Variable frequency hydraulic control system of fuel dispenser and quantitative refueling control method thereof

A technology of hydraulic control system and control method, applied in the direction of liquid distribution, conveying or transfer device, special distribution device, packaging, etc., can solve the problem of reducing motor and pump efficiency, vibration and noise connecting parts, hydraulic components and measuring instruments damage, etc. problems, to achieve the effect of improving the water hammer effect, simplifying the internal structure, and controlling the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

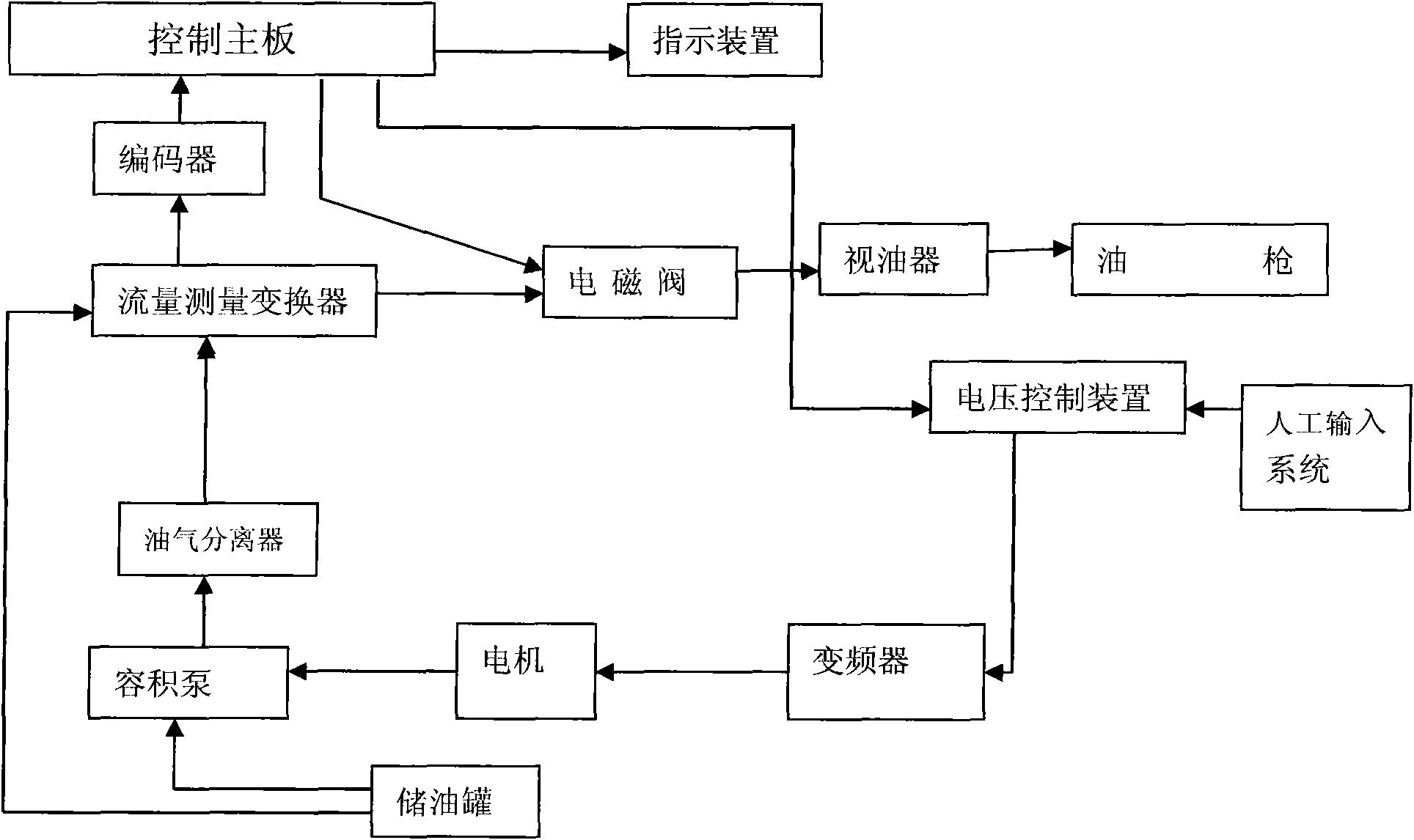

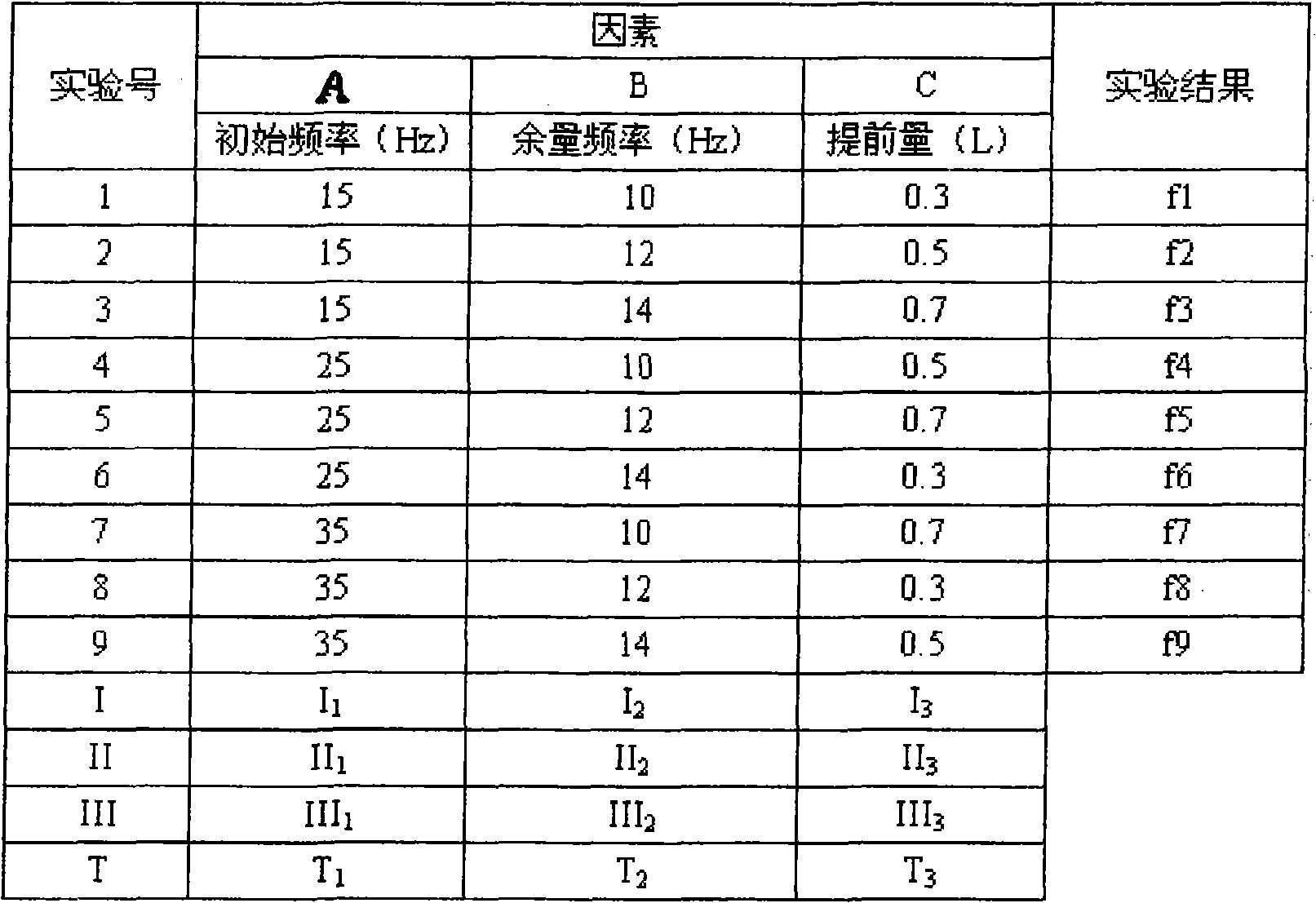

[0024] The structural block diagram of the frequency conversion hydraulic control system of the fuel tanker with a single-valve structure solenoid valve is as follows: figure 1As shown, including interconnected motor, frequency converter, positive displacement pump, oil and gas separator, flow measurement transducer, encoder, control board with counter, indicating device, solenoid valve, oil sight, oil gun, manual input device and The voltage control device, wherein the solenoid valve is a solenoid valve with a single valve structure. The controllable factors affecting the refueling accuracy of the frequency conversion hydraulic control system of the fuel tanker are analyzed by orthogonal test method:

[0025] Refueling accuracy, that is, the relative error of the refueling amount, that is, the relative error between the actual refueling amount and the nominal refueling amount. During the test, the method of quantitative refueling is adopted for the fuel dispenser, such as qu...

