Telescopic supporting leg and application thereof

A technology of telescopic outriggers and outrigger boxes, which is used in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc. problems, to achieve the effect of easy to ensure machining accuracy, reduce wear, and the failure of telescopic outriggers, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

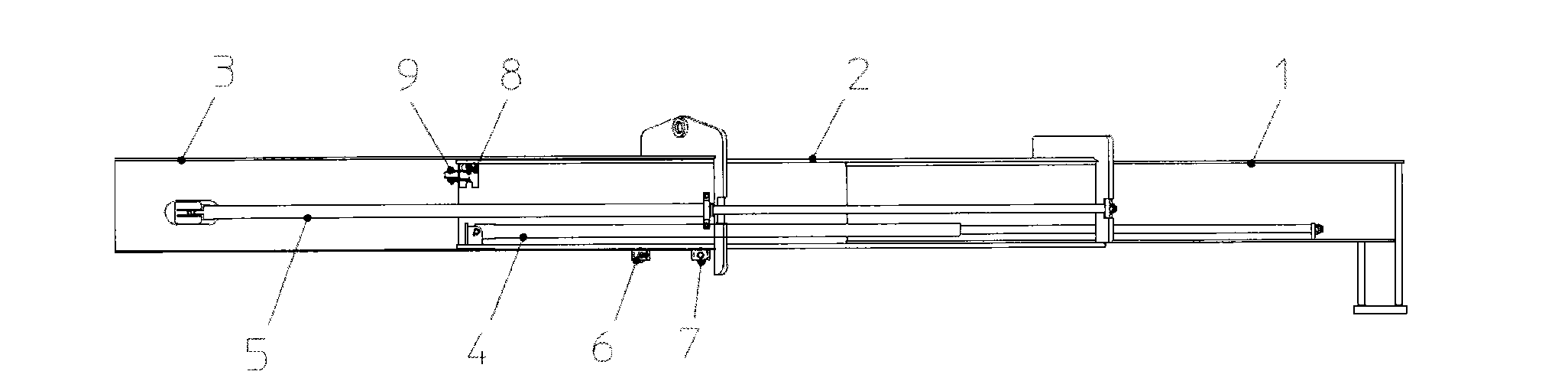

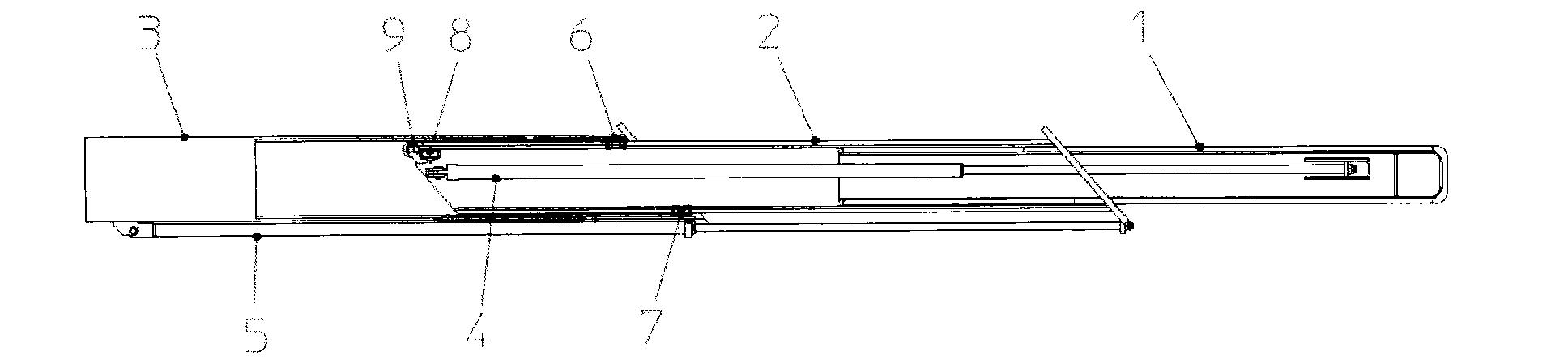

[0014] Such as figure 1 and figure 2 As shown, the telescopic outrigger structure provided in this implementation is mainly composed of the following parts: supporting leg 1, outrigger box 2, supporting outrigger telescopic oil cylinder 4, outrigger box telescopic oil cylinder 5, outrigger box lower roller structure-6 , Outrigger box lower roller structure two 7, outrigger box upper roller structure 8, outrigger box side roller structure 9. Wherein, in order to better explain the problem, the fuel tank case structure 3 is shown in the figure as a reference structure.

