Side power all-drive near suspension railway train system

A rail train and power system technology, which is applied in the field of side power full-drive near-suspension rail train system, can solve the problems of speed rating power limitation, difficult speed control, and failure to form a road network, etc., to achieve the effect of increasing air lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

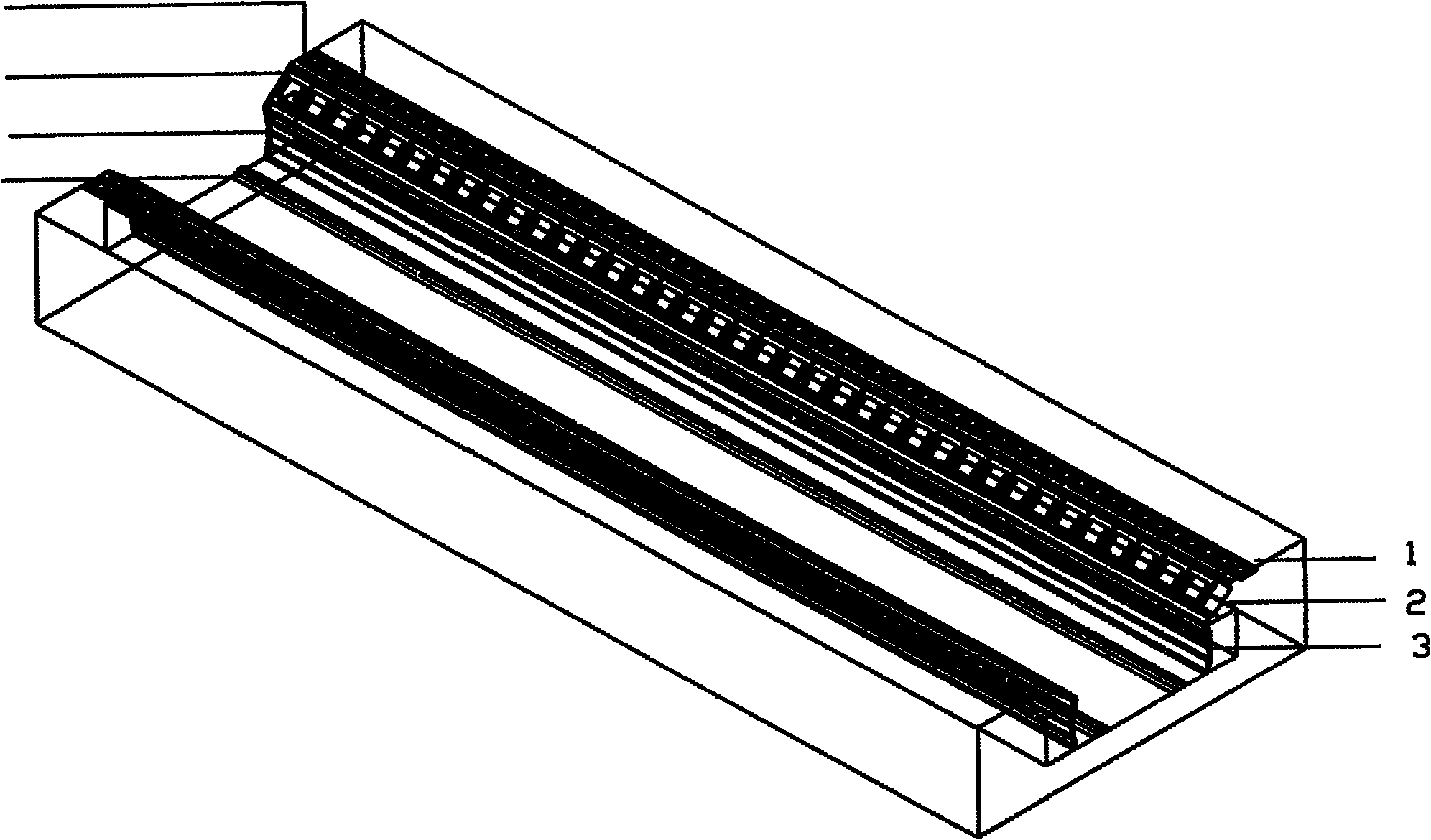

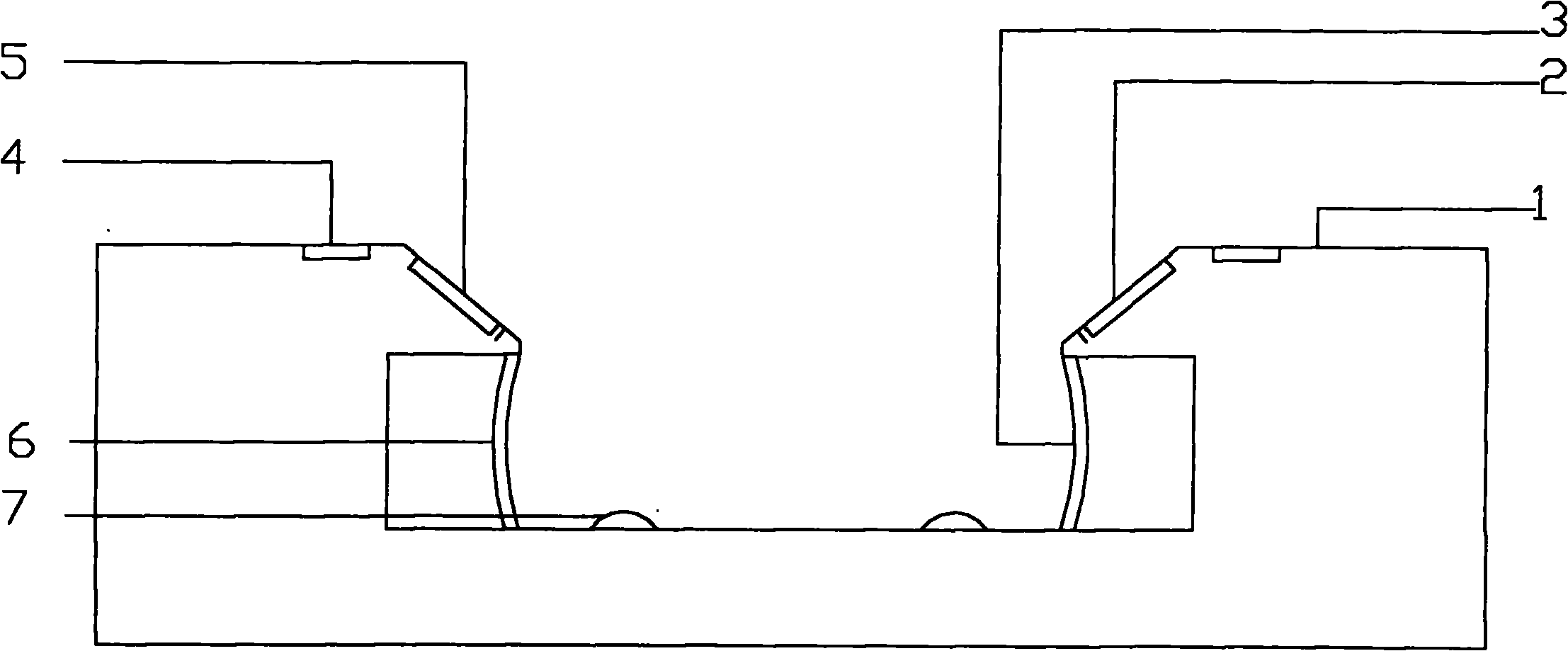

[0030] exist figure 1 and figure 2 Among them, the concave track is poured with reinforced concrete and laid directly on the ground. Install and paste the stainless steel plate (6) on the lower half curved wall (3). Electric heating pipe (7) is generally installed on track bottom, also can be installed on track plane (1) or slope (2), because these places are the places that accumulate snow and icing easily. There must also be some drainage pipes and channels to remove the sludge at the bottom of the track. A strong magnet block A (4) and a strong magnet block B (5) are respectively installed on the concave track plane (1) and the slope (2).

