Atomic force microscope probe based on structures of carbon nano tube and planar wave guide

An atomic force microscope and planar waveguide technology, applied in waveguide, waveguide-type devices, scanning probe technology, etc., can solve problems such as large needle tip diameter, lack of high-frequency characteristics, and unsatisfactory mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

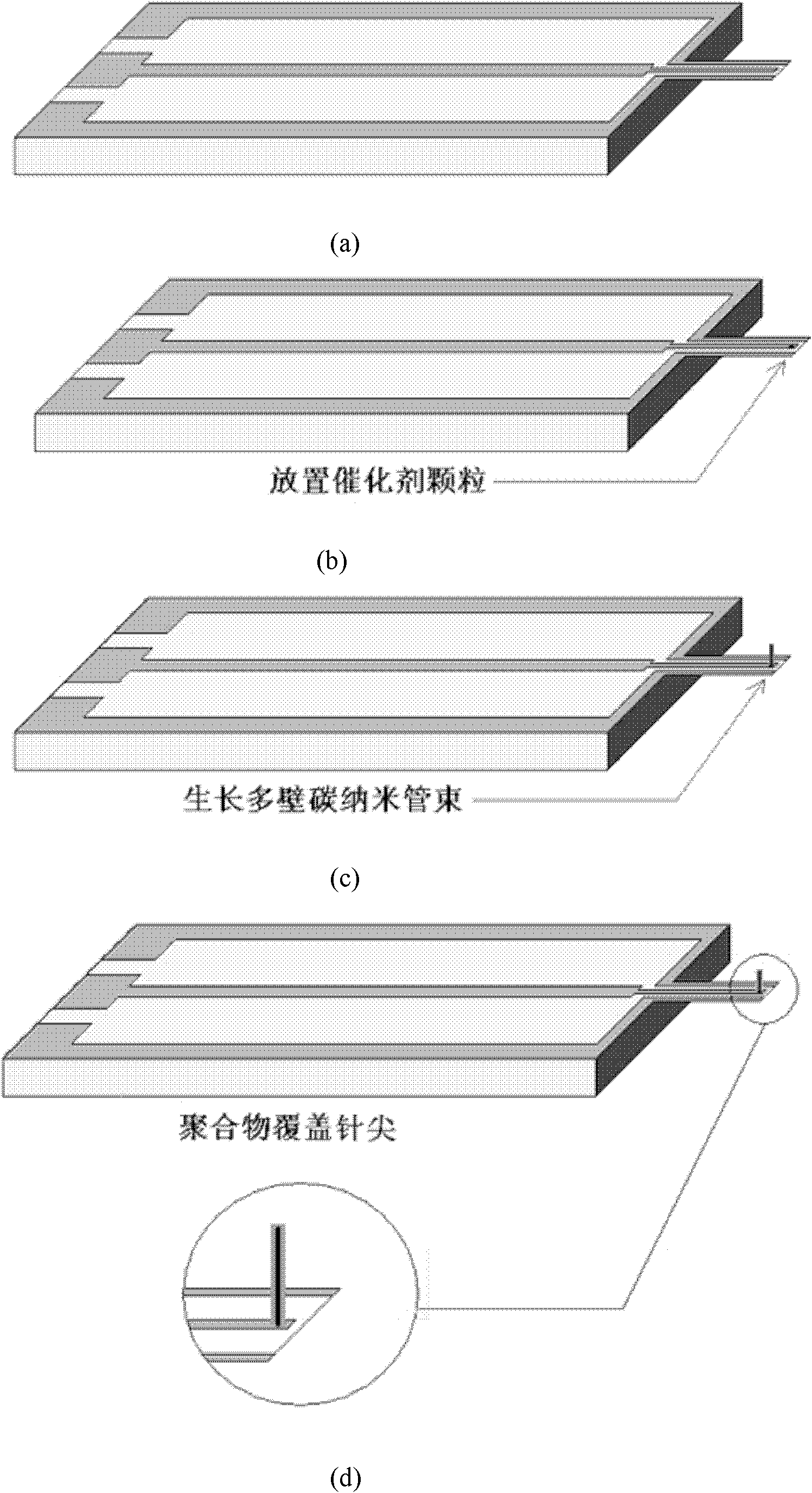

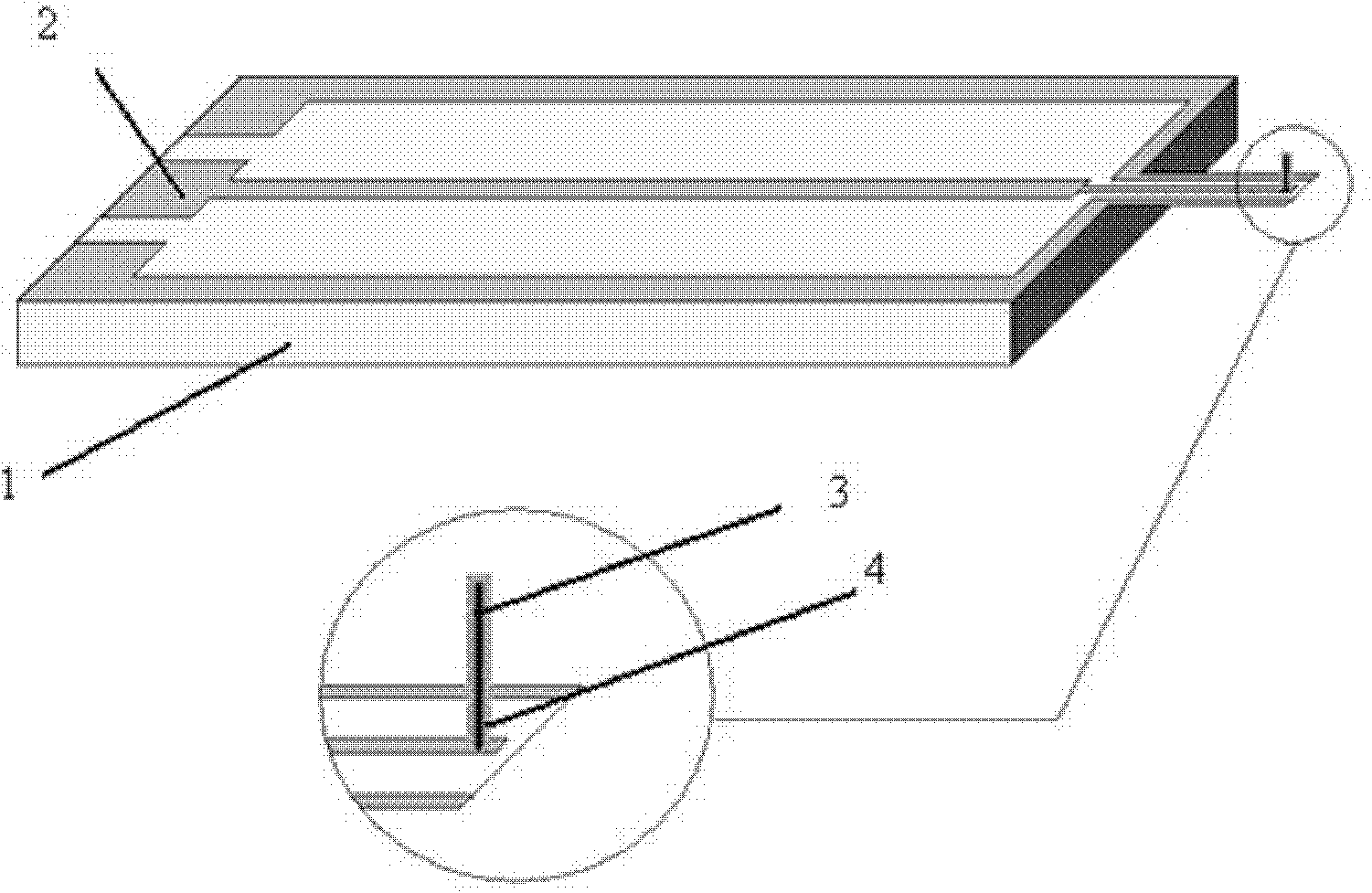

[0016] Embodiments of the present invention are described in more detail below with reference to the accompanying drawings of the present invention.

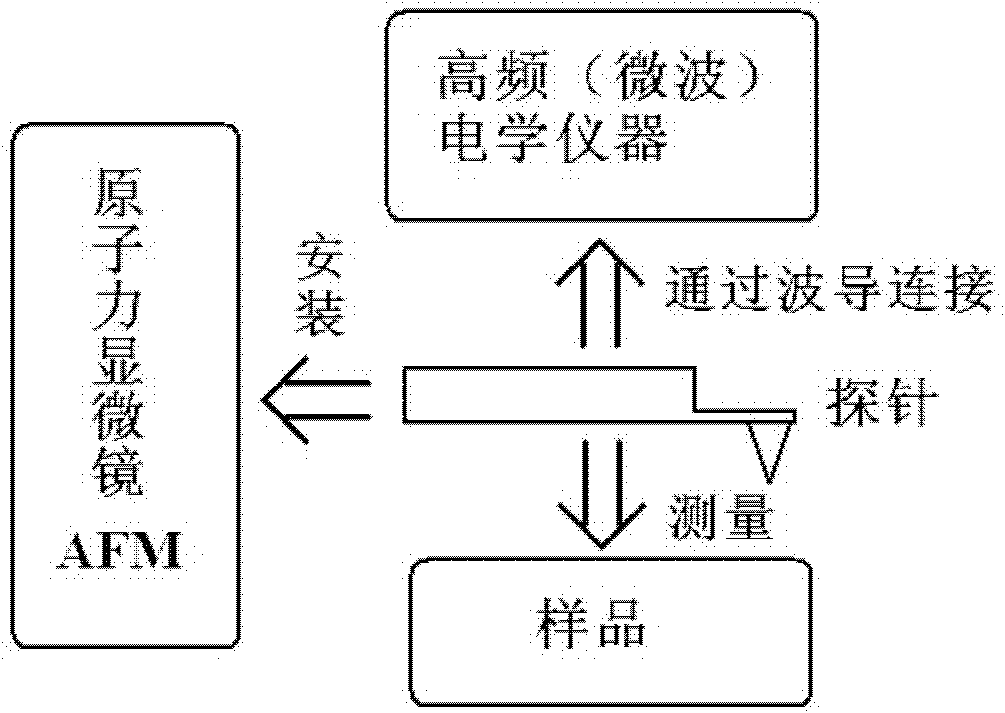

[0017] The invention provides an AFM probe that is relatively easy to prepare and can simultaneously measure surface morphology, high-frequency (to microwave band) electrical properties, etc. of samples such as nanomaterials, devices, and various soft substances. The device can accurately measure the surface topography of a sample by being installed to and operated by the AFM, and simultaneously measure the high-frequency characteristics of the sample in situ. The probe device can, but is not limited to, separately measure surface topography and high-frequency electrical properties. The characteristics of the carbon nanotubes at the needle tip can be controlled, but not limited to, by controlling the growth conditions and subsequent polymer encapsulation treatment. The probe setup allows multiple measurements to be made by chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com