Axle linkage assembly for a commercial vehicle and method for producing said axle linkage assembly

A technology of linkage between commercial vehicles and axles, applied in the directions of axles, vehicle springs, vehicle components, etc., can solve the problems of cost and inapplicability of axle linkages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

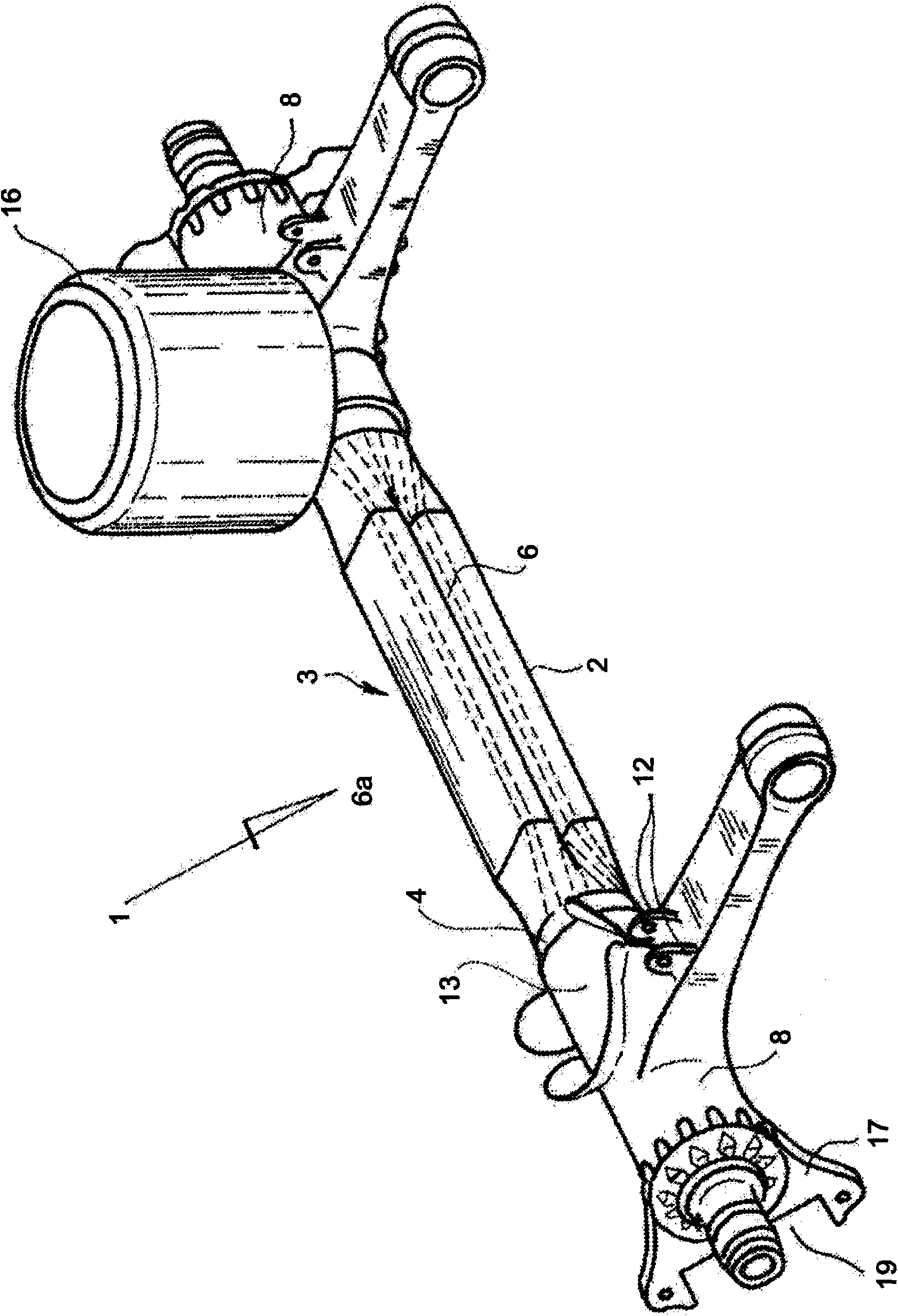

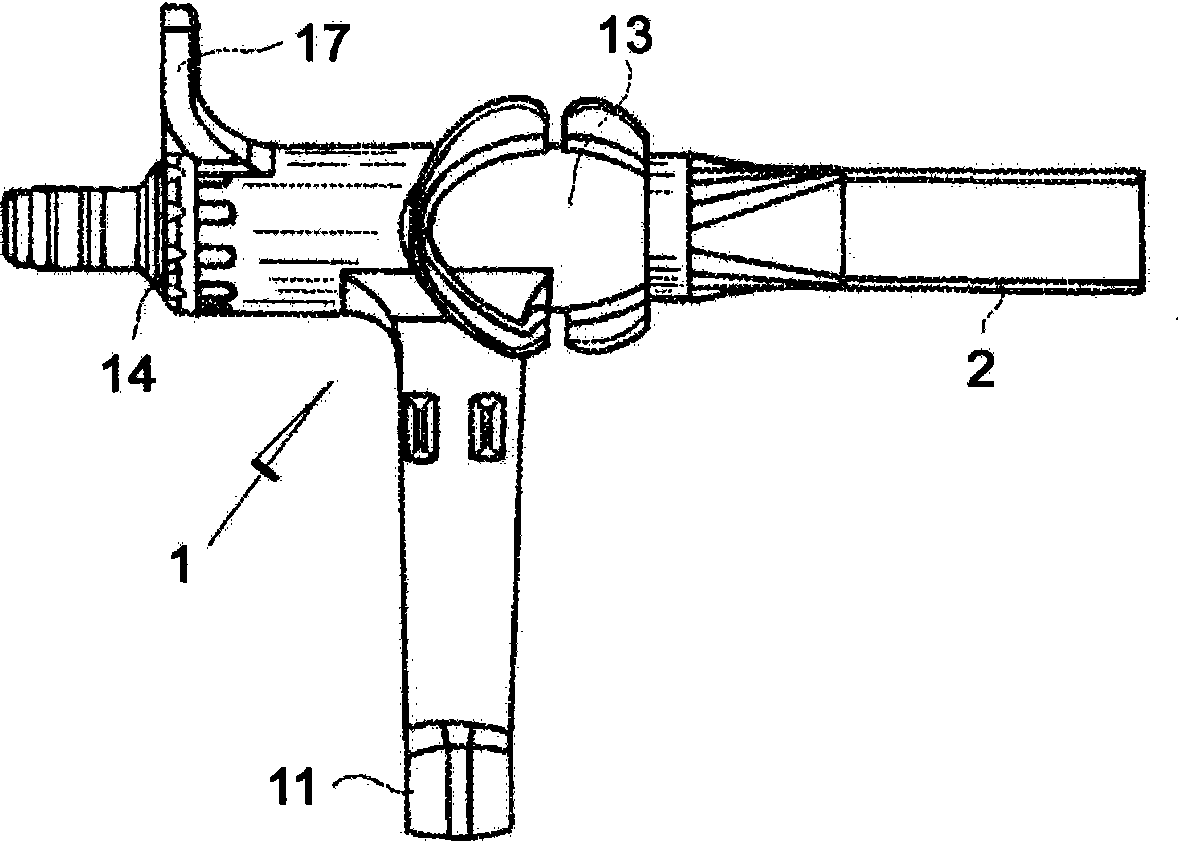

[0123] Figure 1 to Figure 3 Shaft linkage shown in 1 and Figures 5 to 8d The axle linkages 101 shown are in each case part of a non-drive axle of a trailer, not shown here, which is used to tow a load vehicle, likewise not shown.

