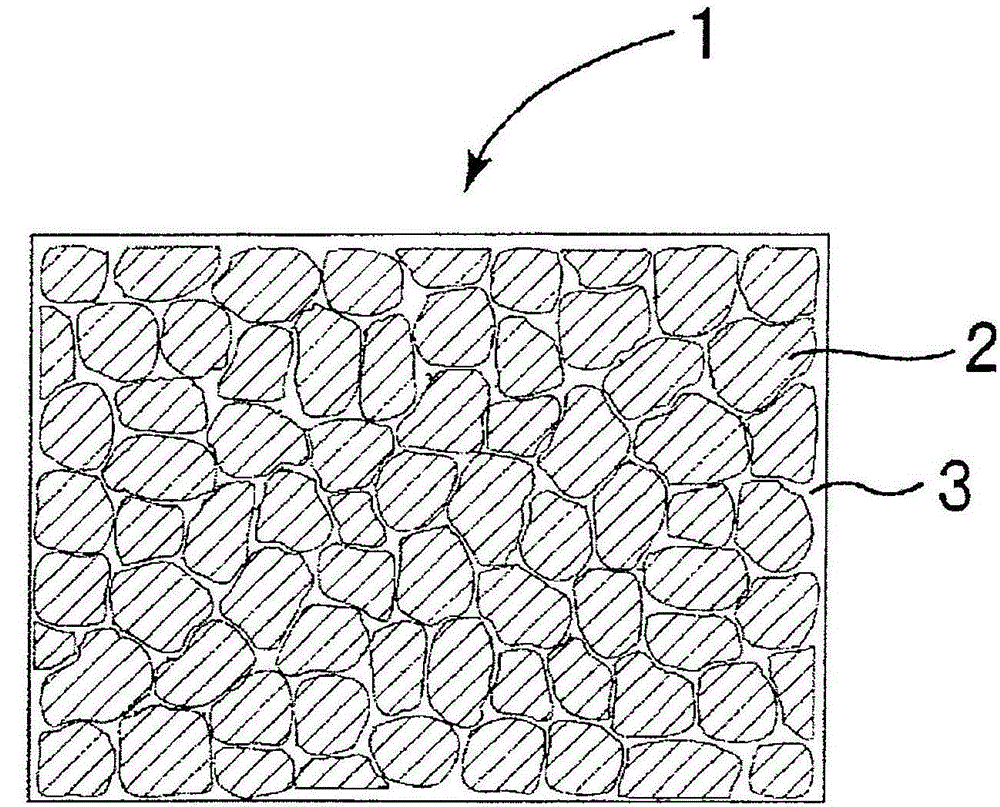

Method for controlling characteristics of ceramic carbon composite, and ceramic carbon composite

A control method and carbon composite technology, applied in the direction of graphite, etc., can solve the problems of limited freedom of manufacturing process, control of properties of difficult composite materials, etc., and achieve the effect of easy control of properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Artificial graphite particles (manufactured by Toyo Tanso Co., Ltd., mesophase graphite, particle size distribution (d10-d90) 15-20 μm, degree of graphitization 67%) 10 g, aluminum nitride powder (particle size distribution (d10 ~d90) 1~5μm) 3.55g and Y as a sintering aid 2 o 3 (0.19g) were mixed, and the mixed powder was prepared by dissolving acrylamide (8g) and N,N'-methylenebisacrylamide (1g) in isopropanol (45g) by the gel casting method The binder solution (2.84 g) was mixed and the mixture was cast in plastic moulds. The volume ratio of carbonaceous material and ceramics in the mixture is 80:20. The obtained mixture was dried at 80° C. for 12 hours under normal pressure to obtain a molded body. Next, a pressure of 30 MPa was applied to the molded body by spark plasma sintering under vacuum, and pulse energization sintering was performed under vacuum conditions at 2000° C. for 5 minutes, thereby obtaining a ceramic carbon composite material A.

Embodiment 2

[0064] As the carbonaceous material, artificial graphite particles (manufactured by Toyo Tanso Co., Ltd., machining residue, particle size distribution (d10-d90) 2-100 μm, degree of graphitization 83%) were used, except that, the same operation as in Example 1 , to obtain ceramic carbon composite material B.

Embodiment 3

[0066] As the carbonaceous material, use artificial graphite particles (manufactured by Toyo Tanso Co., Ltd., graphite material pulverized powder, aspect ratio 3.5, graphitization degree 98%), except that, operate in the same manner as in Example 1 to obtain ceramic carbon composite material C .

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com