Precoated sand multi-stack casting process

A casting process, a technology of coated sand, which is used in the manufacture of spare parts in the automobile and machinery industries, and the multi-layered casting process of coated sand. Heavy labor and other problems, to achieve the effect of improving production efficiency, reducing labor, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

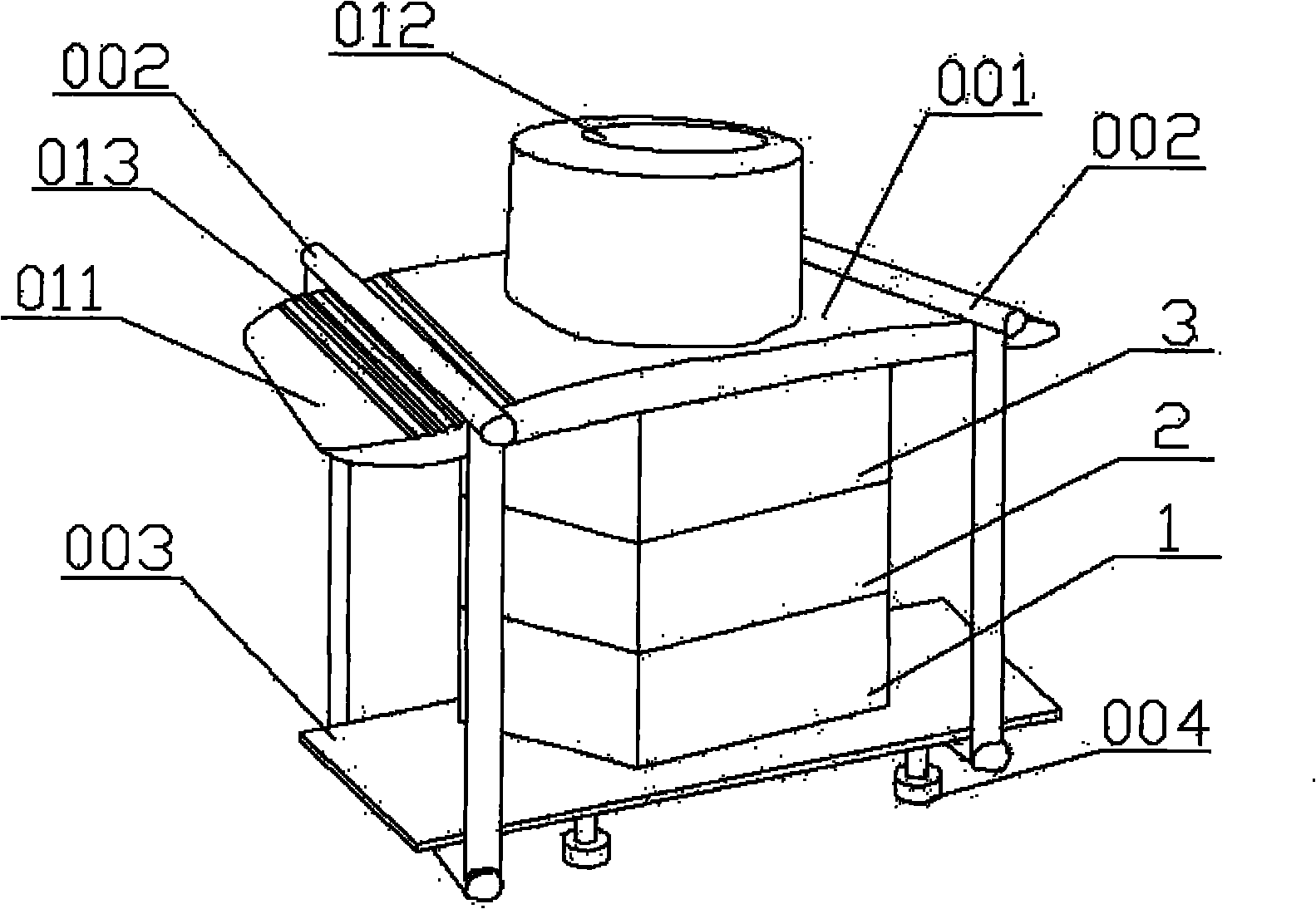

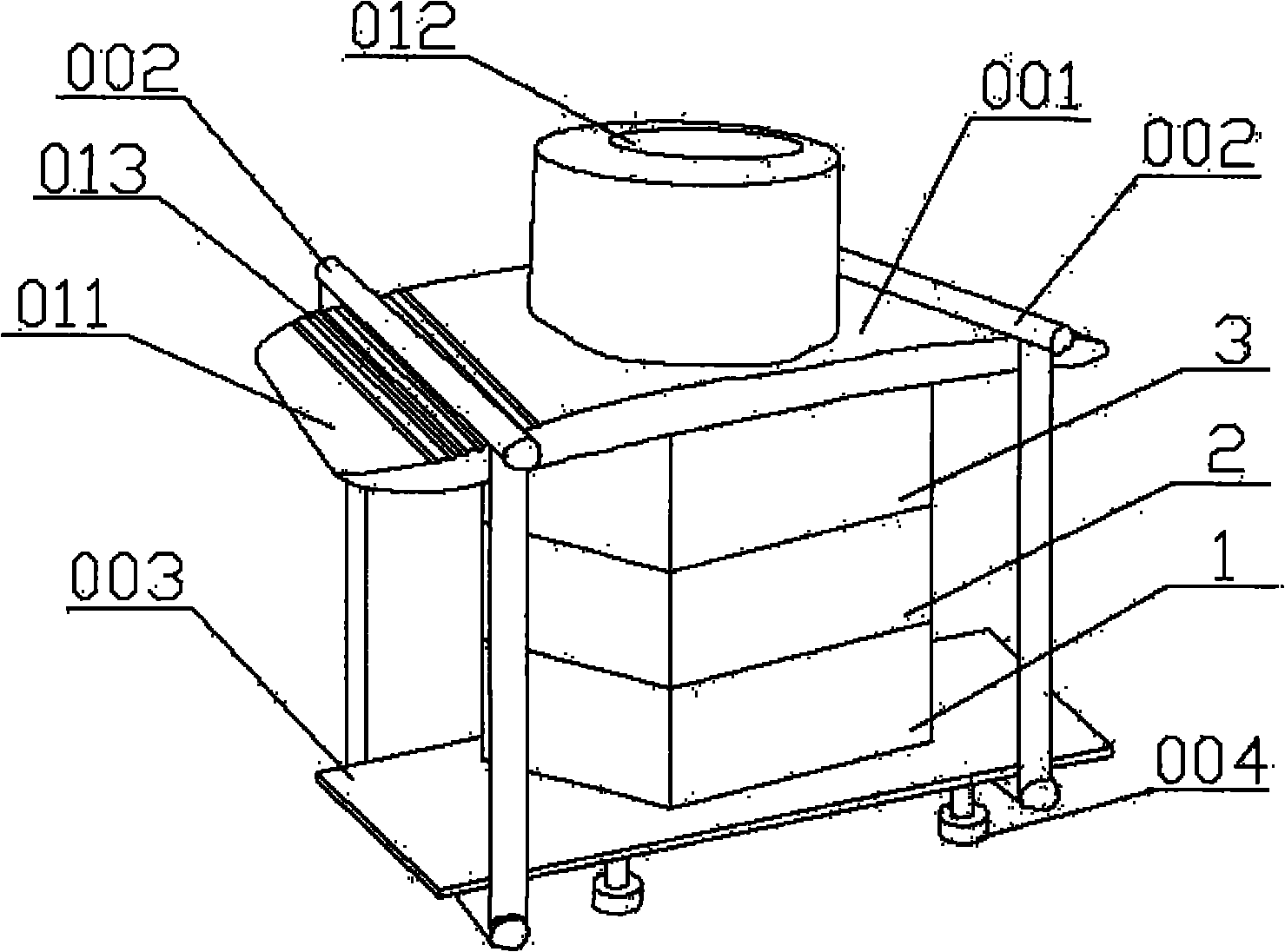

[0022] The multi-stack casting process of coated sand in this embodiment includes the following steps in turn:

[0023] a: Make the coated sand shell type unit according to the casting drawing. The middle part of the shell-type unit is provided with a sprue vertically penetrating through the coated sand shell-type unit; the casting cavity is distributed around the sprue and communicated with it through the runner. The surroundings of the sprue on the upper surface of the shell-type unit and the sprue on the lower surface can be respectively provided with grooves or bosses whose sizes are engaged with each other, so that the shell-type units are tightly connected when stacked to prevent the high-temperature liquid material from penetrating. leak. The shell-type unit is formed by clamping an upper mold and a lower mold, and the sand mold wall is thickened at the hot spot. The bottom of the shell-type unit is provided with a liquid storage tank which communicates with the casti...

