Crank of pumping unit

An oil pumping unit and crank technology is applied in the field of improving the crank structure of the oil pumping unit, which can solve the problems of heavy design, and achieve the effects of reducing the overall weight, improving the manufacturability, and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

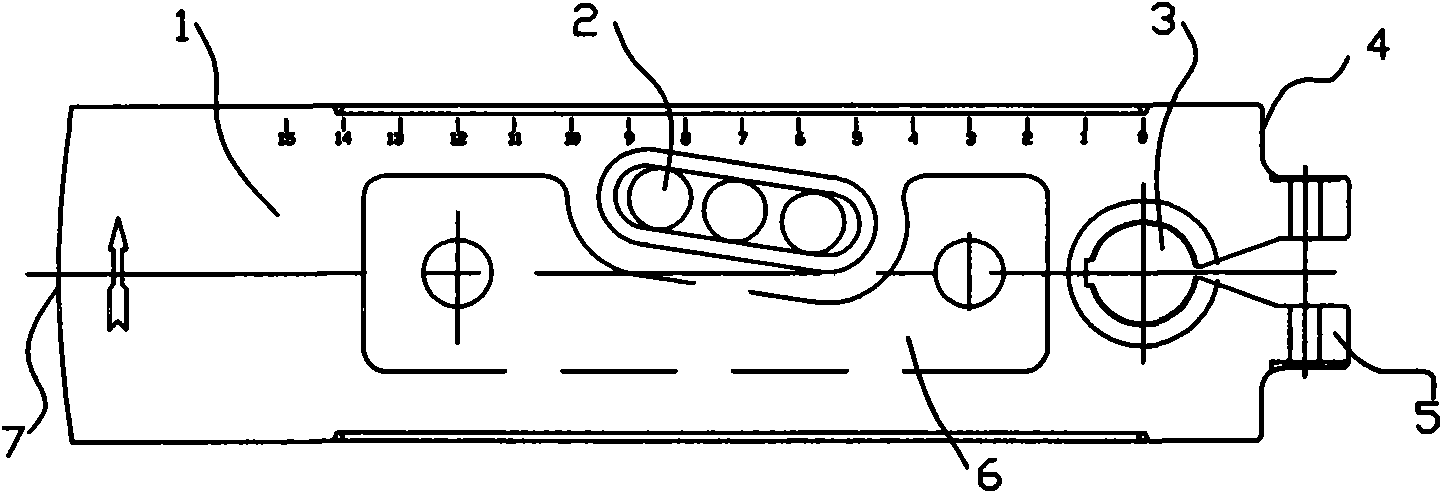

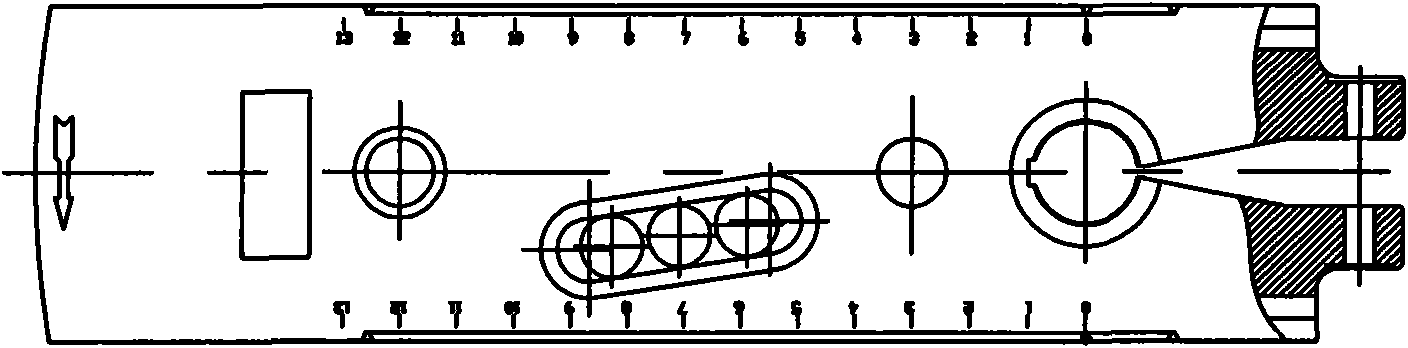

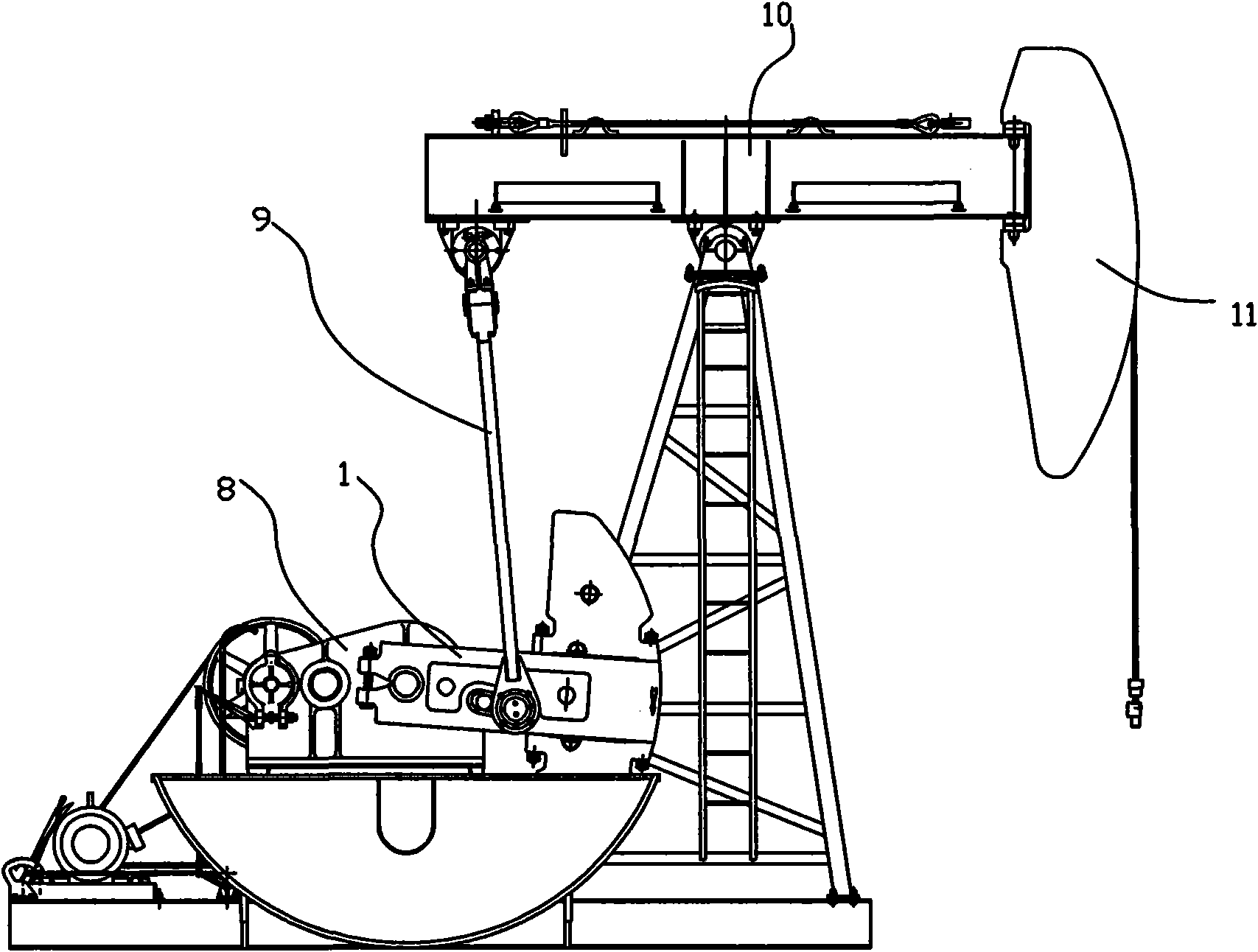

[0011] The invention as figure 1 As shown, the top end of the crank body 1 is provided with a shaft hole 3 for connecting the drive shaft, the middle part of the crank body 1 is provided with a connecting hole 2 for connecting the living hinge to the connecting rod of the pumping unit, and the middle part of the crank body 1 is provided with a groove 6, so that The thickness is reduced and the weight is reduced. The distance between the tail end 7 of the crank body 1 and the shaft hole 3 is lengthened, and the thickness of the tail end 7 is thickened, and the distance between the top edge 4 of the crank body 1 and the shaft hole 3 is shortened. The volume formed by lengthening and thickening is smaller than the volume formed by thinning and shortening.

[0012] When applying the present invention, the lengthening of the tail end 7 will adapt to the profile of the pumping unit shield, and it can be lengthened as much as possible when space permits. When the amount of lengthen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com