Three-dimensional labeling method for part processing

A technology of 3D labeling and parts processing, which is applied in the field of parts processing, can solve problems such as unintuitive two-dimensional representation, non-unique data source, interruption of data information, etc., to reduce a lot of repetitive work, more intuitive two-dimensional functions, and two-dimensional functions Dimensional comparison is more effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

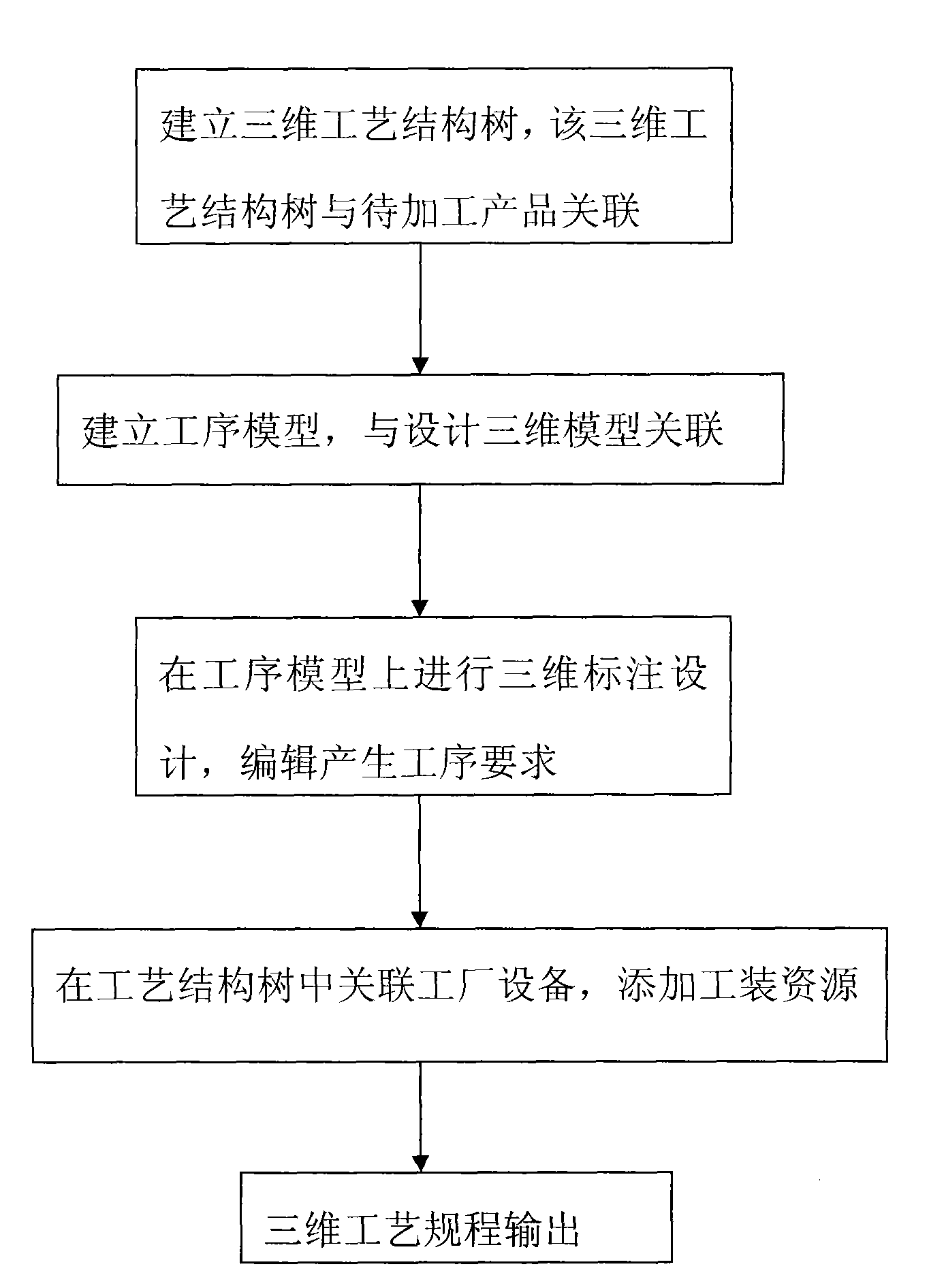

[0087] see figure 1 The method for obtaining three-dimensional processing parts involved in the present invention comprises the following steps:

[0088] 1) Establish a three-dimensional process structure tree, which is associated with the product to be processed, the processing unit and the equipment;

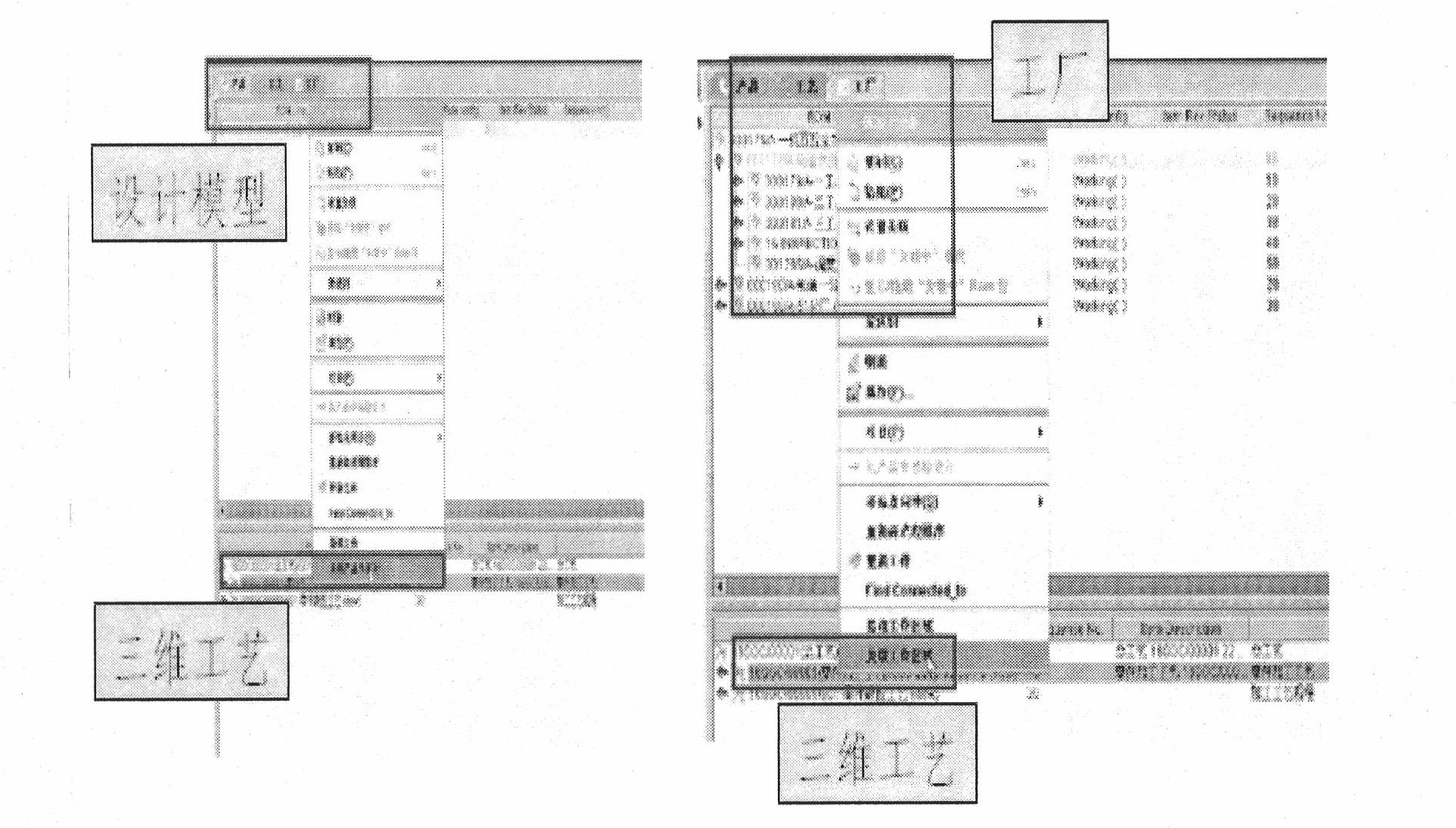

[0089] 2) Establish a process model and associate it with the design 3D model;

[0090] 3) Carry out three-dimensional annotation design on the process model, edit and generate process requirements;

[0091] 4) Add tooling resources in the craft structure tree;

[0092] 5) Three-dimensional process specification output.