Embodiment 2

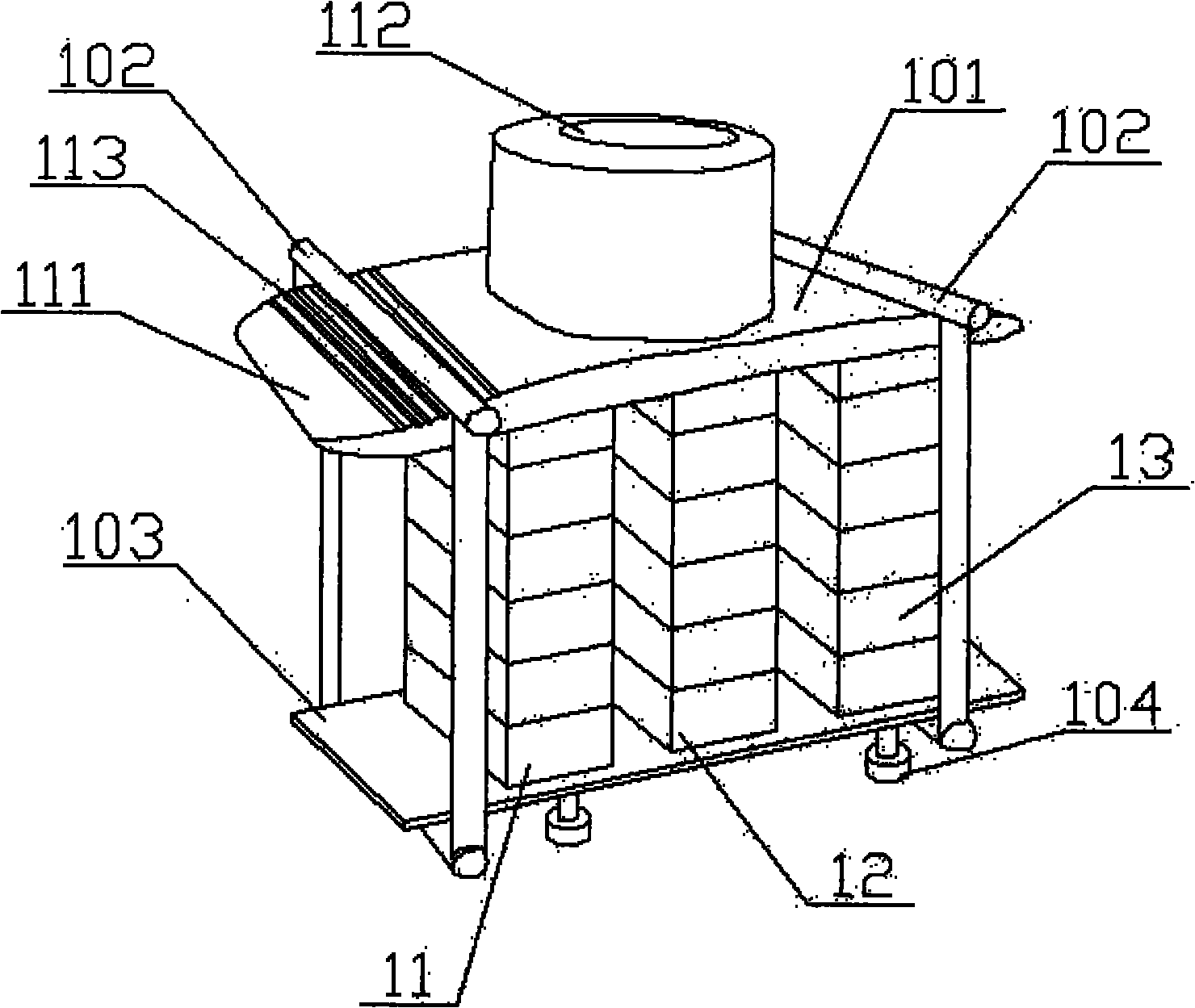

[0032] The multi-stack casting process of coated sand in this embodiment includes the following steps in turn:

[0033]a: Make the coated sand shell type unit according to the casting drawing. The middle part of the shell-type unit is provided with a sprue vertically penetrating through the coated sand shell-type unit; the casting cavity is distributed around the sprue and communicated with it through the runner. The shell-type unit is formed by clamping an upper mold and a lower mold, and the sand mold wall is thickened at the hot spot. The bottom of the shell-type unit is provided with a liquid storage tank which communicates with the casting cavity of the lower shell-type unit, and is used for feeding the high-temperature liquid material during cooling.

[0034] b: Six sets of shell-type units are stacked vertically to form a building, and a total of three shell-type units are placed on the iron base. The sprues of each shell-type unit in the same building are vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com