Thin plastic film splitting machine

A technology of plastic film and slitting machine, applied in the field of machinery, can solve the problems of operator fatigue, low production efficiency, frequent material change, etc., and achieve the effect of reducing labor intensity, improving utilization rate and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

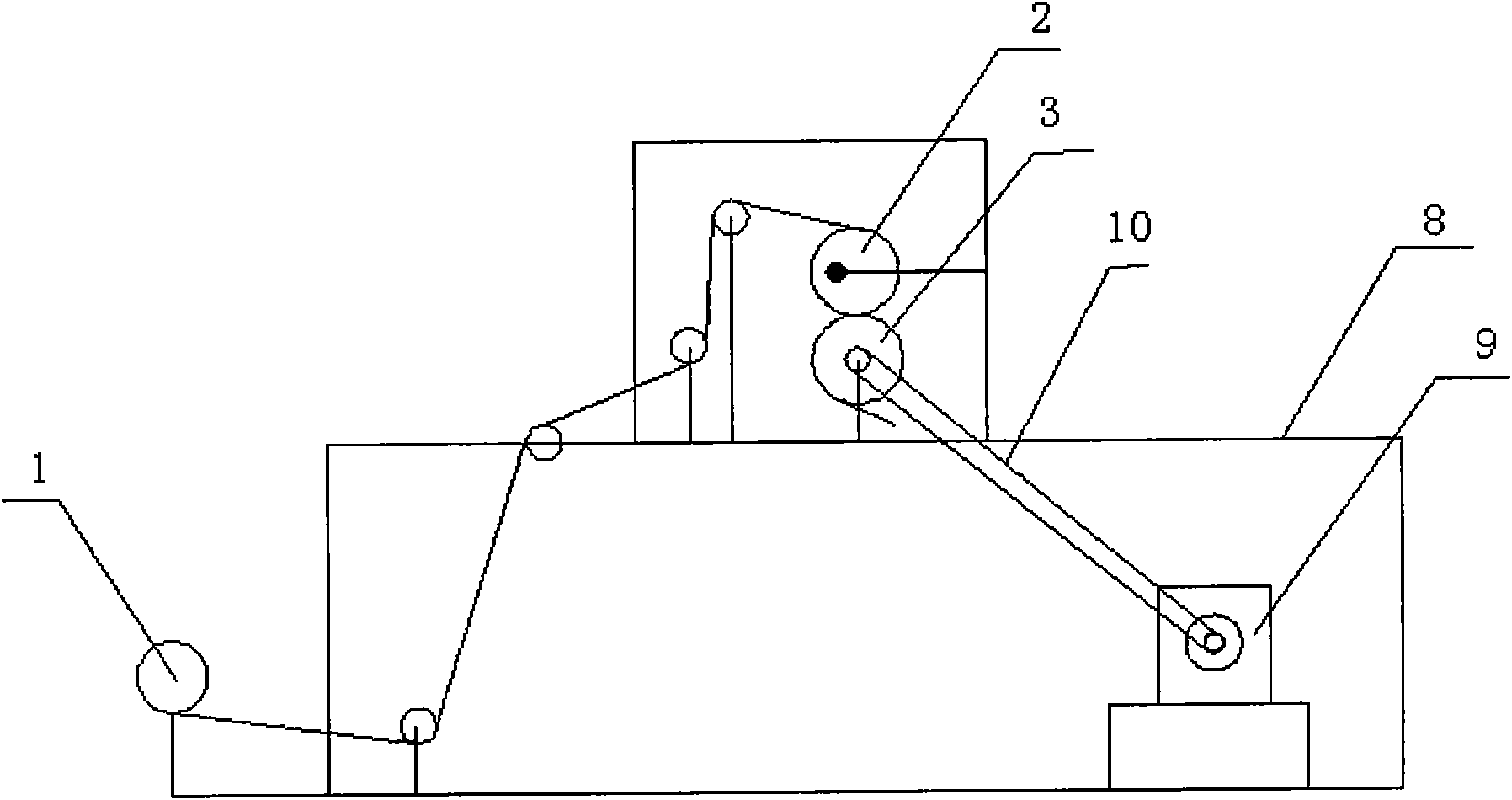

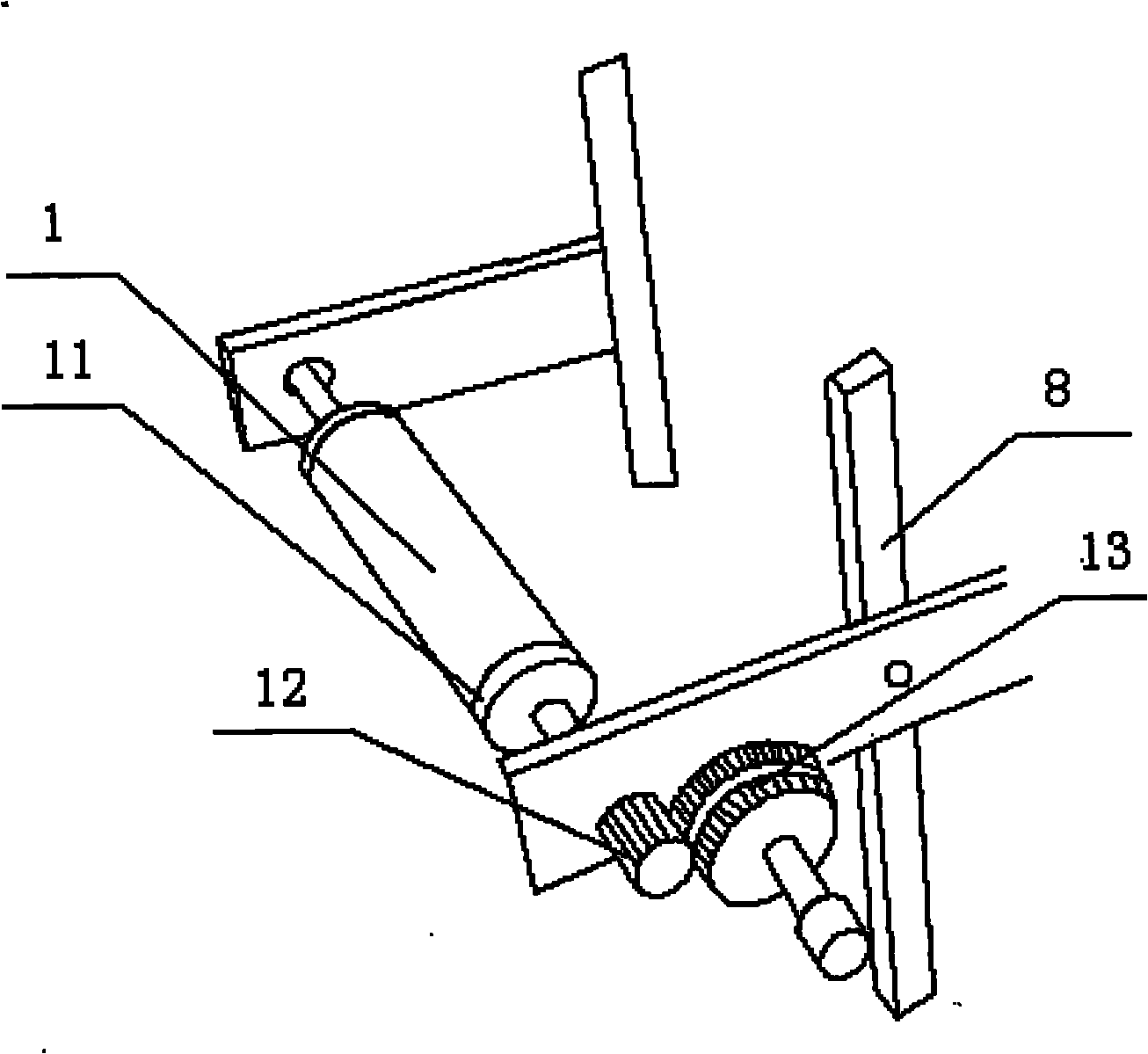

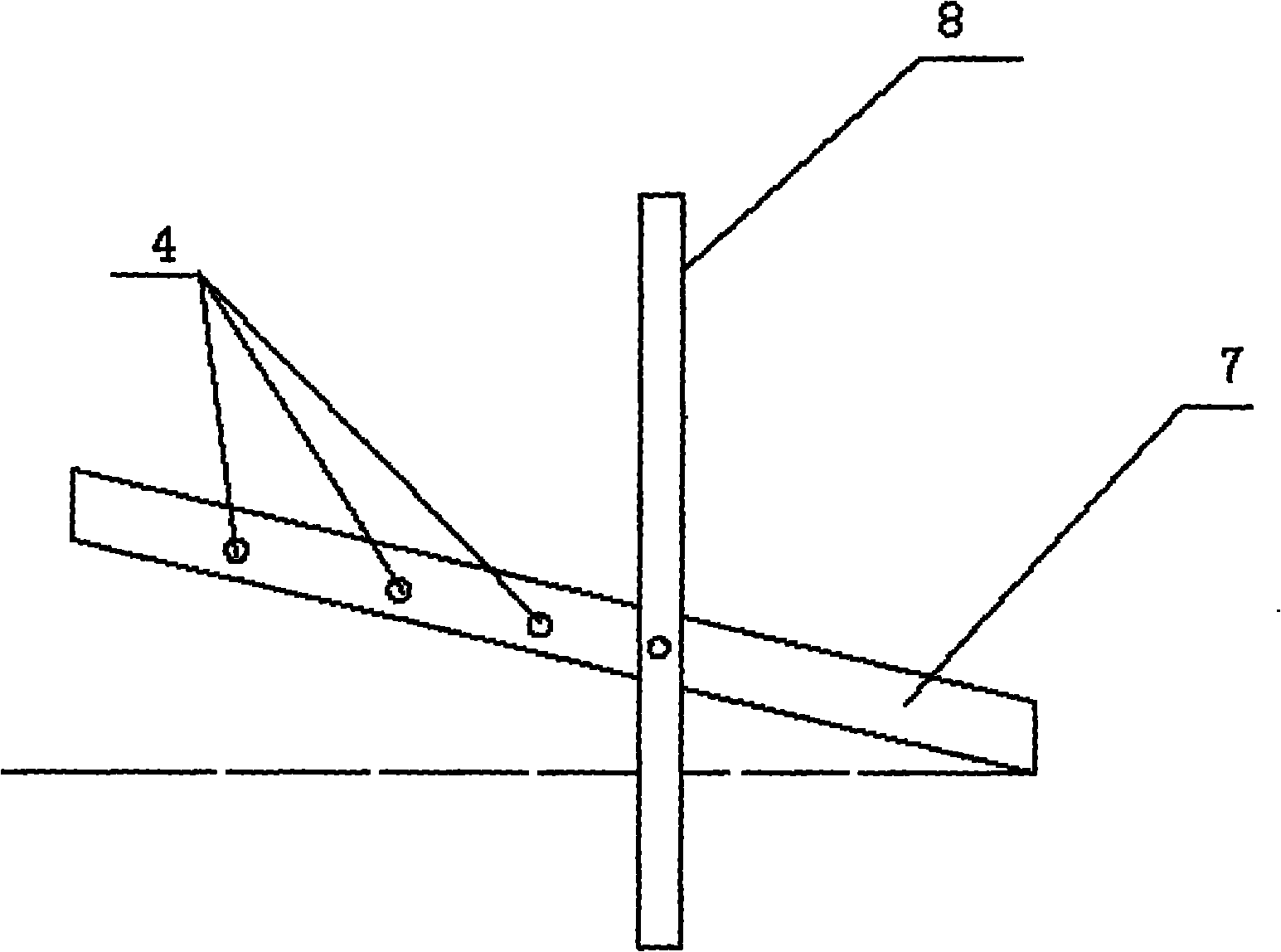

[0027] The thin plastic film slitting machine includes a bracket, a feeding mechanism, a stretching mechanism, a cutting mechanism and a winding mechanism, wherein the feeding mechanism and the winding mechanism are arranged on the front and rear sides of the bracket, and the cutting mechanism is arranged on the top of the bracket. The stretching mechanism is respectively arranged between the feeding mechanism and the slitting mechanism, and between the winding mechanism and the slitting mechanism.

[0028] figure 1 It is a structural schematic diagram of the feeding mechanism described in the present invention.

[0029] Such as figure 1 As shown: the feeding mechanism includes a coil shaft 1 arranged at one end of the bracket 8 and two rubber cylinders arranged on the upper part of the bracket 8, the two rubber cylinders are in vertical contact and rotate in the same direction, and the driving motor 9 arranged at the bottom of the bracket 8 passes through The chain 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com