Embodiment 2

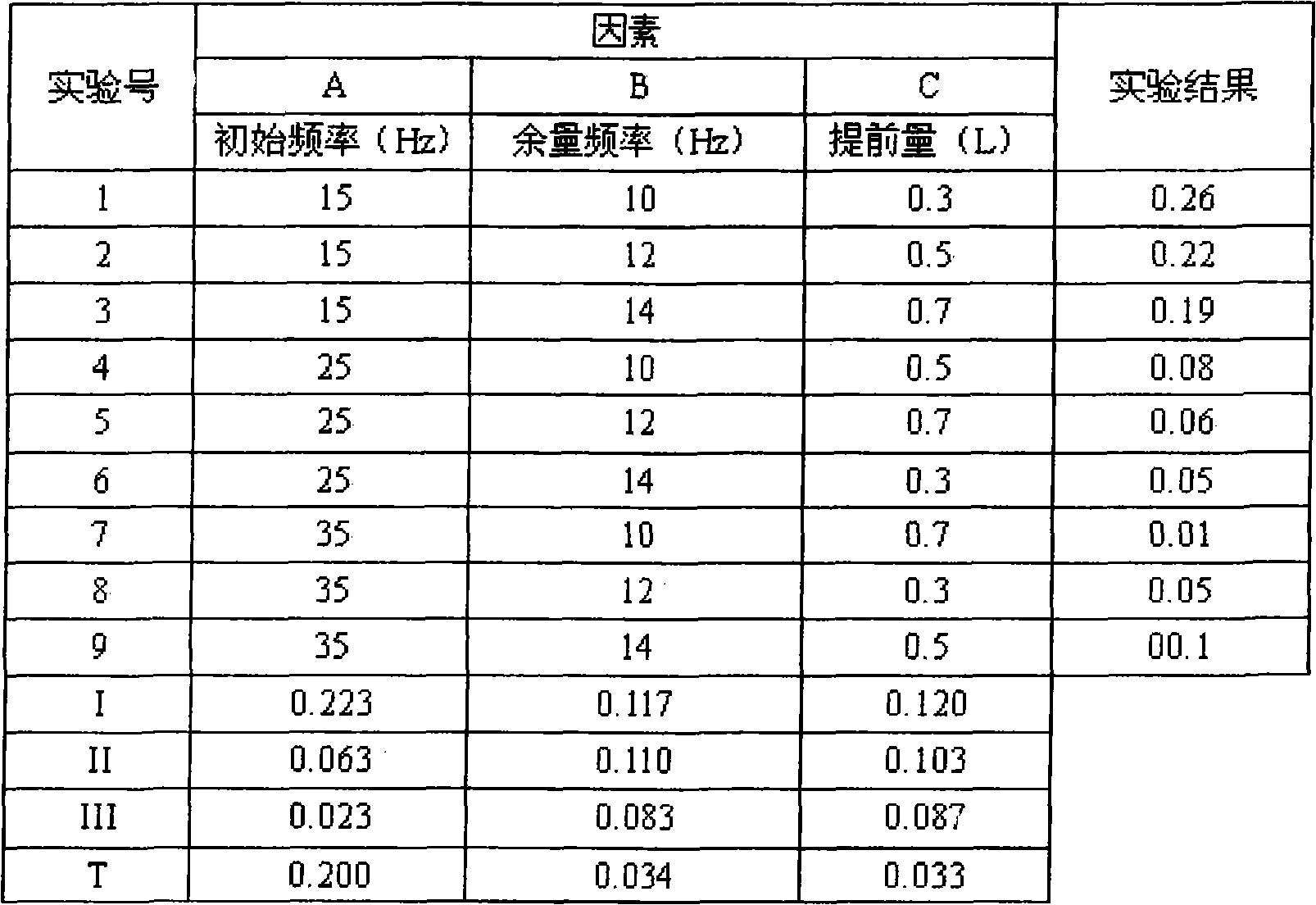

[0049] For example figure 1 The frequency conversion hydraulic control system of the fuel tanker shown is tested for fueling accuracy at different initial frequencies and different margin frequencies to verify the fueling accuracy of the fuel tanker after changing the solenoid valve with a double-valve structure to a solenoid valve with a single-valve structure Can it be kept within the range required by the state (that is, the fueling accuracy is between ±0.3%) and achieve better results. Among them, the initial frequency is the frequency of the motor at the beginning of refueling, and the remaining frequency is the frequency of the motor when the last 0.3L of oil is added.

[0050] After experimental testing, the following results are obtained, as shown in Tables 3, 4, and 5, which are the relative error of refueling (that is, refueling accuracy) of the variable frequency refueling machine at different initial frequencies and different margin frequencies. Among them, Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com