Induction and phase-shifting rectifier transformer

A rectifier transformer, transformer technology, applied in the direction of transformer/inductor coil/winding/connection, preventing/reducing unwanted electrical/magnetic influence, etc. Effects of wave loss, harmonic loss reduction, and harmonic magnetic flux reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

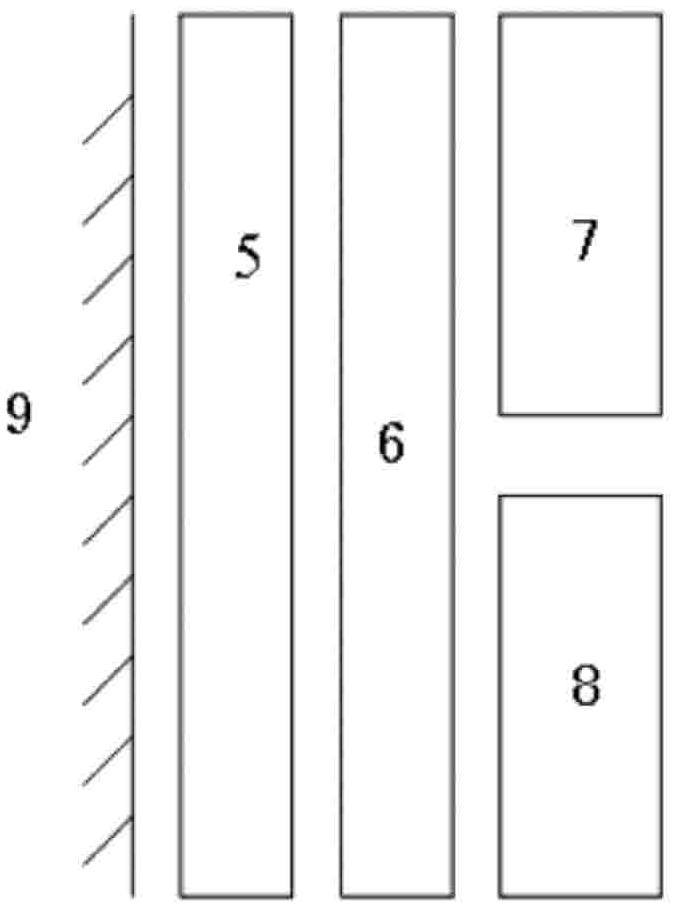

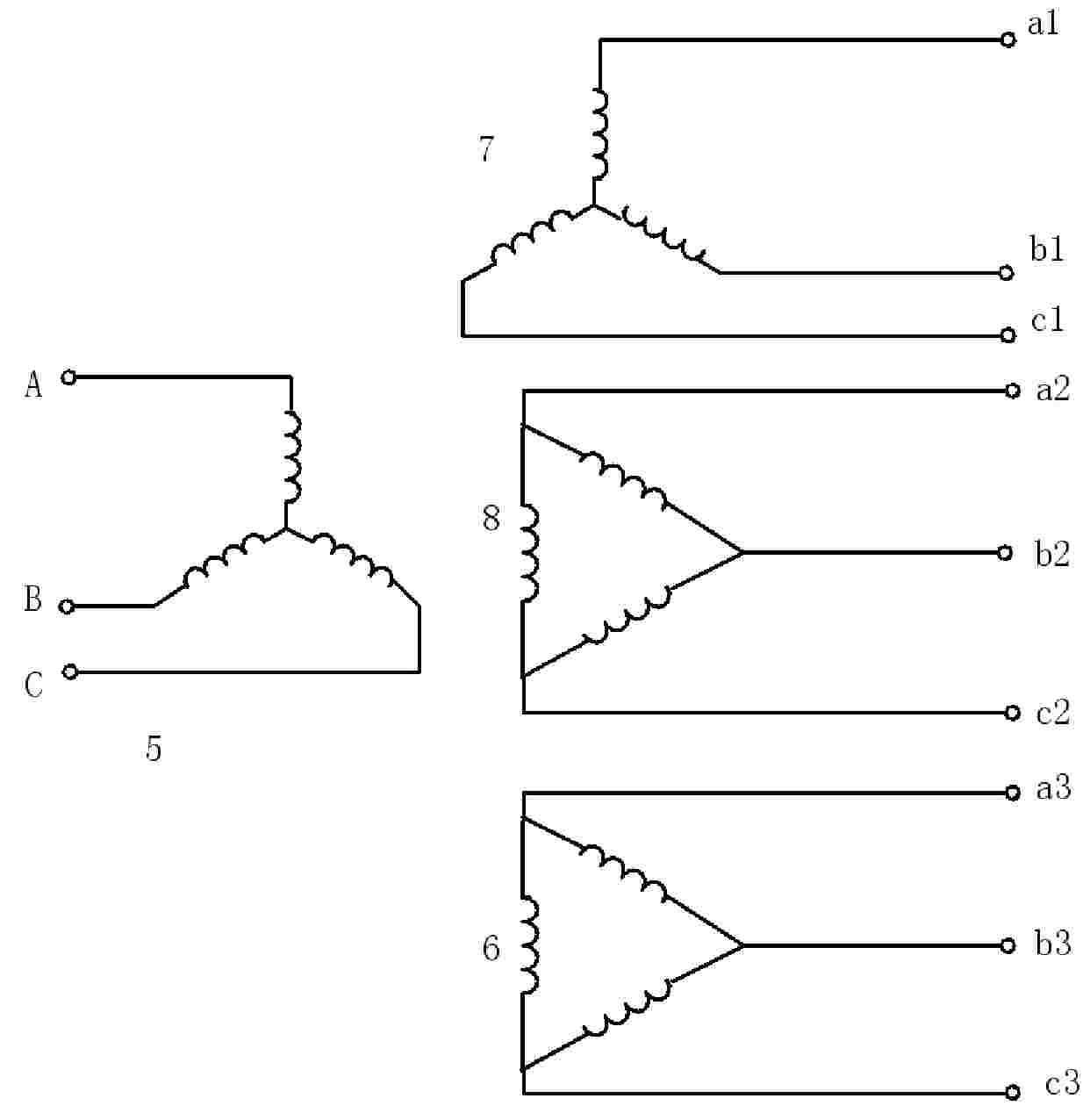

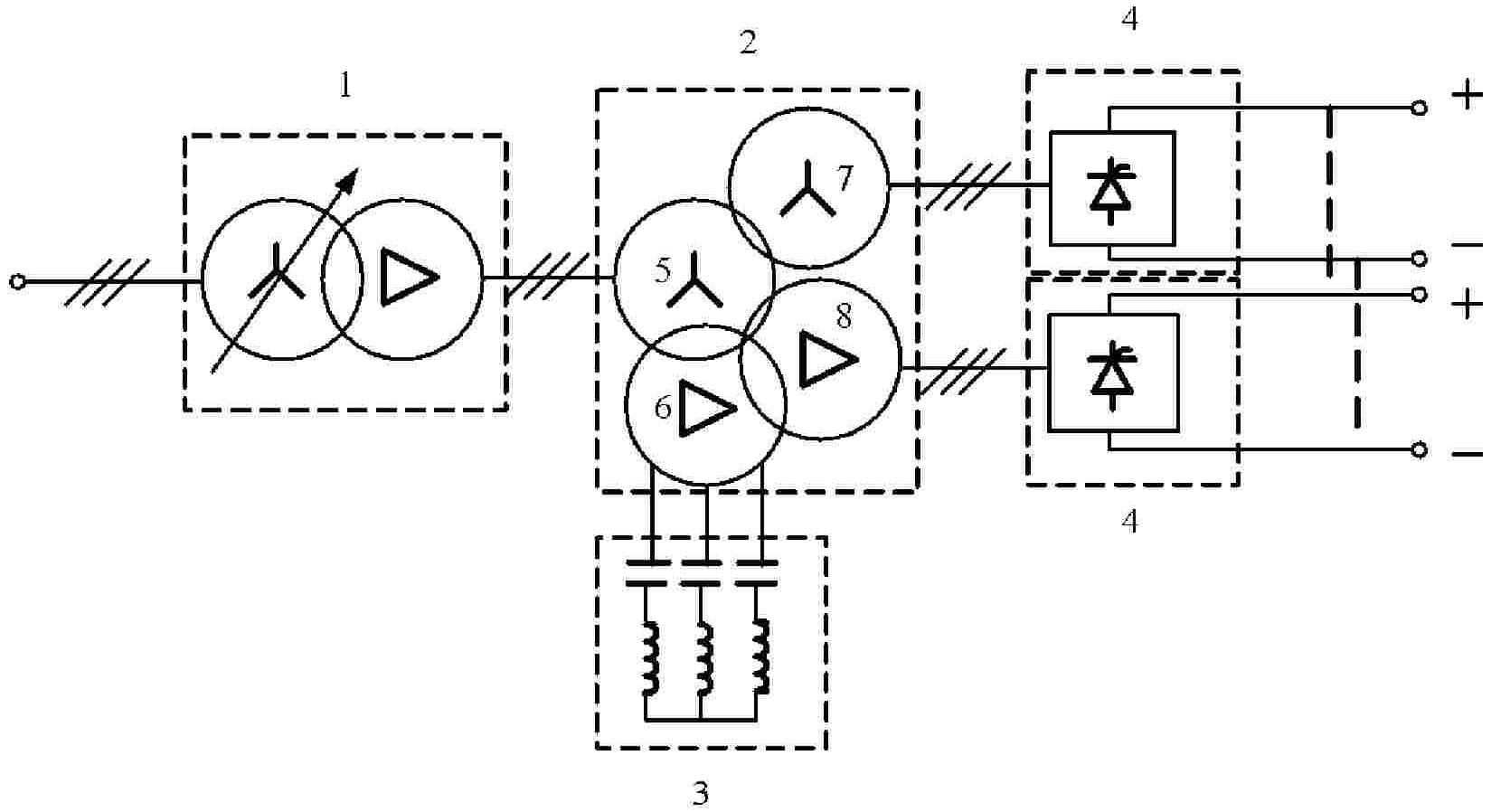

[0014] Such as figure 1 The induction and phase-shifting rectifier transformer 2 shown is a three-core column structure, and four windings are wound on each core column 9, which are the AC network side winding 5, the filter winding 6, and the valve side star connection winding 7. and delta connection winding 8; considering that the valve side of the rectifier transformer is mostly high current and low voltage, in order to facilitate heat dissipation; therefore, the grid side winding 5 is wound on the innermost layer, closest to the core; the filter winding 6 is wound on the grid side winding The outer layer of the outer layer; the star connection winding 7 and the delta connection winding 8 on the valve side are wound on the outer layer of the filter winding 6, and both adopt the same direction antiparallel winding method. The grid side winding 5 is connected to the voltage regulating transformer 1, the three-phase terminal leads of the filter winding 6 are connected to the 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com