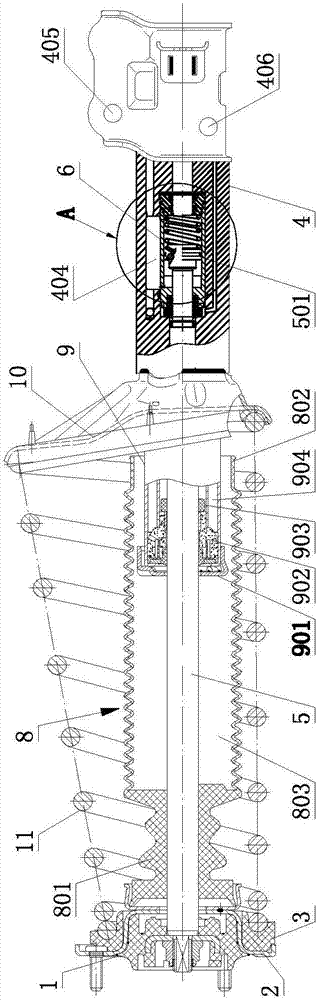

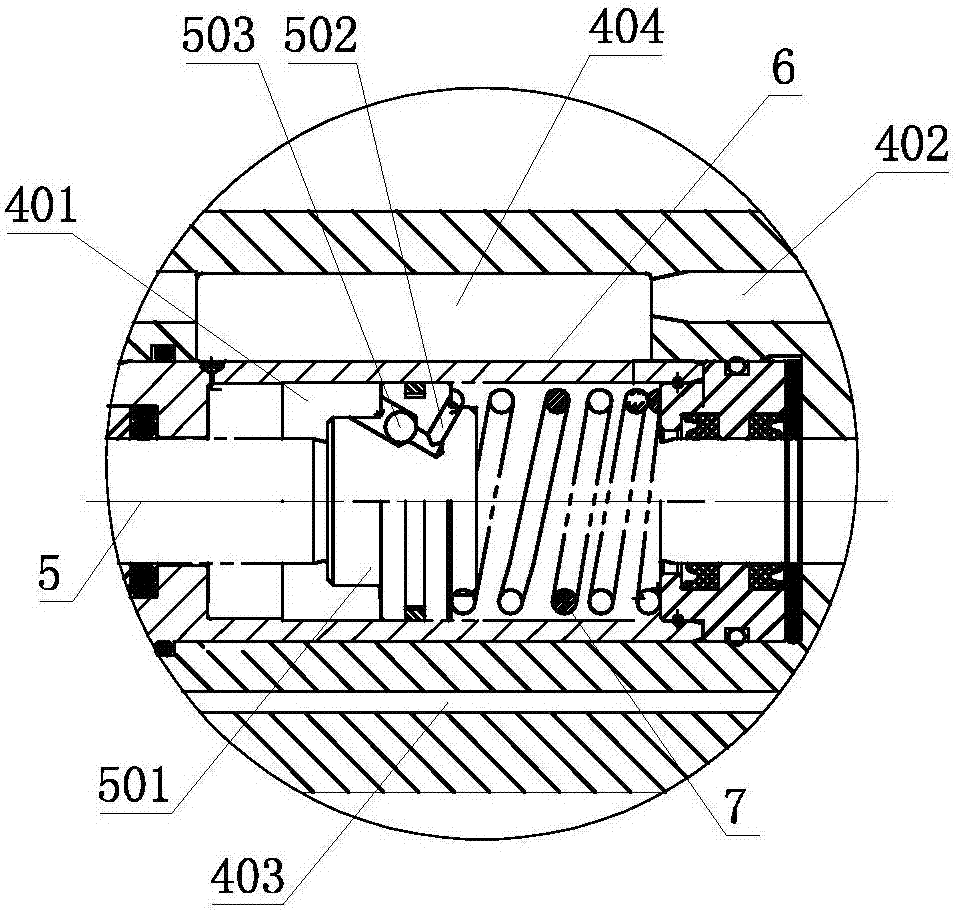

Novel car shock absorber assembly

An automobile shock absorber and assembly technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of short service life, easy failure of shock absorber rebound ability, and poor shock absorption effect And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

