Constant current control method and circuit of multipath paralleled LED power supply

A technology of LED power supply and constant current control, which is applied in the direction of electric lamp circuit layout, electric light source, light source, etc., to achieve the effect of solving light difference and light decay and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

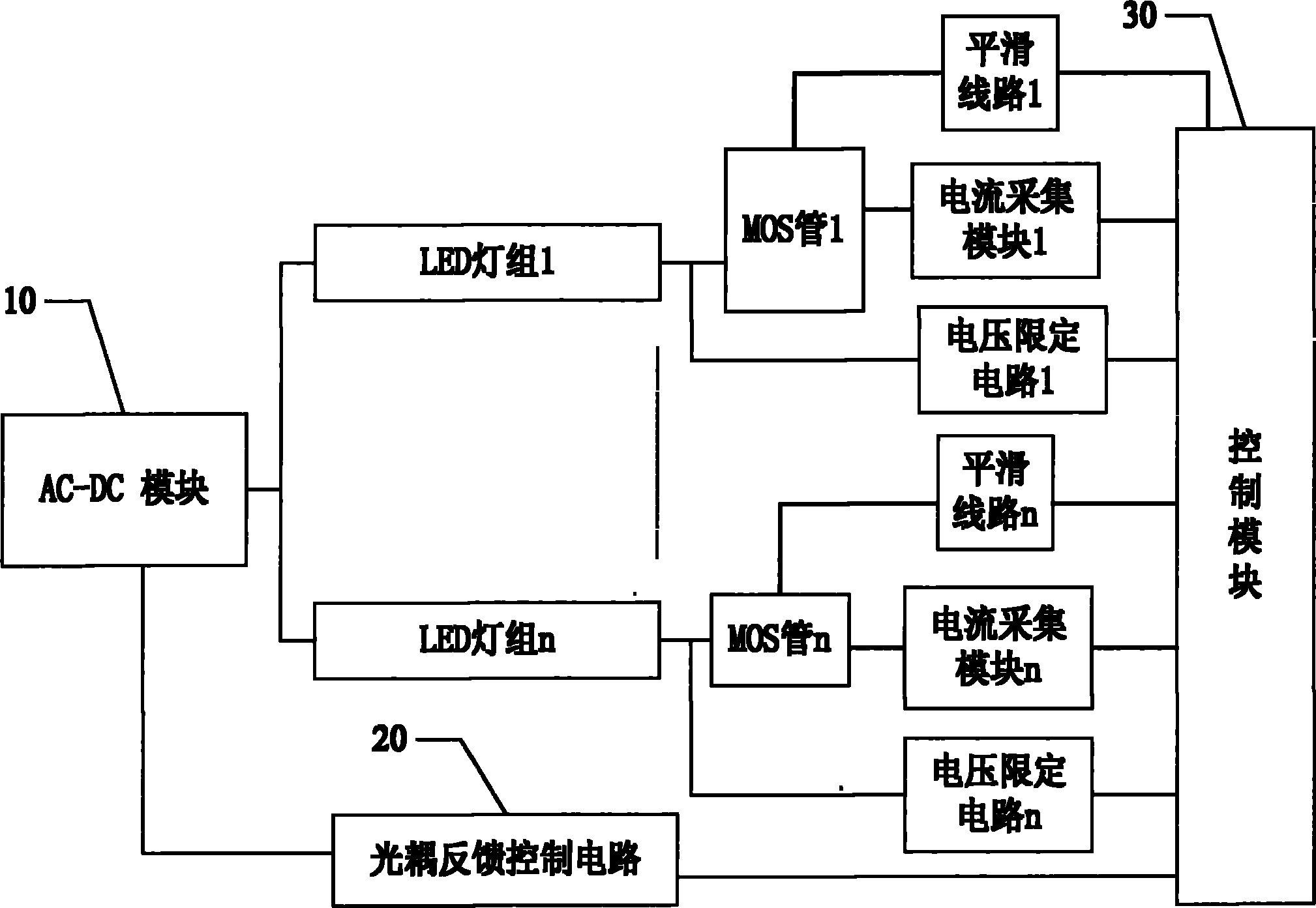

[0034] see image 3 , is a functional block diagram of the multi-channel parallel constant current control circuit of the LED power supply of the present invention, which includes an AC-DC module 10, a control module 30, and an optocoupler feedback control circuit 20 connected between the AC-DC module 10 and the control module 30 , and LED lights. There are at least one set of LED lamp groups, namely LED lamp group 1 to LED lamp group n. Each LED lamp group is equipped with a MOS tube, a current acquisition module, a smoothing line and a voltage limiting circuit, for example: one end of the LED lamp group 1 is connected to the AC-DC module 10, and the other end is connected to the MOS tube 1; One end of the current acquisition module 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com