Sleeving device for a valve bag

A valve bag and set technology, applied in the field of separating devices and aligning devices, to achieve the effects of increasing rhythm frequency, high durability, and shortening rhythm time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

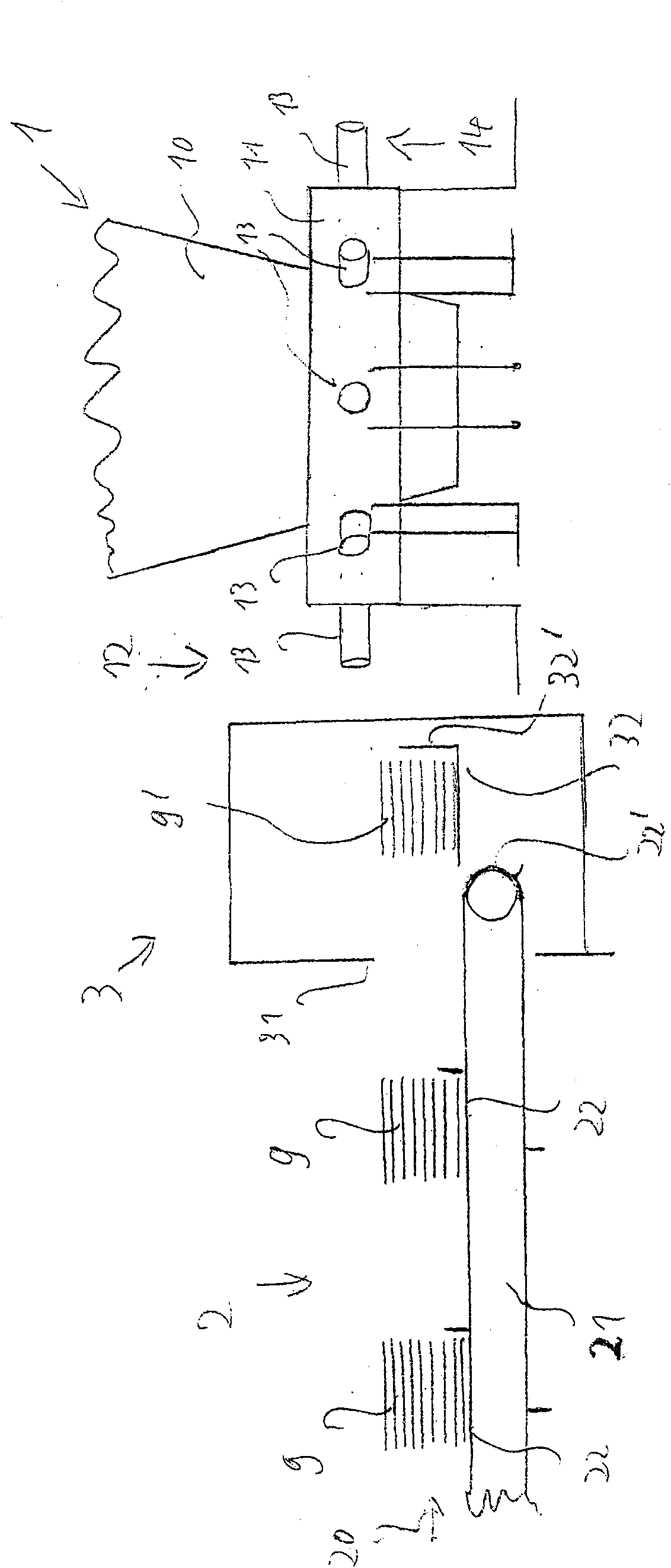

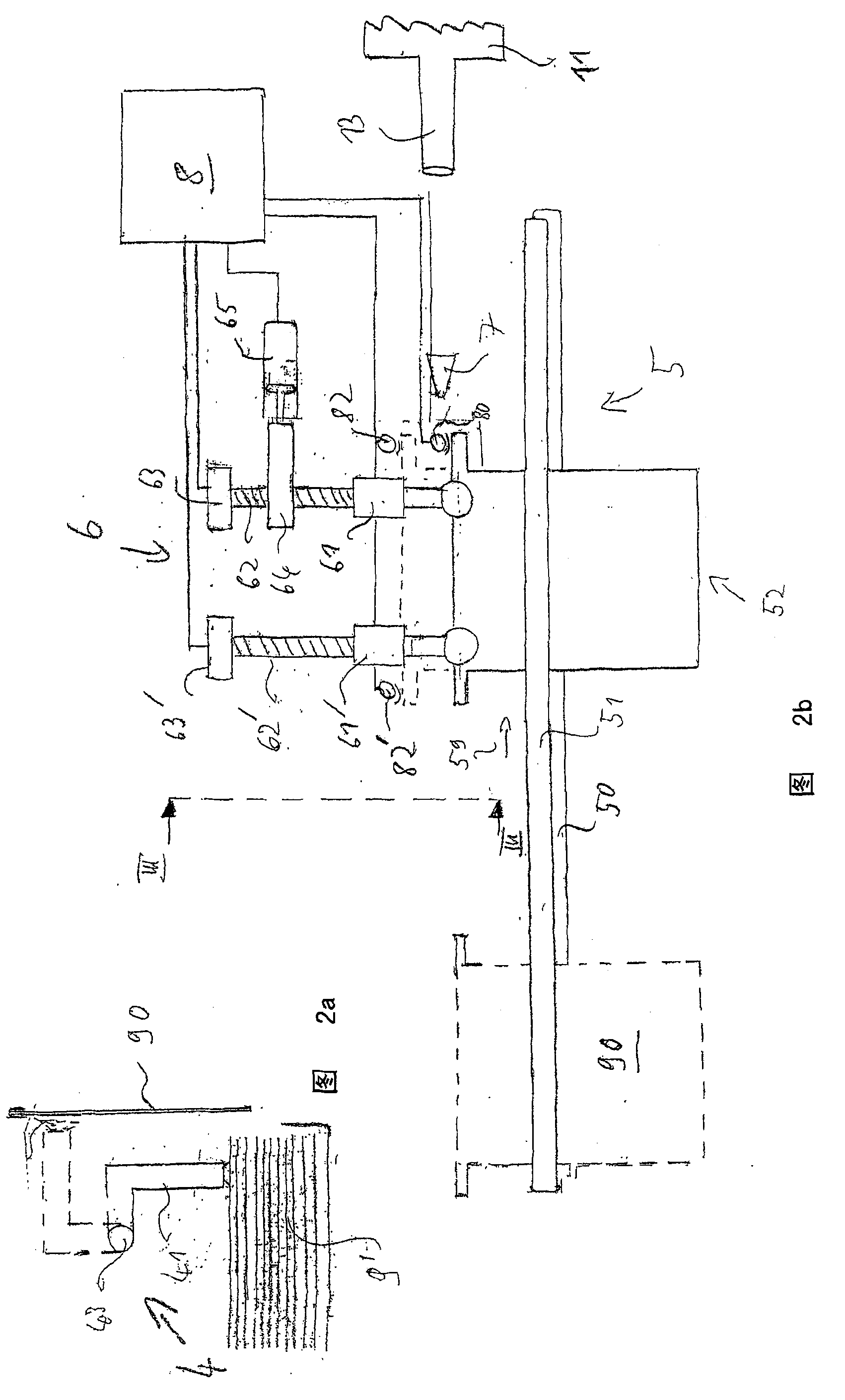

[0025] According to one embodiment of the invention, the kit (Aufsteckvorrichtung) is embedded in the filling device, as in figure 1 It is shown schematically in . The filling plant comprises a filling machine 1 , a supply device 2 for stacks of valve bags and a set-up device 3 .

[0026] The filling machine 1 has a silo 10 for the flowing material to be packaged, such as cement, the lower end of which is only partially shown in the figure. A filling star 11 is provided at the lower end of the magazine. The filling star has a plurality of filling tubes 13 pointing radially outward. According to the embodiment shown, the filling star 11 rotates around the stationary part of the silo 10 with the filling machine 1 forming the different stations. At the fitting station 12 facing the fitting device 3 , the separate valve bags are each fitted onto the filling tube 13 . The filling star 11 continues to rotate, during which time the valve bag is filled through the filling pipe 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com