Constant-speed transmission shaft with telescopic middle shaft

A constant-speed transmission, intermediate shaft technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of large circumferential transmission clearance, poor sliding effect of the intermediate shaft, and bending moment force on the gearbox end. Large and other problems, to achieve the effect of large axial space, increased expansion and contraction, and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

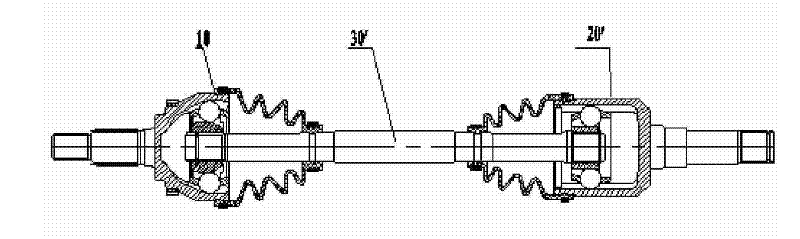

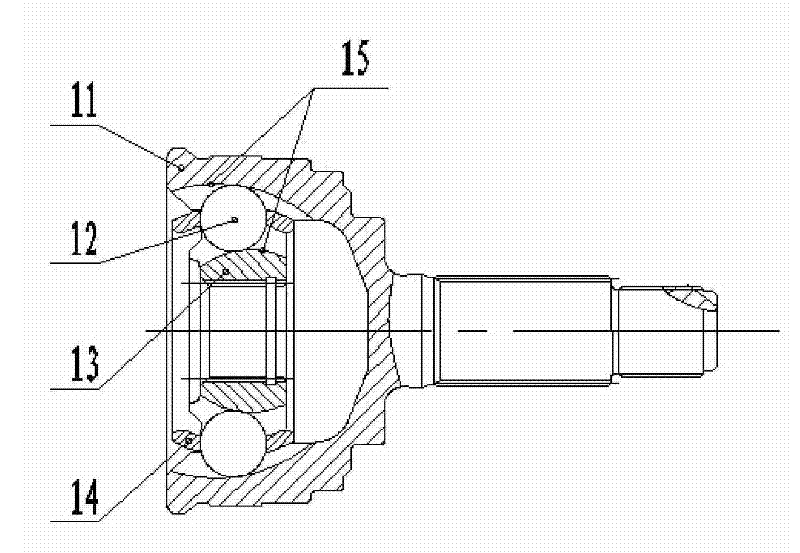

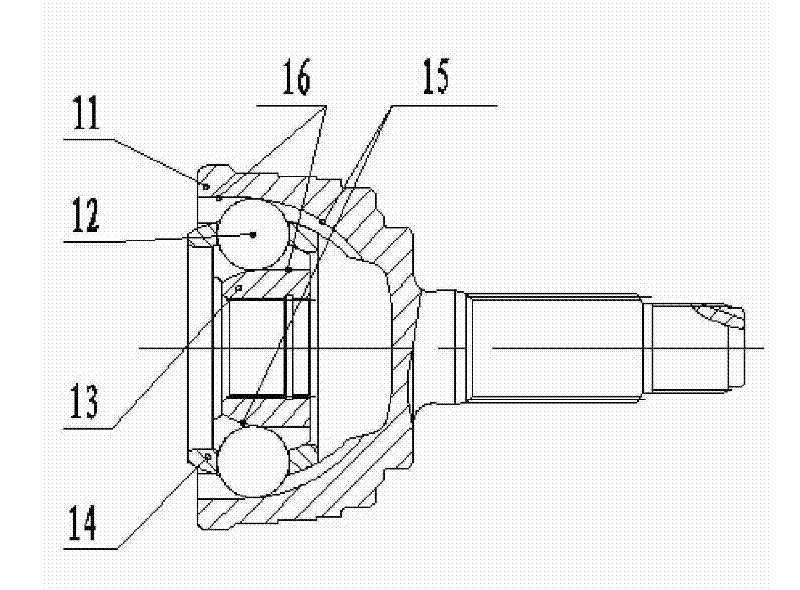

[0055] See Figure 6 , Figure 6-1 and Figure 6-2 , the transmission shaft of the present invention has a center-fixed constant velocity universal joint 10 at the drive wheel end, a center-fixed constant velocity universal joint 20 at the gearbox end, and an intermediate shaft 30. The intermediate shaft includes an intermediate shaft sleeve 31, an intermediate shaft core 33, a retaining Frame 34 and rolling element 32. In this embodiment, rolling element 32 is a steel ball. The mating surface of the intermediate bushing and the intermediate shaft core is a circumferential surface. Corresponding channels for accommodating steel balls are respectively provided. The shape can be a double arc or a single arc, and the cage is used to fix the relative position of the steel balls to ensure the rolling of the steel balls and the transmission of torque.

[0056] Such as Figure 6-1 and Figure 6-2 As shown, the outer diameter of the intermediate shaft sleeve is D1, the outer diame...

Embodiment 2

[0068] The intermediate shaft of the present invention can also adopt another structure, that is, the inner cavity of the intermediate shaft sleeve 31 and the outer shape of the intermediate shaft core 33 are regular polygons, the rolling element 32 adopts a needle roller type, and the corresponding cage 34 is also a regular polygon. The transmission of torque is completed by the corners of the cage.

[0069] The intermediate shaft sleeve, intermediate shaft core and needle roller are installed with a small interference fit, and the outer surface of the intermediate shaft core and the inner surface of the intermediate shaft sleeve are lubricated with grease, which can also ensure the telescopic function of the intermediate shaft, and because the contact surface of the needle roller is large , Strong wear resistance during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com