Water body suspended load silt and surface sediment integrated rapid collecting and separating device

A technology of surface sediment and separation device, which is applied in liquid separation, grease/oily substance/float removal device, cyclone device, etc. Safe to use, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

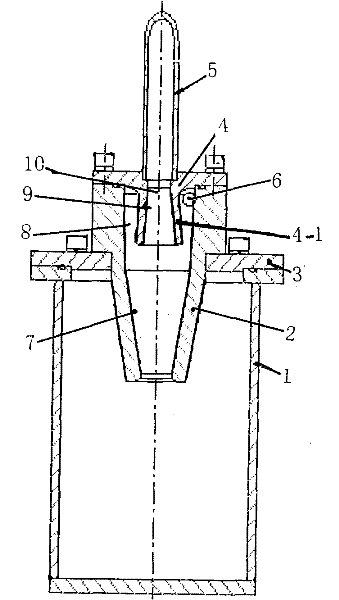

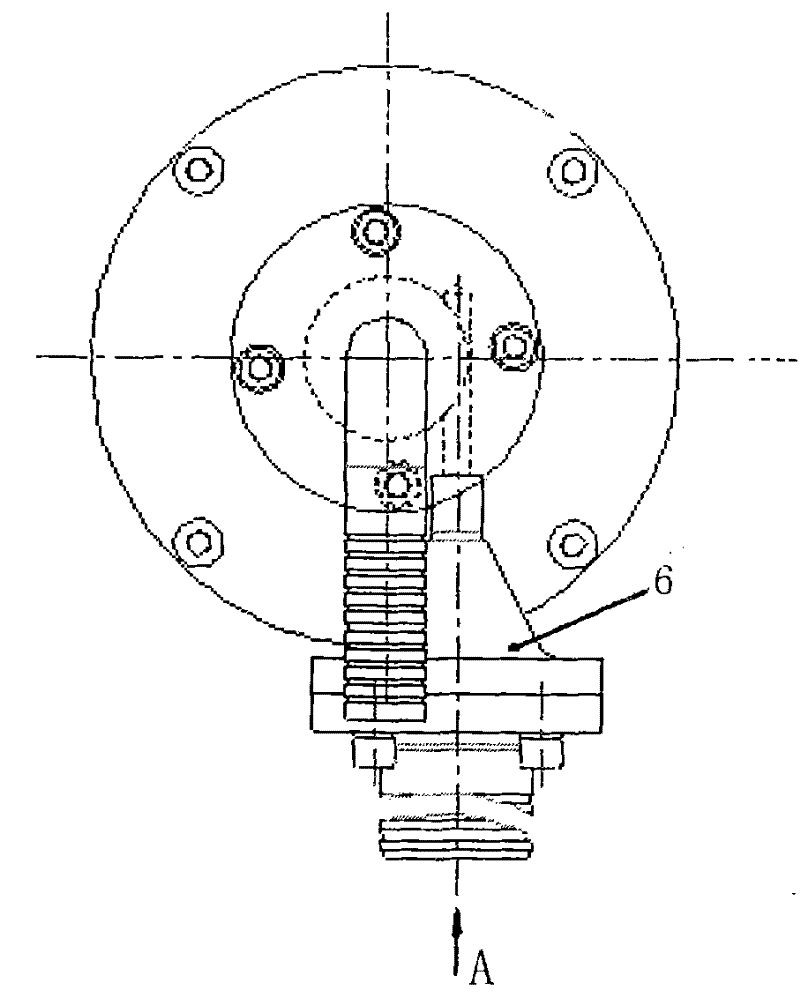

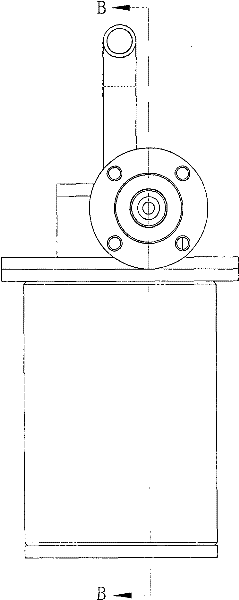

[0031] see Figure 1 to Figure 5 In this embodiment, the integrated rapid collection and separation device for suspended sediment and surface sediment in the water body includes a collector 1, a separator 3 that is sealed and connected to the top of the collector through a connecting screw and an O-ring, and a separator 3 that is connected to the top of the collector through a connecting screw and an O-shaped sealing ring. The O-ring seal is connected with the overflow guide cone 4 on the top of the separator, and the overflow pipe 5 is connected with the outlet of the overflow guide cone. The cone 2 in the separator protrudes into the collector. The separator is sequentially provided with a first inverted conical chamber 7 and a second inverted conical chamber 8 from bottom to top. The tapers of the first inverted conical cavity and the second inverted conical cavity are 16 degrees and 4 degrees respectively. One end of the pressure pipe 6 enters the separator from the tang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com