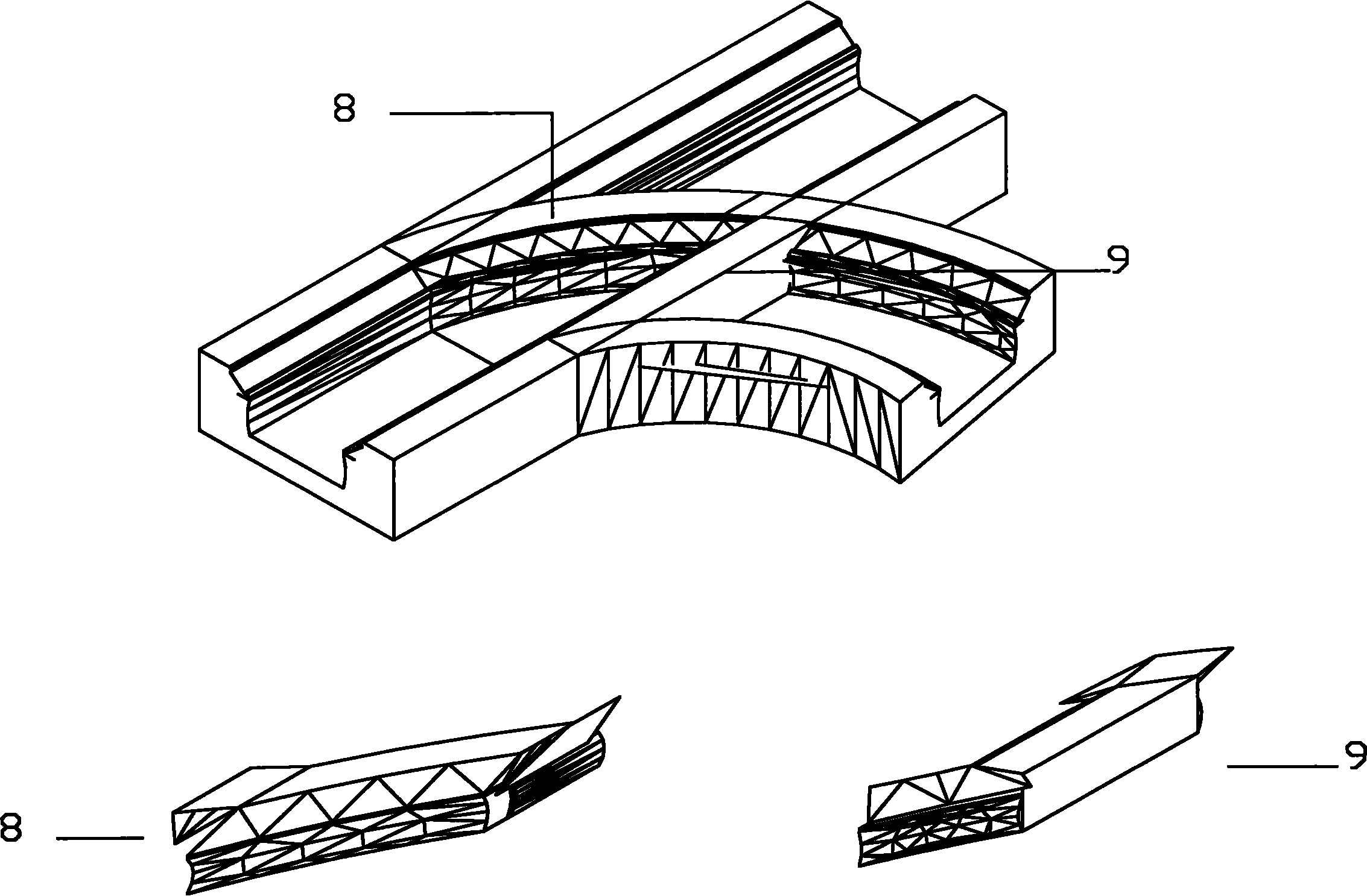

[0031] exist image 3 Among them, the lifting gate rails (8) and (9) must be equipped with a lifting mechanism, which is hidden at the bottom of the track when not in use. When in use, the lifting mechanism moves the gate rail (8) or (9) to a position that matches the running track and Fix it so that the train can pass through smoo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap