Electric regenerating device for inactive ion exchange resin

A technology for ion exchange resin and resin regeneration, applied in ion exchange regeneration, ion exchange, electric regeneration, etc., can solve the problems of complex device structure, inconvenient operation and use, etc., achieve good regeneration effect, prevent resin from failing again, and be convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

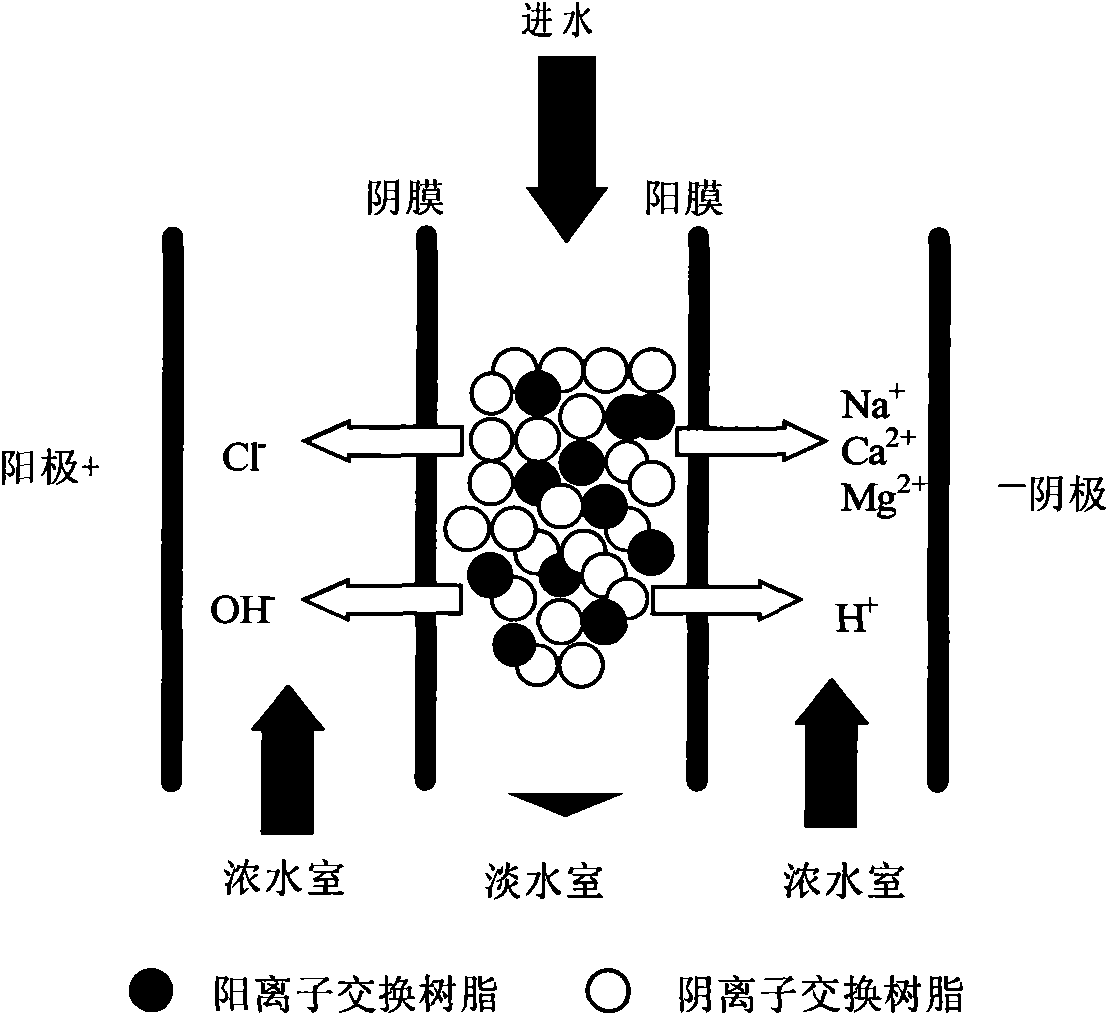

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

