Method for extrusion molding of lead-free specially shaped copper tubes

An extrusion molding and copper tube technology, applied in the field of lead-free special-shaped copper tube extrusion, can solve the problems of high cost, long cycle, complicated process, etc., and achieve the production cost reduction, production efficiency improvement, simple and efficient processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

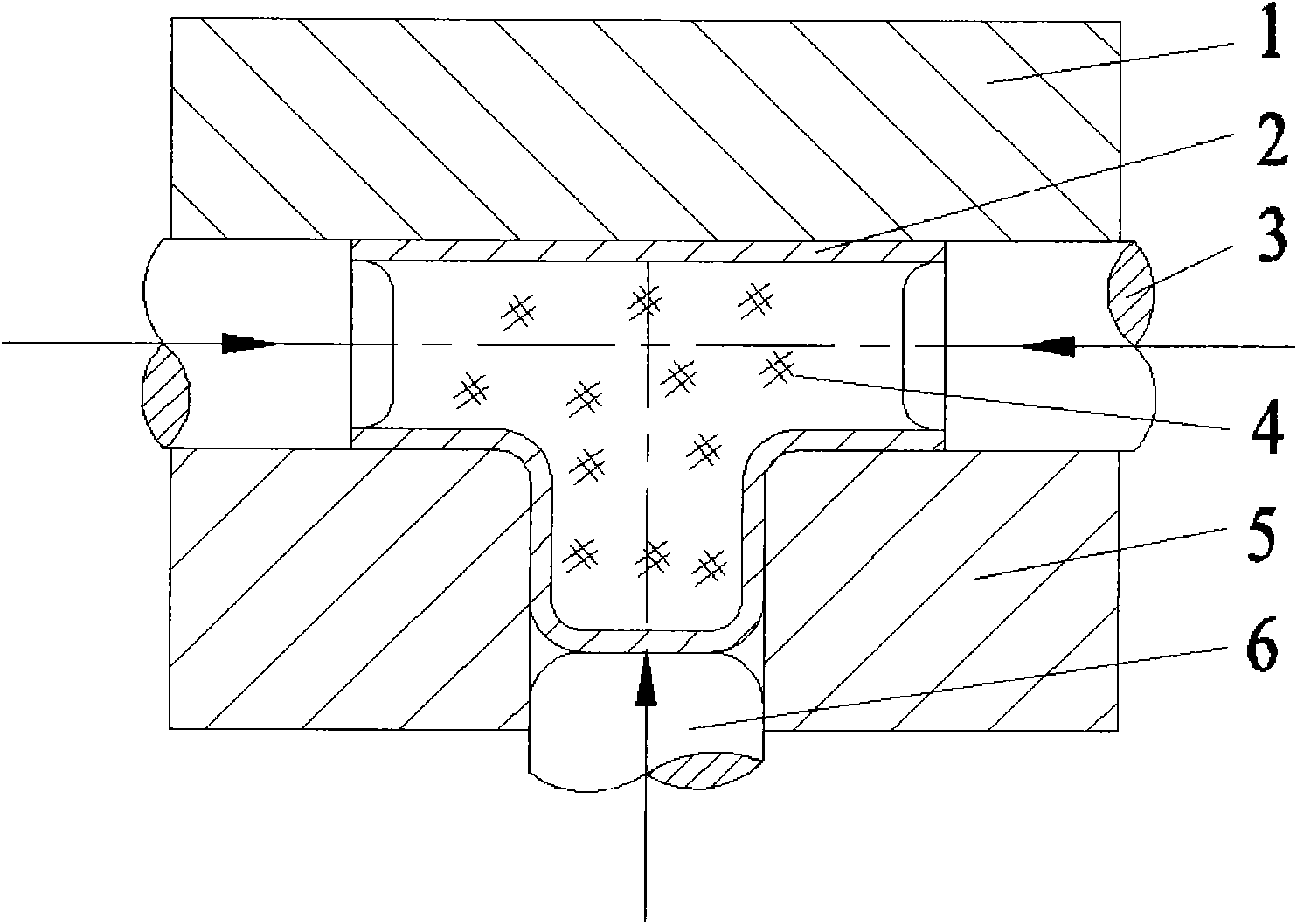

[0010] exist figure 1 Among them, a lead-free special-shaped copper tube extrusion molding structure consists of (1), upper half die (2), special-shaped copper tube blank (3), punch (4), extrusion medium (5), lower half Die (6), demoulding ejector pin. The extrusion medium (4) is composed of potassium nitrate, animal fat and calcium stearate mixed in a certain proportion.

[0011] When extruding lead-free special-shaped copper tubes, first mix potassium nitrate, animal fat and calcium stearate uniformly in a certain proportion; put the mixture of potassium nitrate, animal fat and calcium stearate into and fill the copper tube Blank, forming a copper tube filled with the extrusion mixture medium; put the copper tube blank into the extrusion die, and pass a collecting valve in the extrusion machine to make the amount of oil distributed to the cylinders on both sides equal, and at the same time in the side cylinder circuit A one-way throttle valve is connected in series to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com