Device and method for detecting dispersing performance of chemical synthesized short fibers

A technique of dispersing performance and chemical synthesis, which is applied in the inspection of textile materials, textiles and papermaking, etc., and can solve the problem of inability to separate or sort out defects such as small parallel or small continuous sticky yarns, inaccurate test results, and distorted test results, etc. problems, to achieve the results of true and reliable detection results, accurate detection, and rapid detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

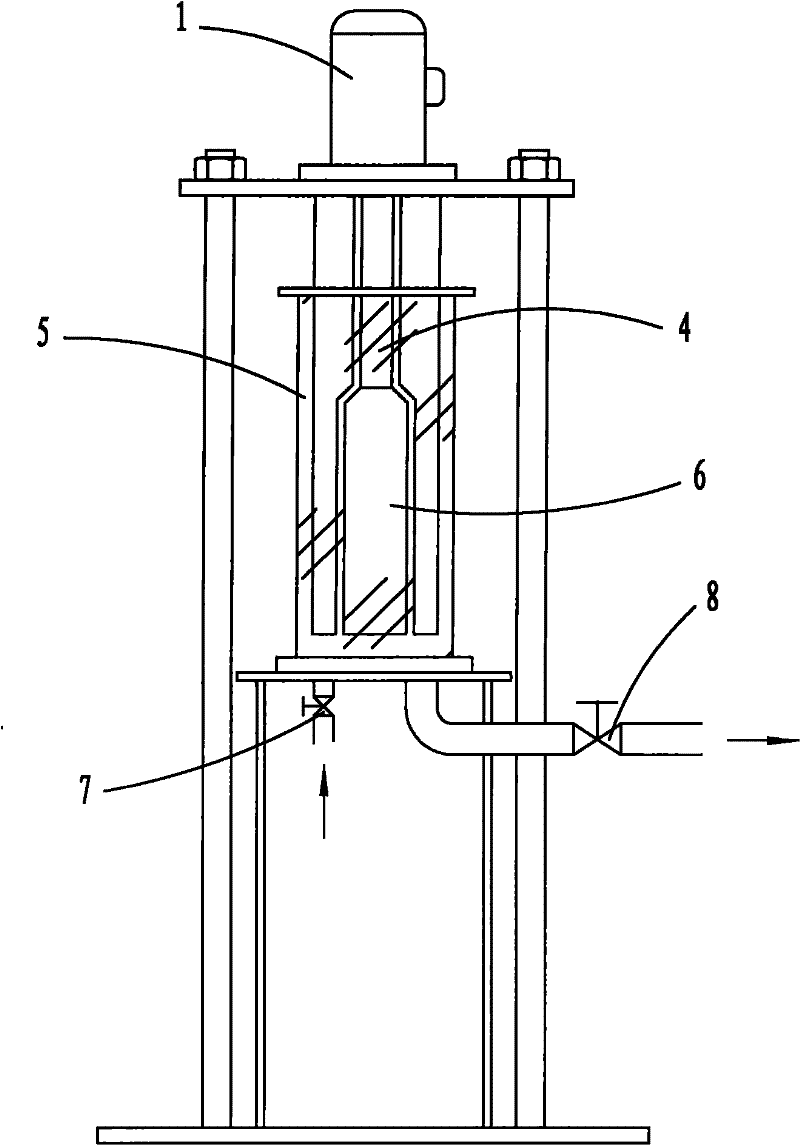

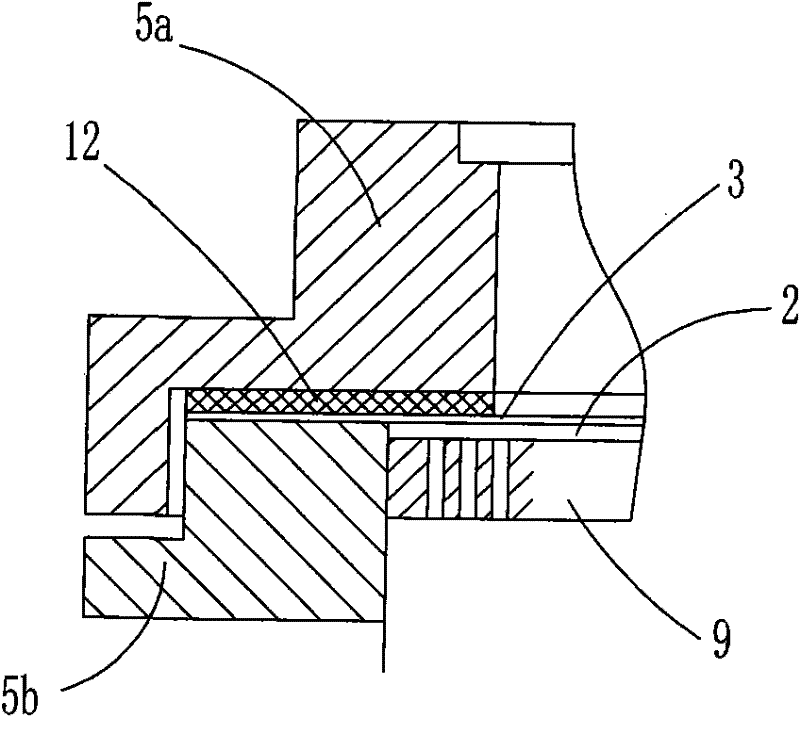

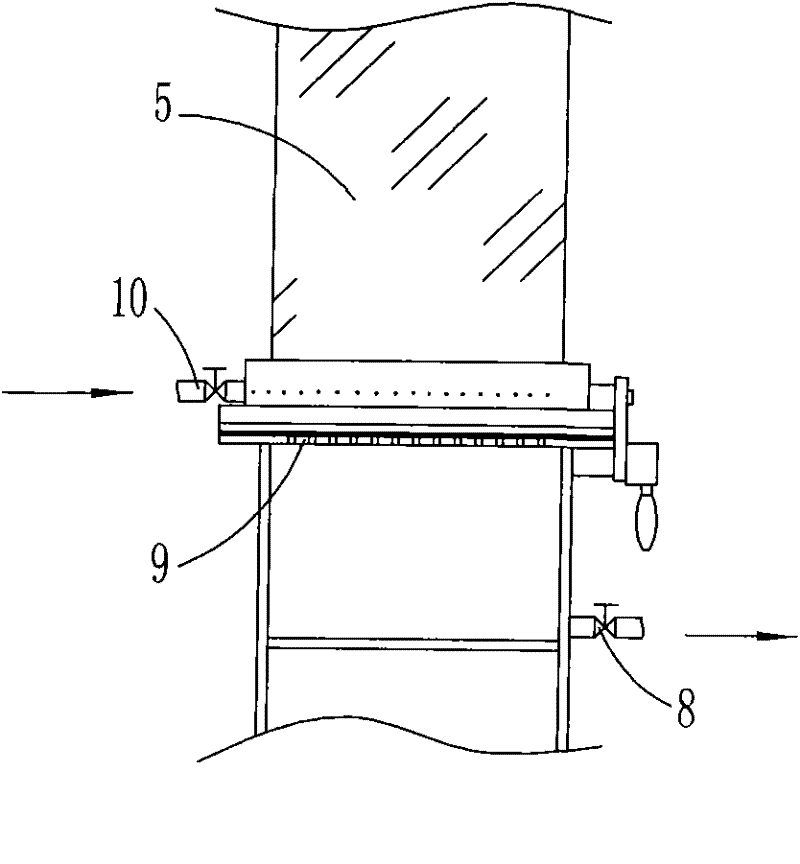

[0028] see figure 1 , figure 2 , a cylindrical tube 5 is set upright, and an intermediate filter layer is arranged in the cylindrical tube 5. Above the intermediate filter layer, an agitating shaft 4 is arranged in the axial direction for installing a stirring paddle 6 to form a dispersing agitator. Below, the water inlet pipe installed with the water inlet valve 7 and the liquid discharge pipe installed with the liquid discharge valve 8 are respectively arranged. The middle filter layer includes the filter screen 2 and the filter cloth 3 placed on the filter screen 2. The filter screen 2 adopts 25 mesh Stainless steel mesh, because the short fibers are white, black filter cloth should be used for easy observation; on the side wall of the cylinder 5, located at the bottom of the stirring shaft 4 and above the middle interlayer, the air inlet pipe is arranged radially 10. The driving motor 1 of the stirring shaft 4 adopts an overhead structure, and the driving motor 1 mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com