Preparation method of trenches of polyimide-embedded syconoid ridge type devices

A technology of polyimide and its production method, which is applied in the field of lithography process for manufacturing semiconductor devices, and can solve problems such as difficult lithography process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0027] Taking a double-groove ridge laser with a wavelength of 1.5um as an example, after implementing the manufacturing method of the polyimide-filled double-groove ridge device channel of the present invention, the operation is as follows:

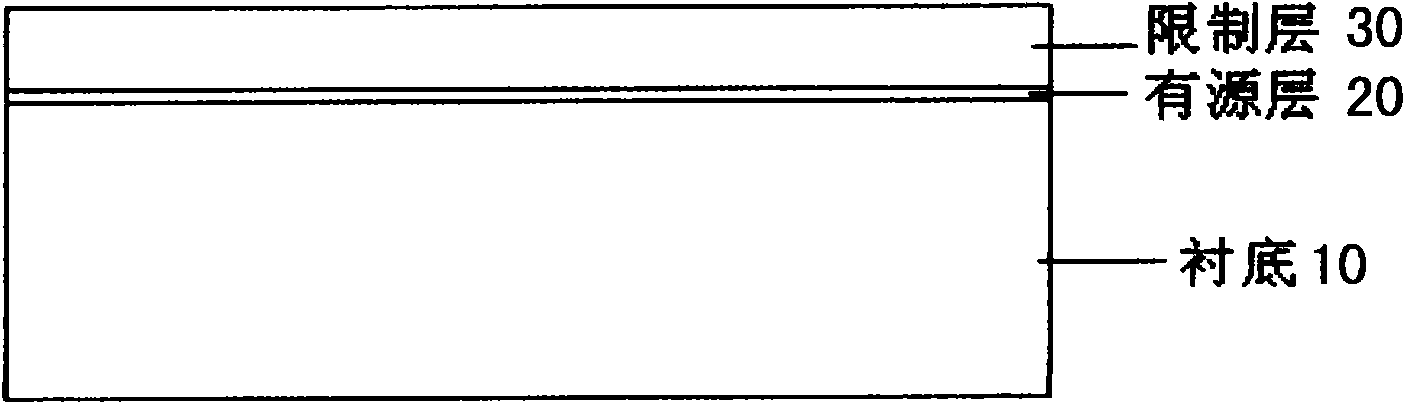

[0028] Step 1: growing an active layer 20 and a confinement layer 30 on the surface of the substrate 10;

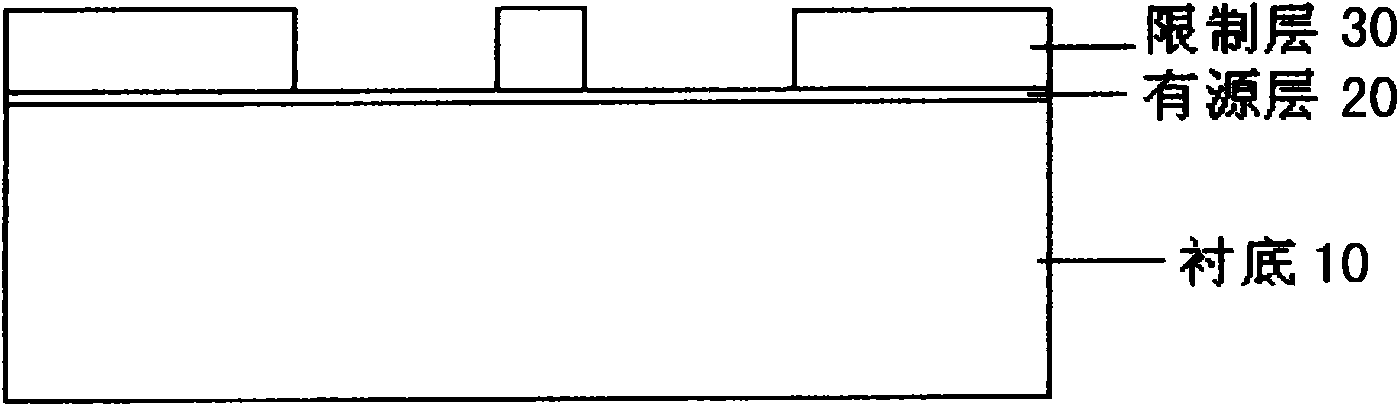

[0029] Step 2: making a photolithography pattern on the surface of the confinement layer 30;

[0030] Step 3: photolithography, etching a double-groove-ridge structure on the surface of the confinement layer 30, and the etching depth reaches the surface of the active layer 20;

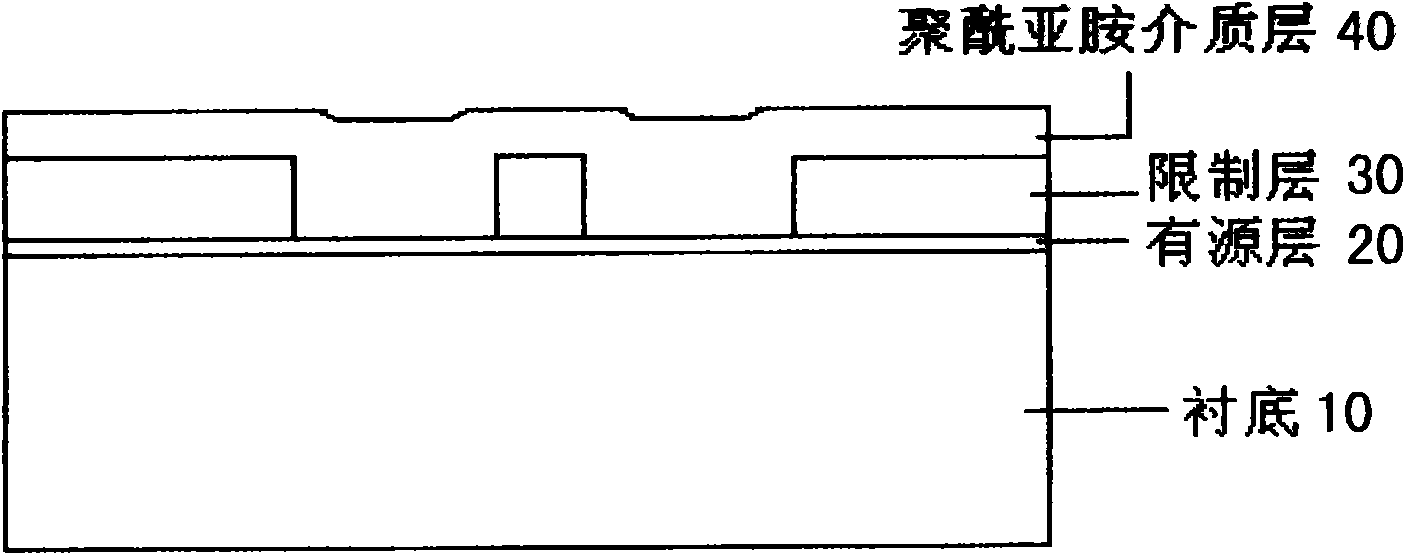

[0031] Step 4: Coat the polyimide dielectric layer 40 in the double-groove ridge structure and the surface of the limiting layer 30 for pre-curing; the pre-curing time is 20-40 minutes, using a desktop electric drying oven, and the curing temperature is 110- 120°C;

[0032] Step 5: Apply photoresist 50 on the surface of polyimide dielectric layer 40, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com