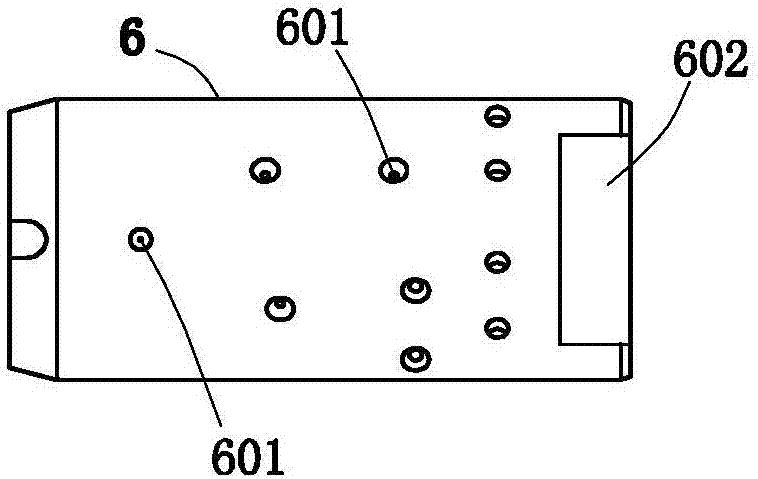

Method used

Image

Examples

preparation example 1

[0063] S1: Weigh 108 parts by mass of a three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 5 parts by mass of styrene-based thermoplastic elastomer (TPES) and 3 parts by mass of polyamide-based thermoplastic elastomer (TPAE) ), 1 part by mass of SiC whisker with a length of 0.1-0.2mm, 2 parts by mass of thiodipropionate dilaurate, 0.1 part by mass of di-n-butyltin dilaurate, 0.3 part by mass of ethylene-vinyl acetate copolymer ( EVA), 0.6 parts by mass of methacryloxypropyltrimethoxysilane, 1.2 parts by mass of 4,4'-diaminobiscyclohexylmethane, and 2 parts by mass of silica powder with a particle size of 50-100 nm;

[0064] S2: Add SiC whiskers, thiodipropionate dilaurate, ethylene-vinyl acetate copolymer (EVA), and methacryloyloxy propylene to the three-component composite elastic base material. Trimethoxysilane (ie 0.12 parts by mass) and 80% of the total amount of 4,4'-diaminobiscyclohexylmethane (ie 0.96 parts by mass), the resul...

preparation example 2

[0067] S1: Weigh 112 parts by mass of a three-component composite elastic base material (consisting of 100 parts by mass of nitrile rubber, 10 parts by mass of styrene-based thermoplastic elastomer (TPES) and 2 parts by mass of polyamide-based thermoplastic elastomer (TPAE) ), 2 parts by mass of SiC whiskers with a length of 0.1-0.2mm, 1 part by mass of thiodipropionate dilaurate, 0.3 parts by mass of di-n-butyltin dilaurate, 0.2 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.9 parts by mass of methacryloxypropyltrimethoxysilane, 1 part by mass of 4,4'-diaminobiscyclohexylmethane and 3 parts by mass of silica powder with a particle size of 50-100 nm;

[0068] S2: Add SiC whiskers, thiodipropionate dilaurate, ethylene-vinyl acetate copolymer (EVA), and 30% methacryloxy propylene to the three-component composite elastic base material Trimethoxysilane (ie 0.27 parts by mass) and 70% of the total amount of 4,4'-diaminobiscyclohexylmethane (ie 0.7 parts by mass), the resu...

preparation example 3

[0071] S1: Weigh 110 parts by mass of a three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 7.5 parts by mass of styrene-based thermoplastic elastomer (TPES) and 2.5 parts by mass of polyamide-based thermoplastic elastomer (TPAE) ), 1.5 parts by mass of SiC whiskers with a length of 0.1-0.2 mm, 1.5 parts by mass of thiodipropionate dilaurate, 0.2 parts by mass of di-n-butyl tin dilaurate, 0.25 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.8 parts by mass of methacryloxypropyltrimethoxysilane, 1.1 parts by mass of 4,4'-diaminobiscyclohexylmethane, and 2.5 parts by mass of silica powder with a particle size of 50-100 nm;

[0072] S2: Add SiC whiskers, thiodipropionic acid dilaurate, ethylene-vinyl acetate copolymer (EVA), and 25% of the total amount of methacryloxy propylene to the three-component composite elastic base material Trimethoxysilane (ie 0.2 parts by mass) and 75% of the total amount of 4,4'-diaminobiscyclohexy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com