Carbonation wooden wall and construction method thereof

A technology of carbonized wood walls and carbonized wood, which is applied in the field of architectural decoration walls, can solve the problems of no environmental protection function, poor wall decoration effect, low construction efficiency, etc., achieve rich and colorful visual impact, and avoid artificial manufacturing trace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

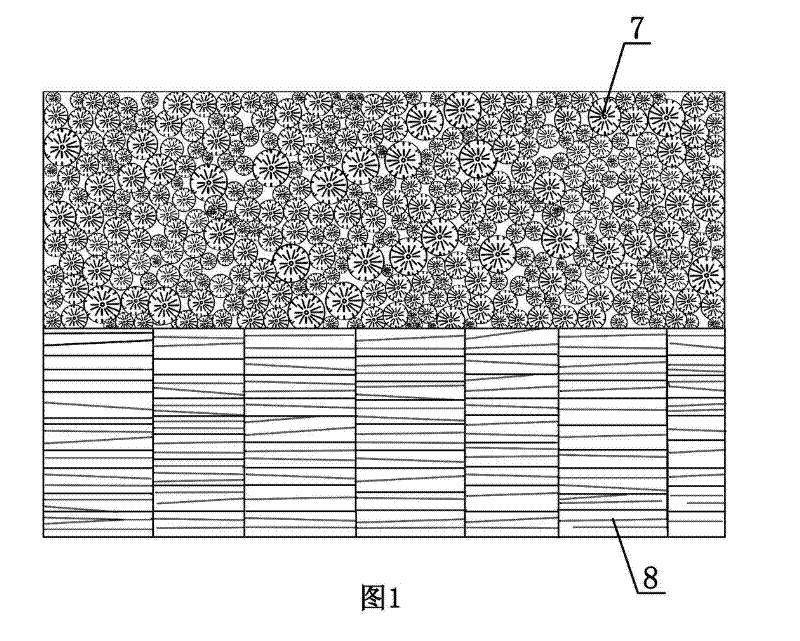

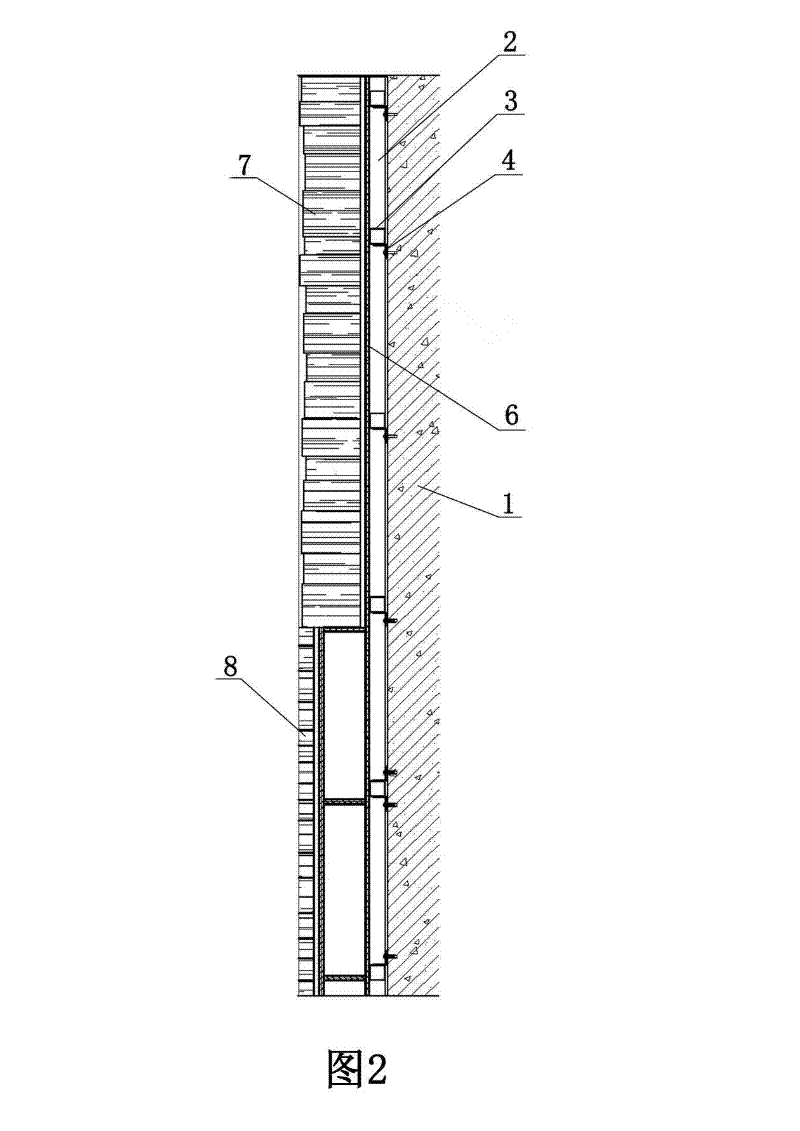

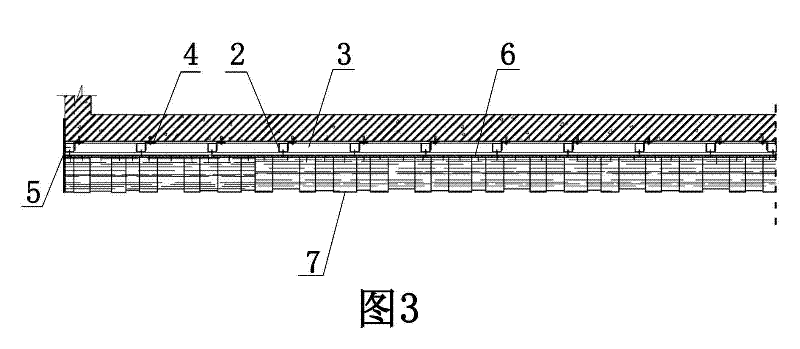

[0041] Examples see Figure 1-4 As shown, this carbonized wood wall includes a wall base 1, on which a dragon skeleton, a wooden plywood base 6 and a carbonized wood surface layer are sequentially connected, and the side of the carbonized wood wall is connected with an edge-sealing steel plate 5 ;

[0042] The keel frame is a grid structure formed by connecting the horizontal keel 3 and the vertical keel 2, the vertical keel 2 is fixed with the wall base 1 by the angle steel connector 4, the horizontal keel 3 is connected between the vertical keels 2, the vertical keel 2 and the wall base 1 are fixed. The transverse keels 3 are all square steel keels;

[0043] The edge-sealing steel plate 5 is connected with the vertical keel 2 at the side of the carbonized wood wall by bolts;

[0044] The wooden splint base layer 6 is assembled by wooden splint unit blocks, the back of the wooden splint unit block is fixed on the vertical keel 2 by screws, and the front of the wooden splint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com