Plastic sucking disc

A technology for blister trays and trays, applied in clothing, applications, jewelry, etc., can solve problems such as product quality management difficulties, large amount of tooling and drill boards, and workshop environmental management difficulties, so as to reduce manual operations and streamline processing procedures , Reduce the difficulty of workshop management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for surface plating of rhinestones, the steps are as follows:

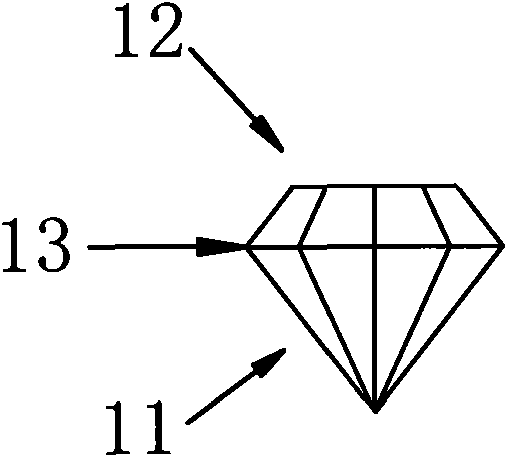

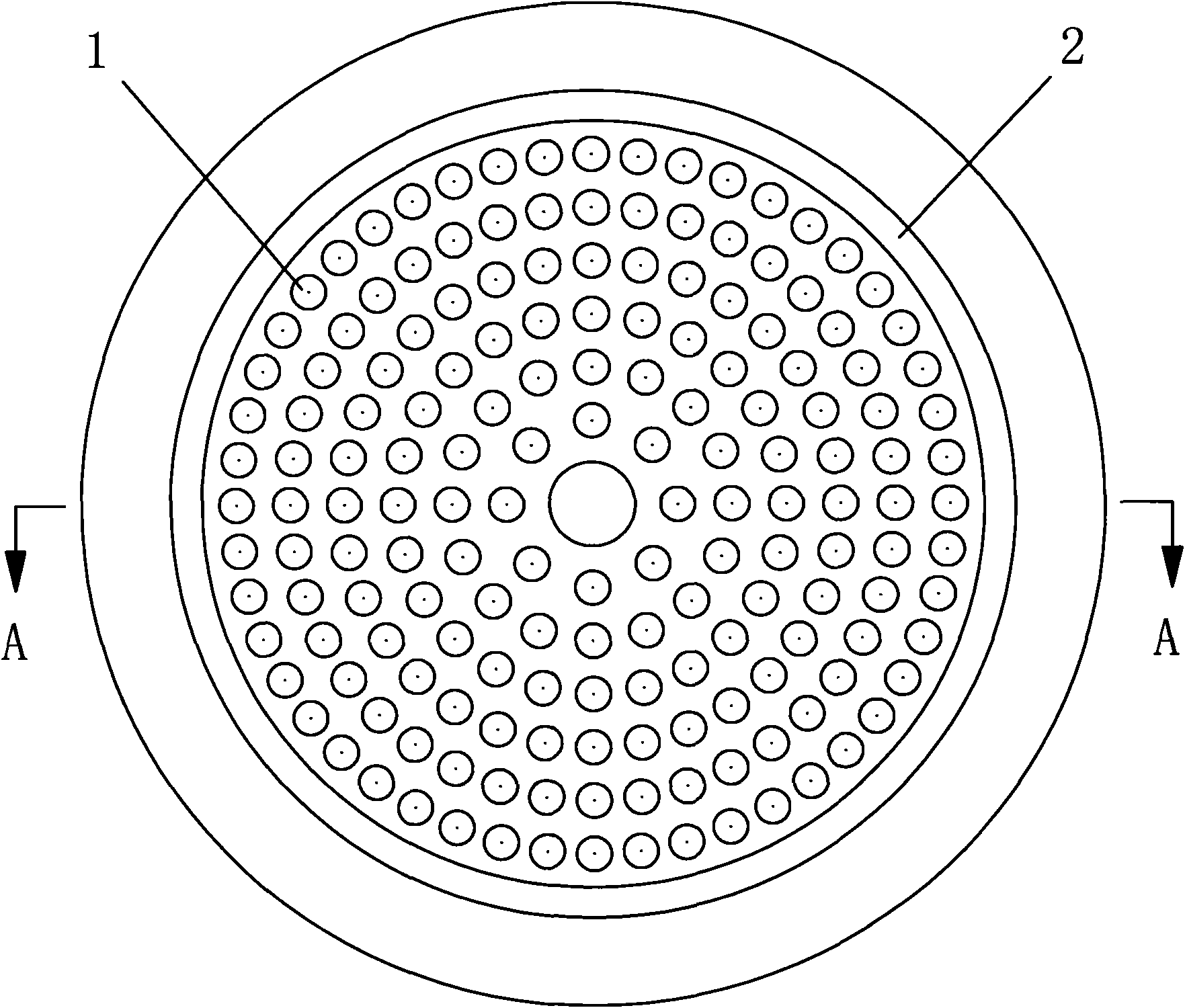

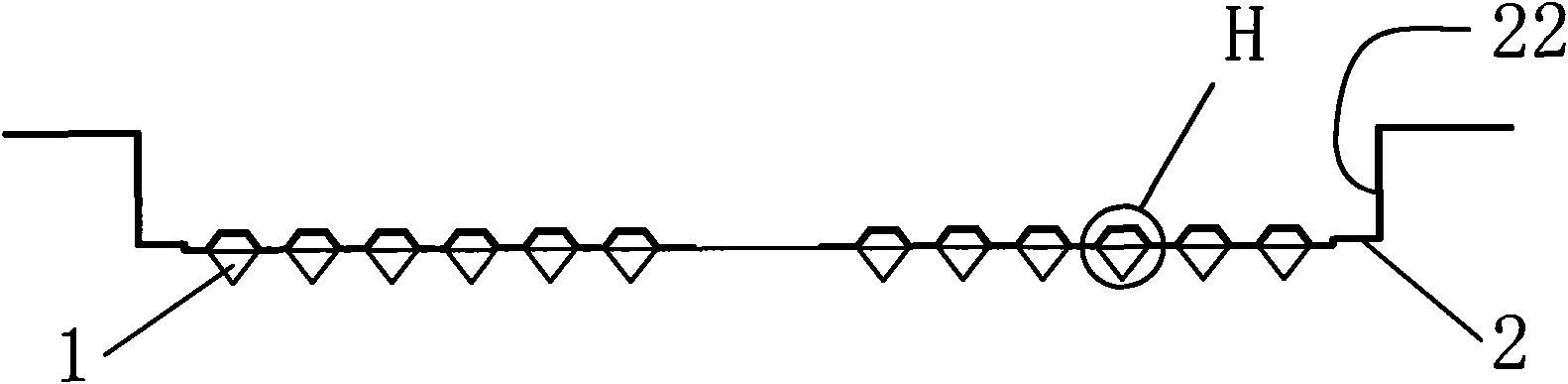

[0046] 1) Arrange multiple rhinestones 1 in a consistent direction and blister them into a blister tray 2, such as Figure 2~4 As shown, one surface of the blister tray 2 is formed with a plurality of suction holes 21 matching the face of the rhinestone 1, and the face of the rhinestone 1 is embedded in the suction hole 21 and fixed;

[0047] 2) Plating a reflective layer 14 on one side of the blister plate 2 with rhinestones 1, and the reflective layer 14 is a silver layer;

[0048] 3) Coating a protective layer 15 on the side of the blister plate 2 coated with the reflective layer 14, the protective layer 15 being an anti-tarnish paint layer;

[0049] 4) Separate the rhinestone 1 from the blister 2 and take it out.

[0050] In this embodiment, in the above step 1, a plurality of rhinestones 1 are first arranged on the plate surface of the tooling plate A4 through the bottom of the vibrating cloth device, ...

Embodiment 2

[0053] A method for surface plating of rhinestones, the steps are as follows:

[0054] 1) A plurality of rhinestones 1 are arranged in a consistent direction and formed into a blister tray 2 by blister molding. A plurality of suction holes 21 are formed on one surface of the blister tray 2 to match the face of the rhinestone 1; The face of the rhinestone 1 is embedded in the suction hole 21 and fixed;

