Remote automatic weighing system

An automatic weighing and metering system technology, which is applied in weighing, measuring devices, instruments, etc., can solve the problem of uneven load at vehicle inspection and weighing points, and achieve the effects of easy promotion, improved working environment, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

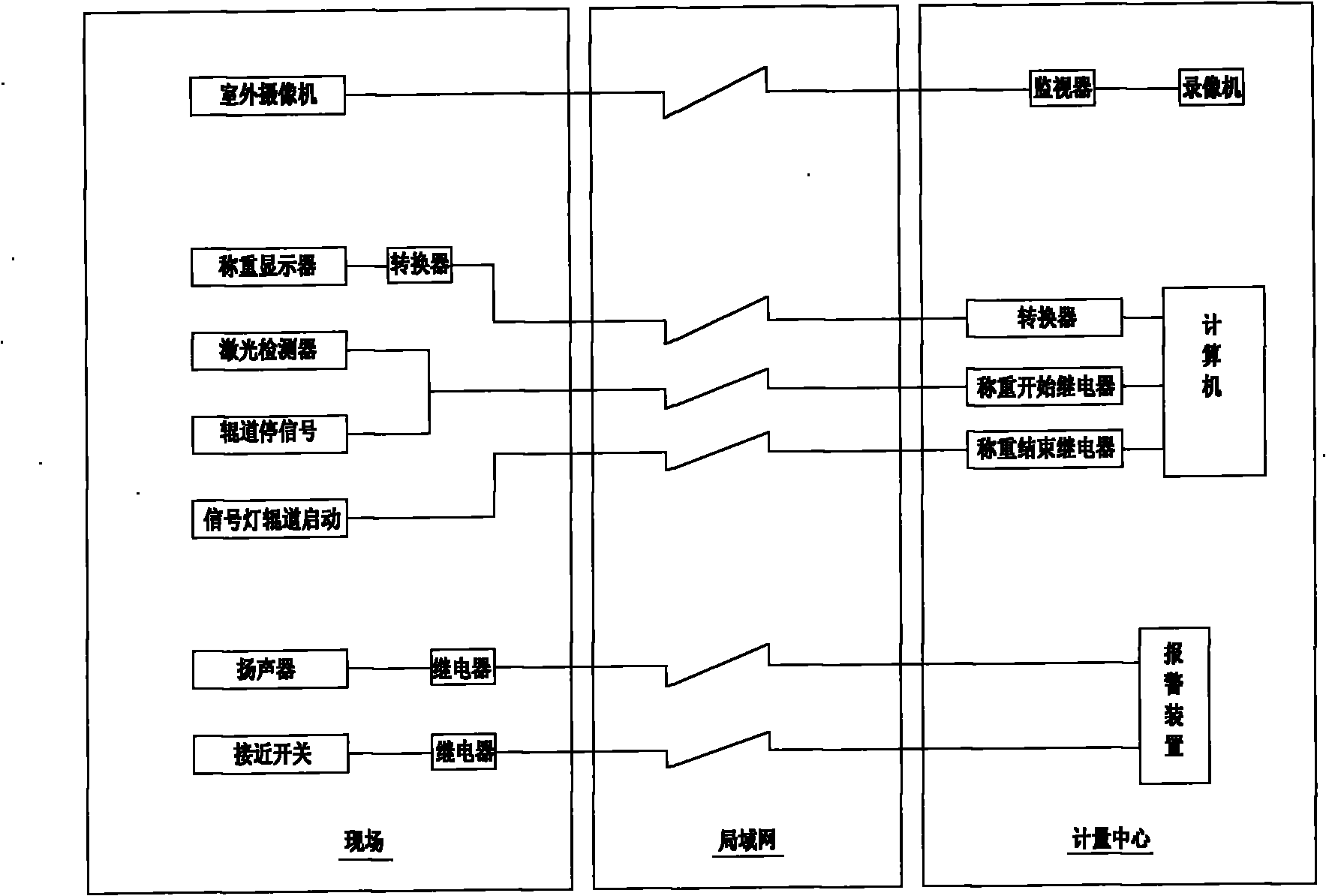

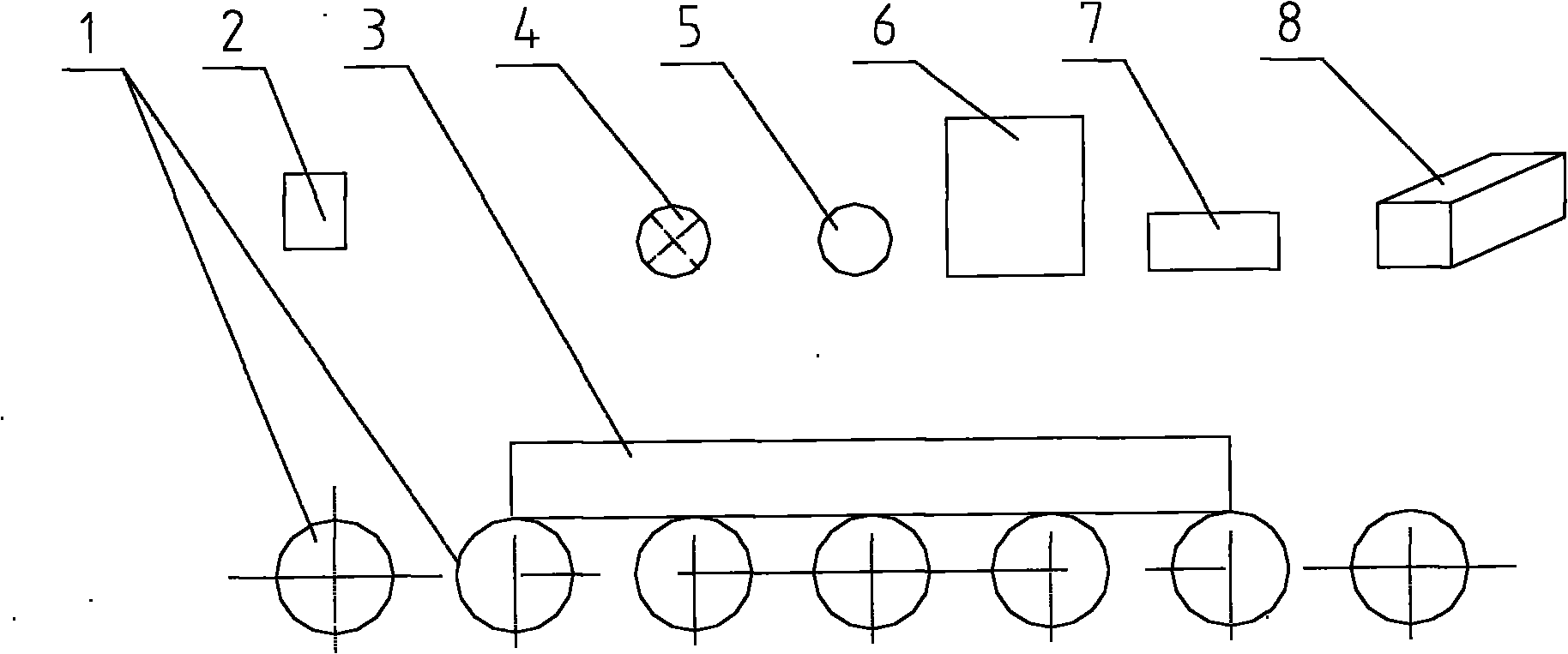

[0026] Example 1 as figure 1 , 2 Shown: a billet static roller scale of a remote automatic weighing and measuring system. After the laser detector 2 installed on the billet static roller scale collects the signal that the billet 3 enters the metering roller table 1, the electronic control system controls the metering roller Road 1 automatically decelerates and stops. The signal that the steel billet 3 enters the measuring roller table 1 is transmitted to the central computer through the 24V relay of the measuring center through the local area network at the same time, and the switching value board installed in the central computer is closed, and the central computer can continuously measure the weighing instrument 7 through the passive converter and the local area network. The sent data is collected; after the central computer collects the data, the weighing end signal is given by the switch board and the 24V relay, which is sent back to the on-site computer of the steel bill...