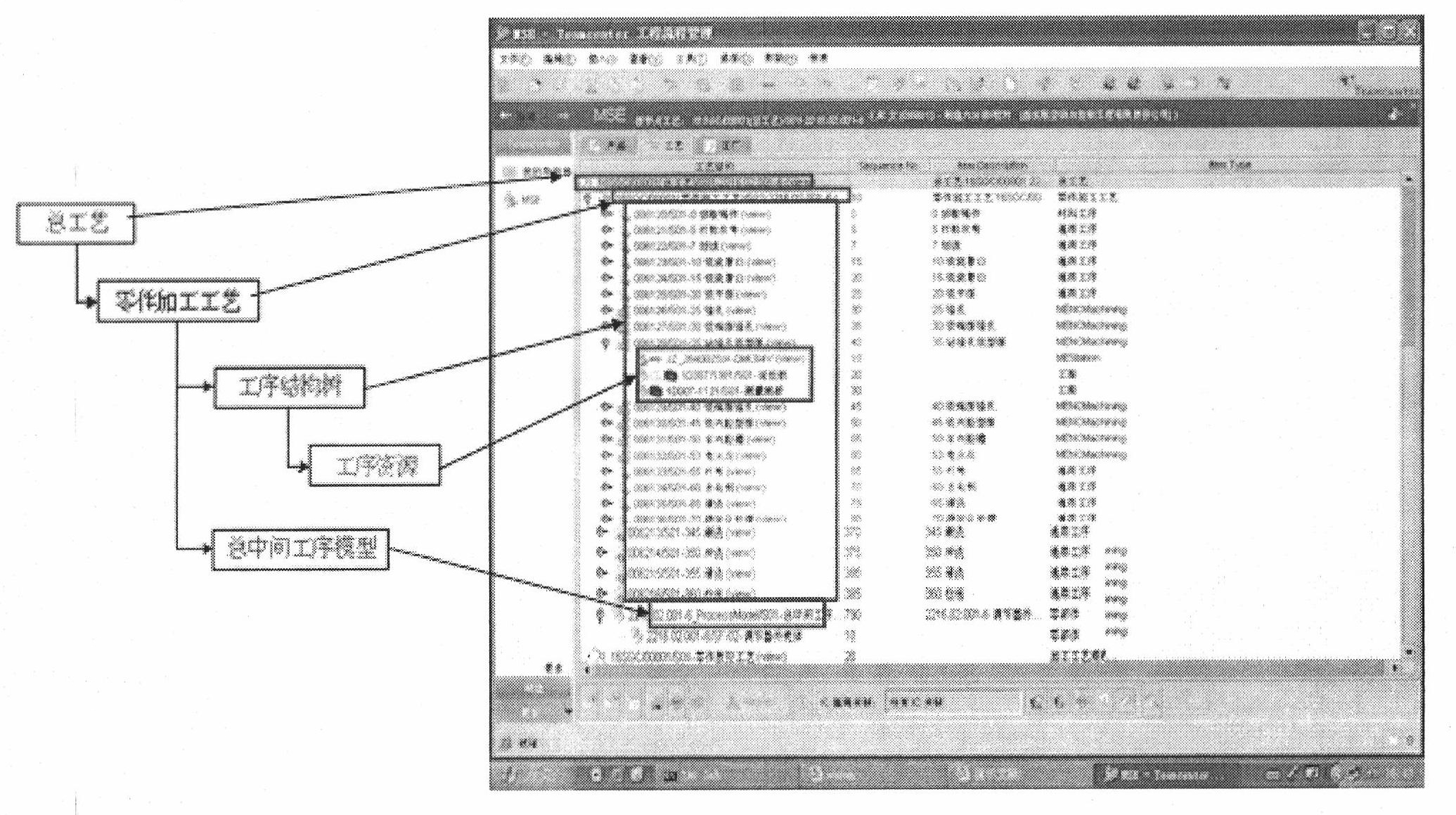

[0093] see figure 2 , 3 , 4, 5, 6, 7, 8, 9, 10, 11, 12, the three-dimensional process structure tree in step 1) in the method includes the total process, the total process includes the component processing technology, and the component processing technology includes The process structure tree and the overall intermediate process model; the above proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com