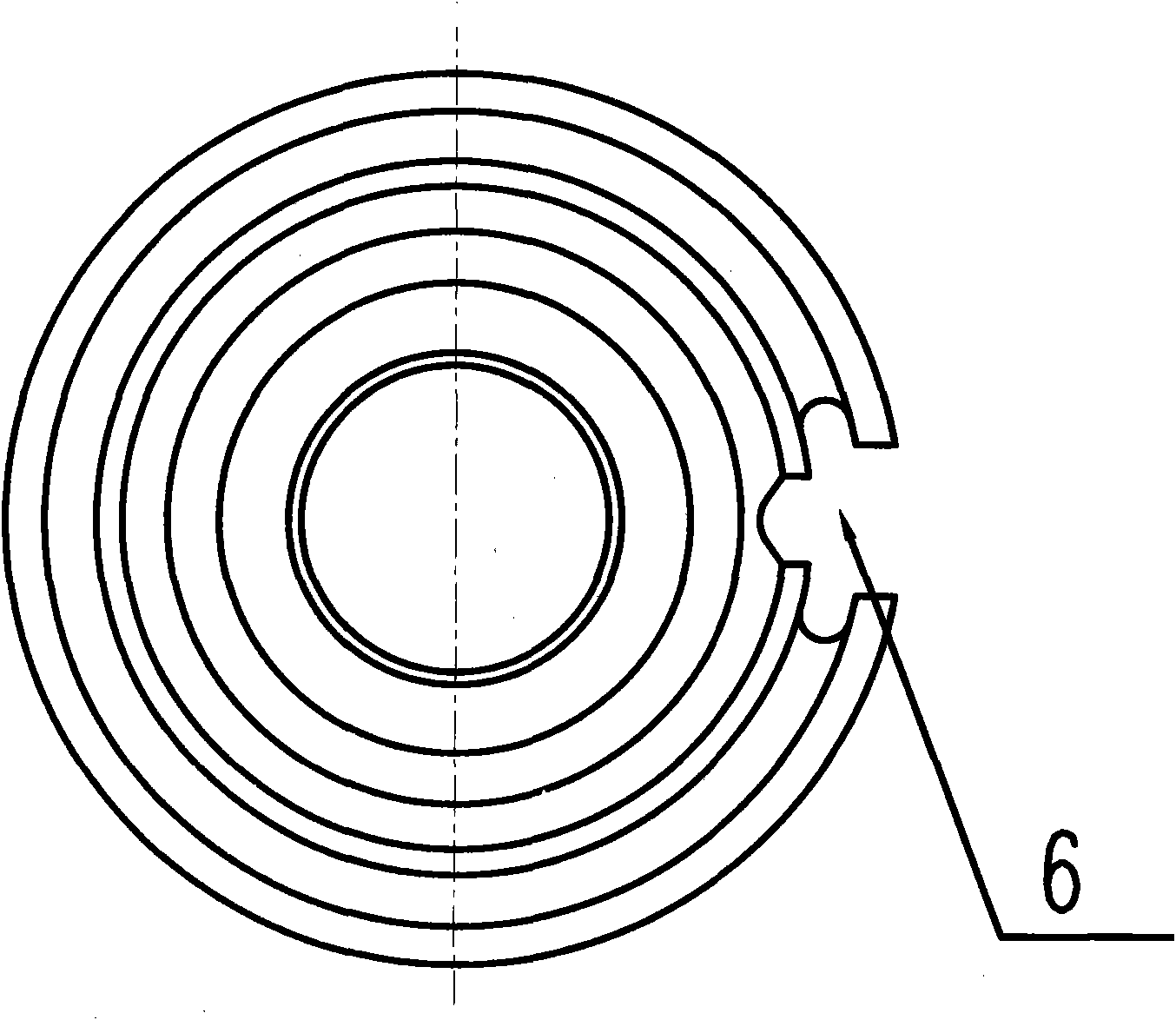

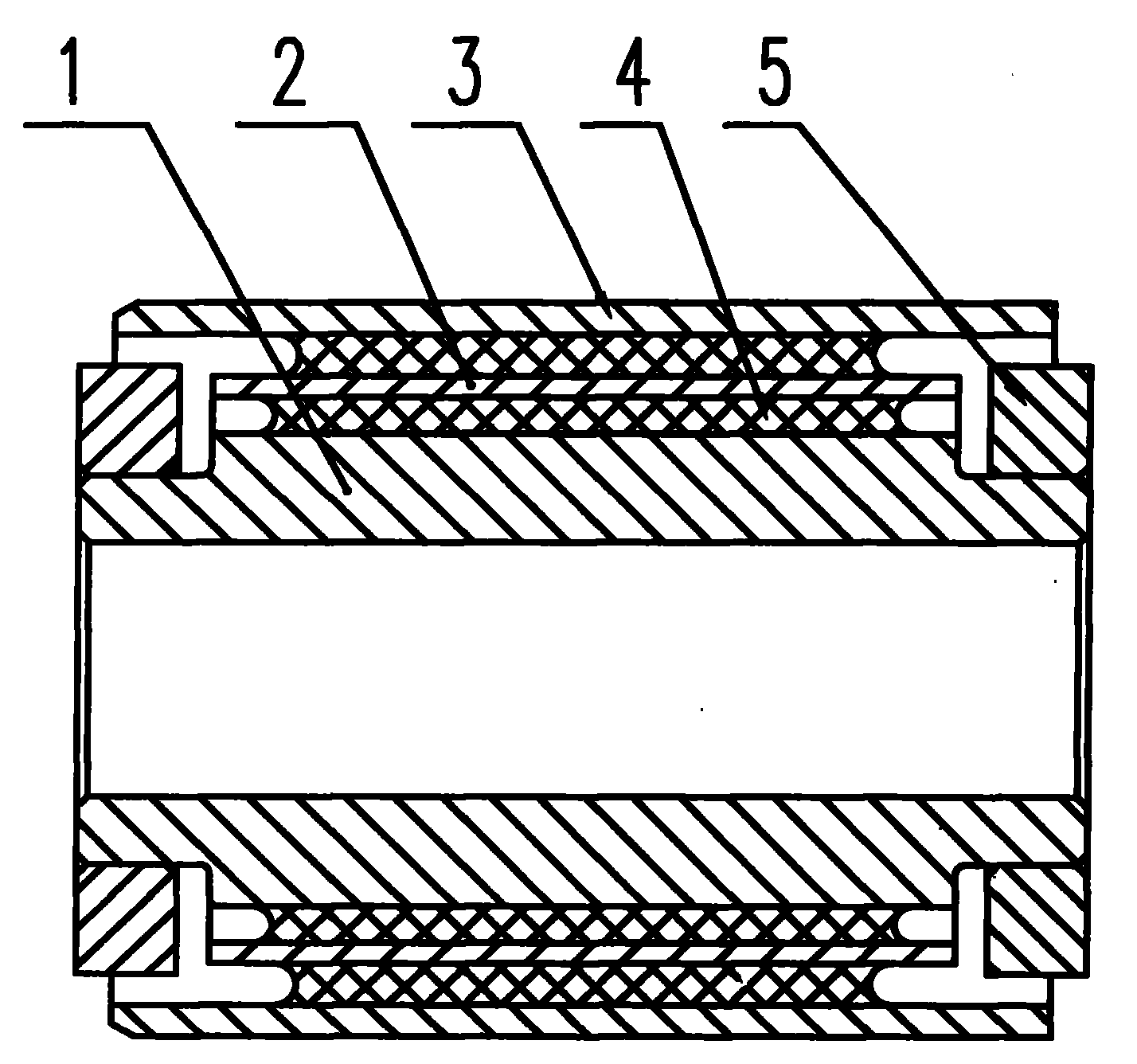

[0026] figure 1 A specific embodiment of the present invention is given, and it can be seen from the accompanying drawings that the present invention is a connecting bush between the leaf spring of the heavy-duty automobile balance suspension and the passenger car leaf spring suspension system and the suspension lug of the vehicle frame. An elastic bushing combined with an open rubber elastic element and a metal retaining ring, including a metal mandrel 1, a spacer 2, a jacket 3, a retaining ring 5 and two layers of elastic rubber body 4, and the spacer is in two layers of elastic rubber Between the bodies, the metal mandrel 1, the spacer 2, the jacket 3 and the elastic rubber body 4 are vulcanized together; wherein, the spacer 2 is between two layers of elastic rubber bodies 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com