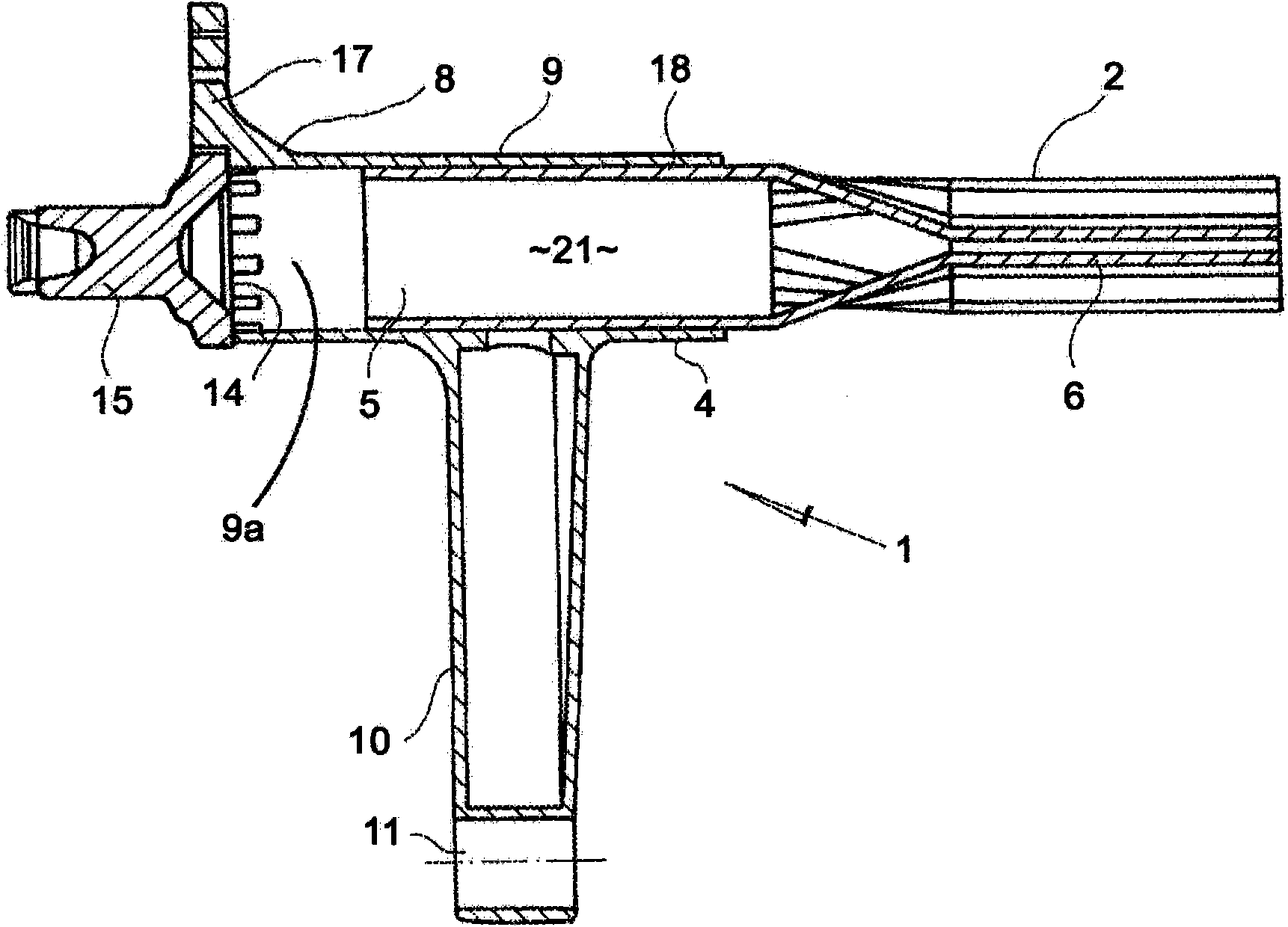

[0124] The shaft drive 1 here comprises a shaft 2 formed as a shaft profile, which can be provided in a tubular configuration. At each end of the shaft 2 a longitudinal drive rod 8 is provided.

[0125] The shaft 2 is made of a hollow sheet steel profile and terminates in two couplings 4 on the end faces, one of which is in the figure 2 shown in . The end-side coupling 4 has a design in the form of a hollow profile 5 which is open toward its free end.

[0126] The shaft 2 , which runs from one side of the motor vehicle to the other, has an approximately square cross-section in its central region, unlike the coupling 4 , and is also provided with a pressed-in guide groove deformation 6 , so that a torsion Section 6 a , over which the torsiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com