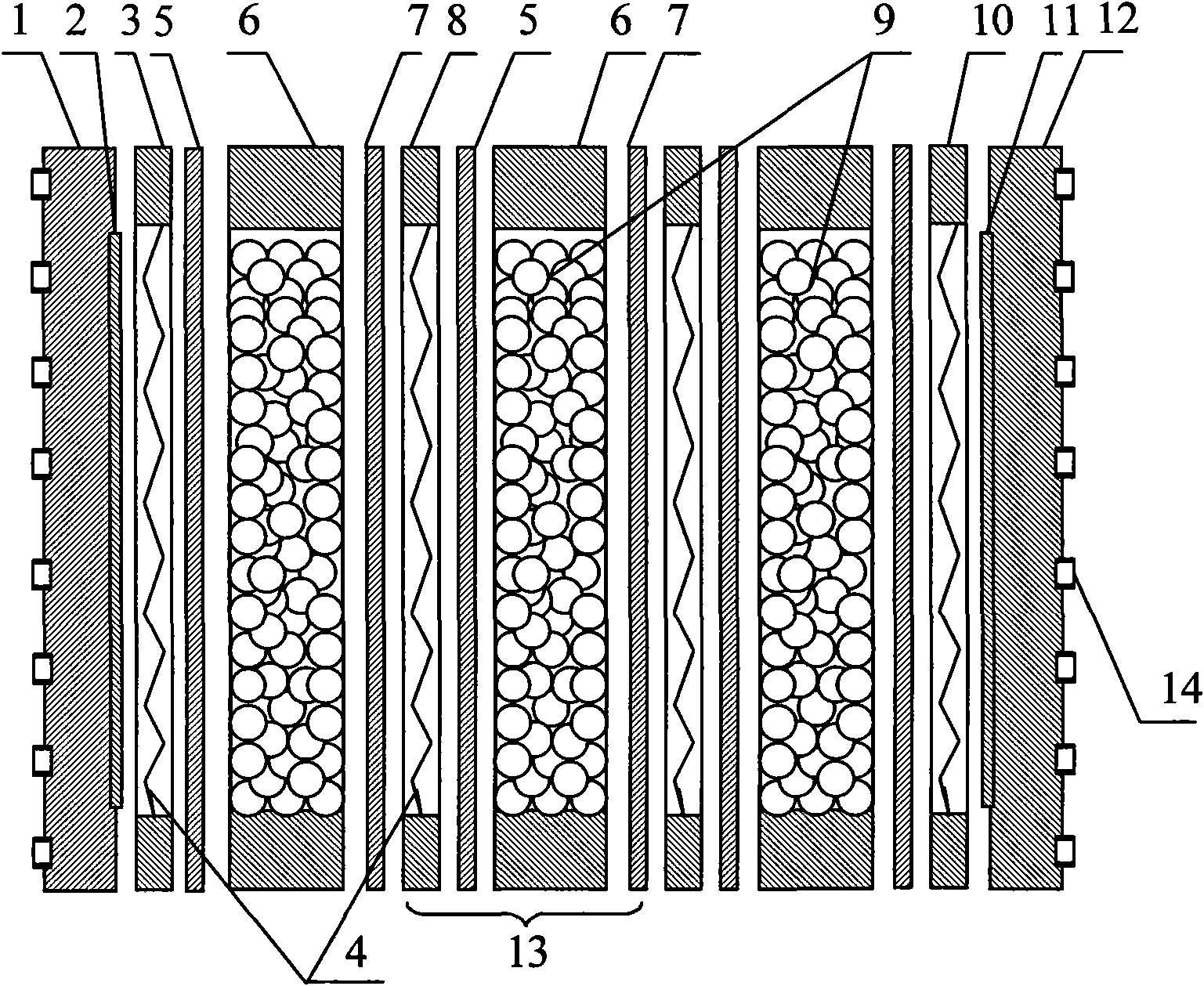

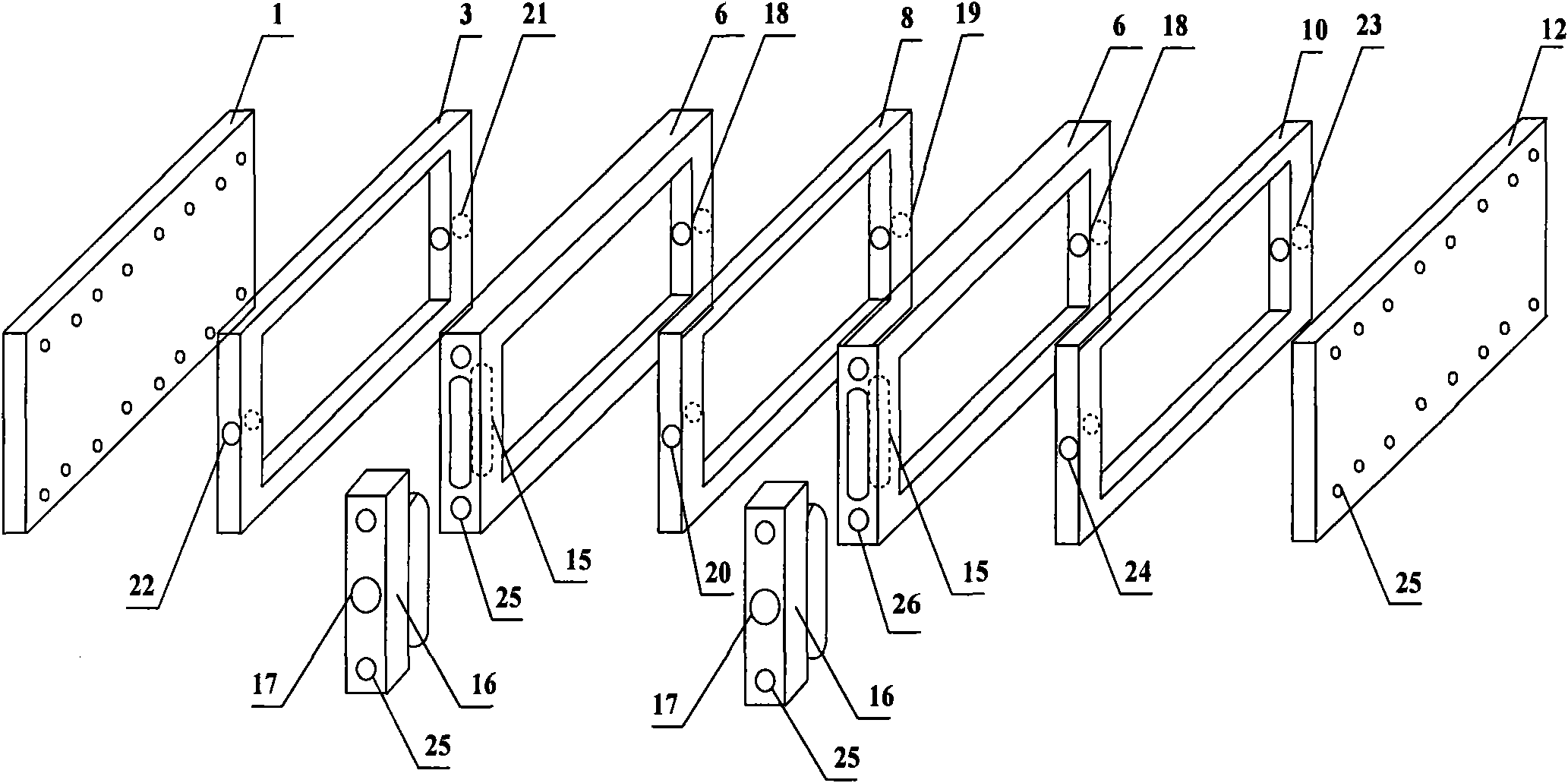

[0038] Such as figure 2 , image 3 As shown, a countercurrent operation ion exchange resin electrical regeneration device mainly includes a membrane stack, an electrode device and a clamping device.

[0039]The membrane stack is composed of several sets of membrane pairs 13, and each set of membrane pairs 13 includes the following components arranged in sequence: concentrated water chamber separator 8, anion exchange membrane 5, resin regeneration chamber separator 6 and cation exchange membrane 7, concentrated water chamber The partition 8 is a plate-and-frame structure, and its internal space forms a concentrated water chamber with the anion exchange membrane 5 and cation exchange membrane 7 on both sides, and the concentrated water chamber is filled with plastic diversion nets; the resin regeneration chamber partition 6 is also a plate-and-frame t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com