[0055] 2) Plating a reflective layer 14 on one side of the blister plate 2 with rhinestones 1, the reflective layer 14 being an aluminum layer or a chromium layer;

[0056] 3) Coating a protective layer 15 on the side of the blister disc 2 where the reflective layer 14 is plated, and the protective layer 15 is a copper layer or a copper-zinc alloy layer;

[0057] 4) Separate the rhinestone 1 from the blister 2 and take it out.

[0058] In this embodiment, the blister plate used in the end face grinding and polishing is used, that is, the end face grinding and polishing process adopts th...

Embodiment 3

[0060] Such as Picture 9 , Picture 10 , Picture 11 A blister tray is shown. A surface of the blister tray 2 is provided with a plurality of suction holes 21 that match the face of the rhinestone 1, in which the rhinestone 1 is embedded, and the face of the rhinestone 1 is embedded The suction hole 21 is inside and fixed; the surface of the blister plate 2 inlaid with the rhinestone 1 is plated with a reflective layer, and the reflective layer is a silver layer, an aluminum layer or a chromium layer. The outer surface of the reflective layer is coated with a protective layer, and the protective layer is an anti-tarnish paint layer, a copper layer or a copper-zinc alloy layer. The junction 13 between the face and the bottom of the rhinestone 1 is embedded in the suction hole 21 of the blister disc 2 by 0.05-0.2 mm (that is, the plastic layer of the blister completely covers the junction between the face and the bottom of the rhinestone 1 and extends downward to cover 0.05~0.2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com