Slope rill erosion measurer

A technology for measuring instruments and slopes, applied in measuring devices, measuring inclinations, mechanical measuring devices, etc., can solve the problems of expensive instruments, large amount of data acquisition, long measurement time, etc., and achieve improved measurement accuracy and simple data processing , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

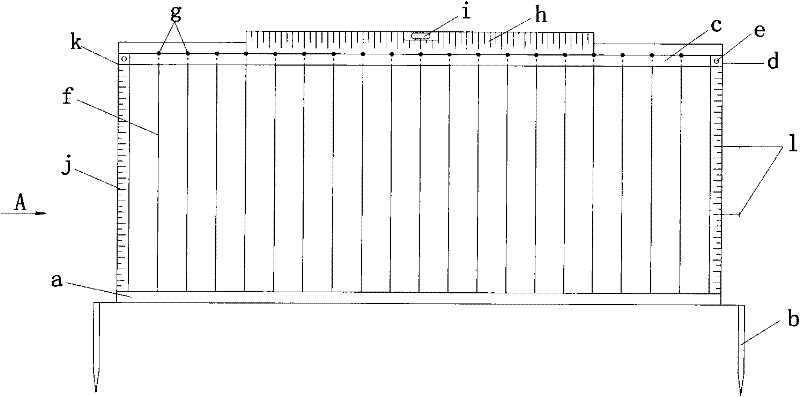

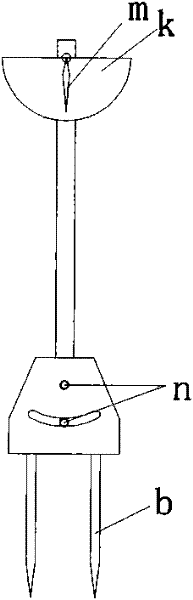

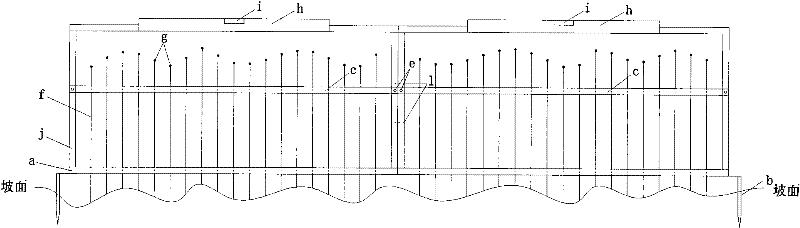

[0032] exist figure 1 and figure 2 Among them, the aluminum alloy frame (a) is the main body of the slope surface gully erosion measuring instrument, the fixing braze (b) is connected to its bottom through the fixing screw (n), inserted into the slope surface to fix the measuring instrument, and the two ends of the sliding beam (c) have The clamp (d) is set on the aluminum alloy frame (a) and can slide up and down. By adjusting the elastic screw (e) above, the sliding crossbeam can be fixed at any position on the frame. The upper end of the stylus (f) is connected with a nut (g), and the lower end passes through the sliding beam and is inserted into the frame. A horizontal scale (h) and a level (i) are connected to the upper end of the frame, a protractor (k) and a vertical scale (j) are connected to the left side, and there is a freely rotating pointer (m) at the center of the protractor. There are two set bolts (l) on the right side of the frame to which another gauge can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com