Embodiment 2

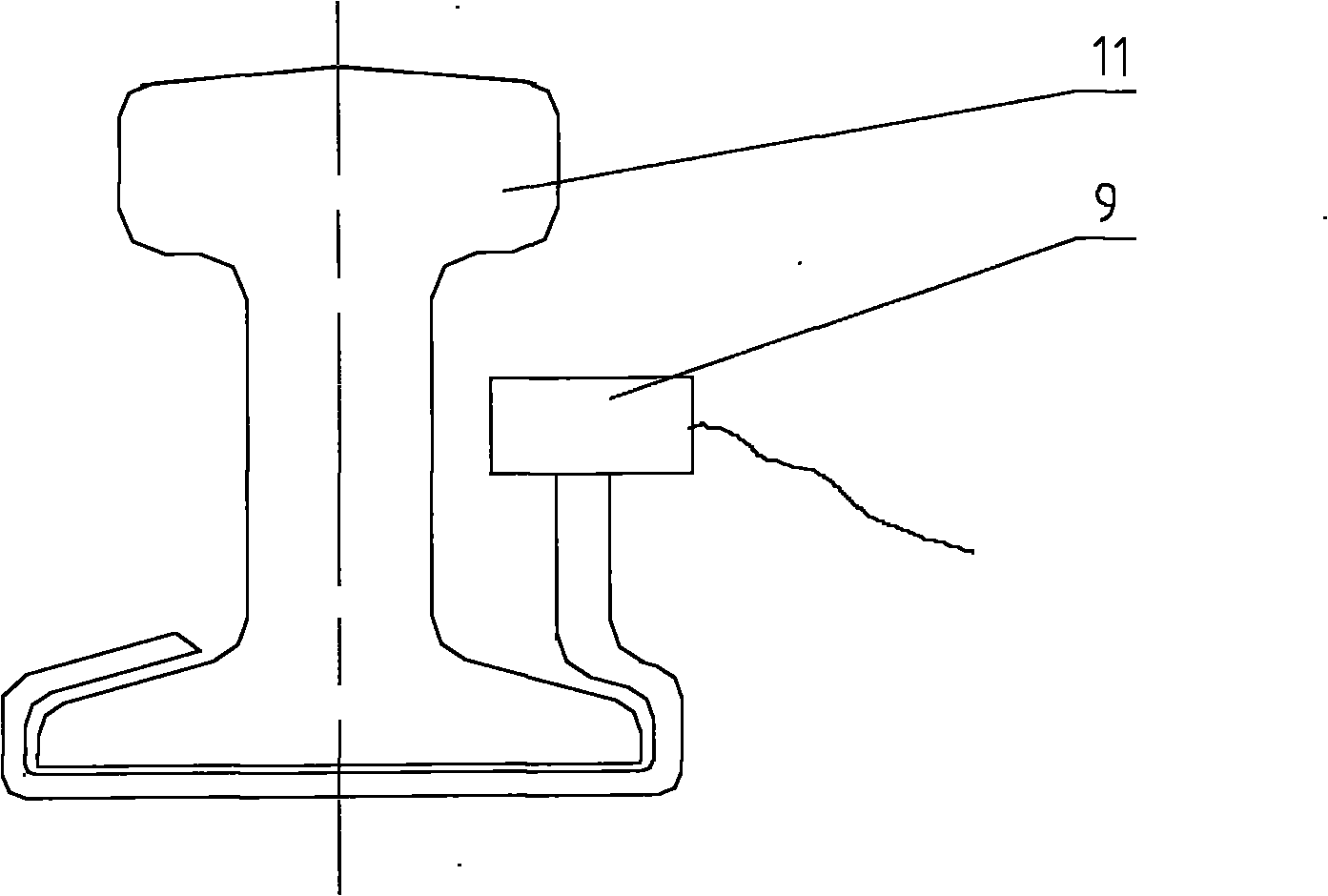

[0029] Example 2 as figure 1 , 3 , shown in 4: a kind of dynamic and static track scale of long-distance automatic weighing measurement system, after the magnetoelectric sensor 9 or proximity switch 10 that is installed on the rail 11 of track scale collects the signal that gross weight or tare compartment enters static track scale, The weighing instruments of the dynamic and static rail scales continuously send the marshalling information including the car number, product name, source, destination, and gross weight or tare data to the central computer of the metering center through the local area network, and enter the data into the central computer; the central computer will correspond to the vehicle number The gross weight and tare weight can automatically calculate the net weight and print the grouping information and measurement certificate. When the network is interrupted due to a fault, the marshalling information and gross weight or tare data are stored in the on-site...

Embodiment 3

[0030]Embodiment 3: A static truck scale for remote automatic weighing and measurement. After the magnetic sensor 9 or proximity switch 10 installed on the static truck scale collects the signal that the gross weight or tare weight of the car enters the truck scale, the static truck scale The weighing instrument continuously sends the data including vehicle number, product name, source, destination, gross weight or tare weight to the central computer of the measurement center through the local area network, and enters the data into the computer; the central computer records the corresponding gross weight and tare according to the vehicle number. The weight automatically calculates the net weight and prints a complete bill including shipping information and measurements. When the network is interrupted due to a failure, the transportation information and gross weight or tare data are stored in the on-site computer to ensure the normal operation of the measurement. After the netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com