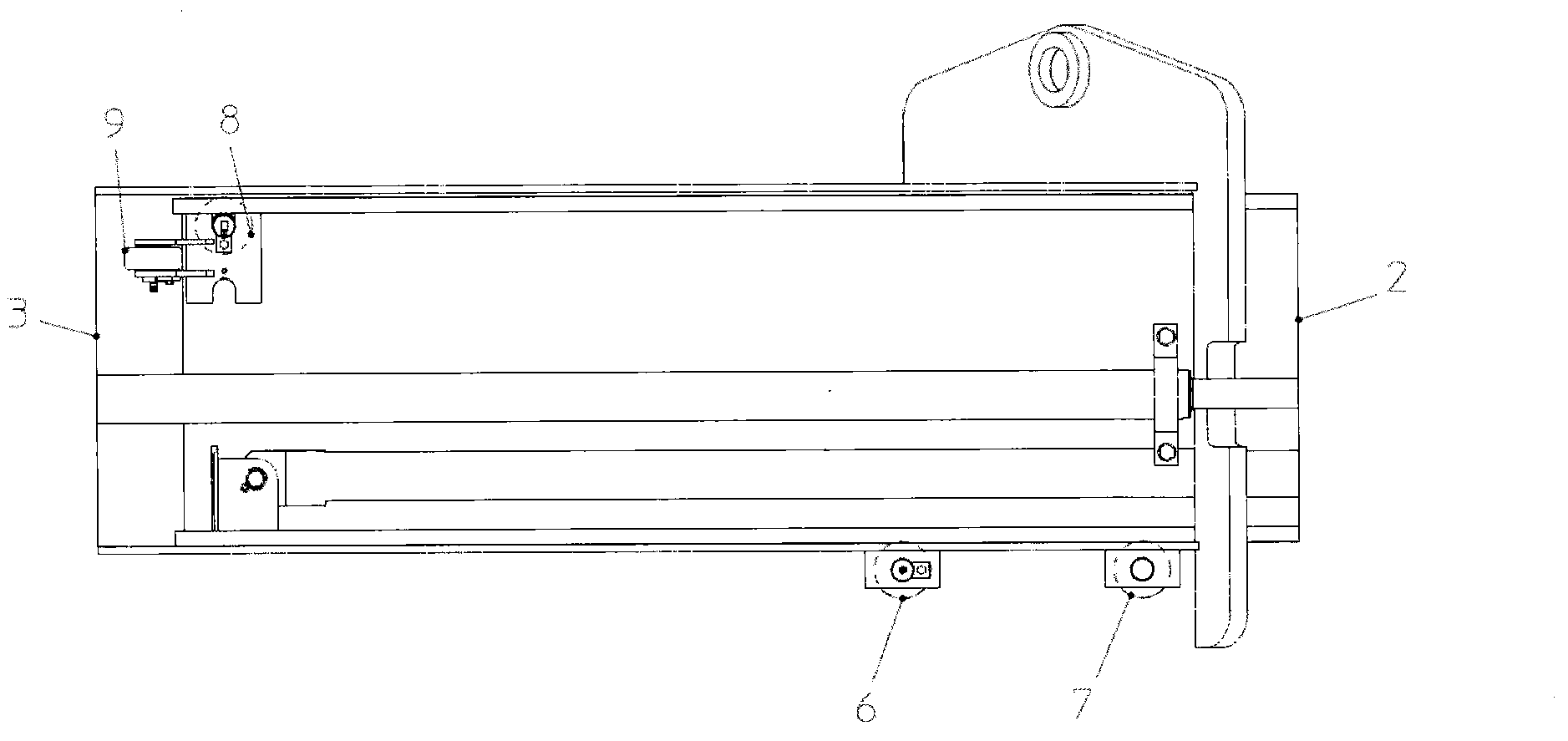

[0015] The partially enlarged schematic diagram of the telescopic outrigger is shown in image 3 .

[0016] The supporting leg 1, the outrigger box 2 and the fuel tank box structure 3 are nested inside and outside, wherein the supporting leg 1 is placed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com