Helium mass spectrum leak detection fixture for tube plate welding seams of evaporator

A technology of evaporator tube sheet and helium mass spectrometry, which is applied in the field of mechanical devices, can solve the problems of low efficiency and high consumption of O-rings, etc., and achieve the effect of labor-saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

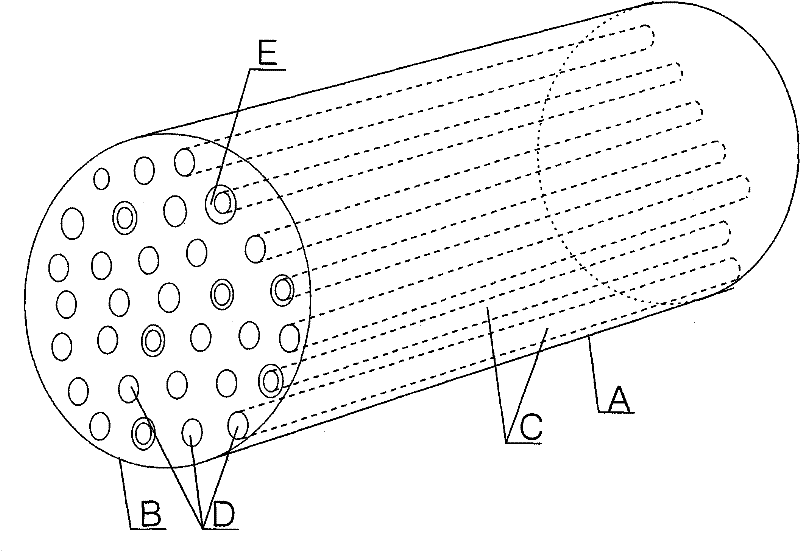

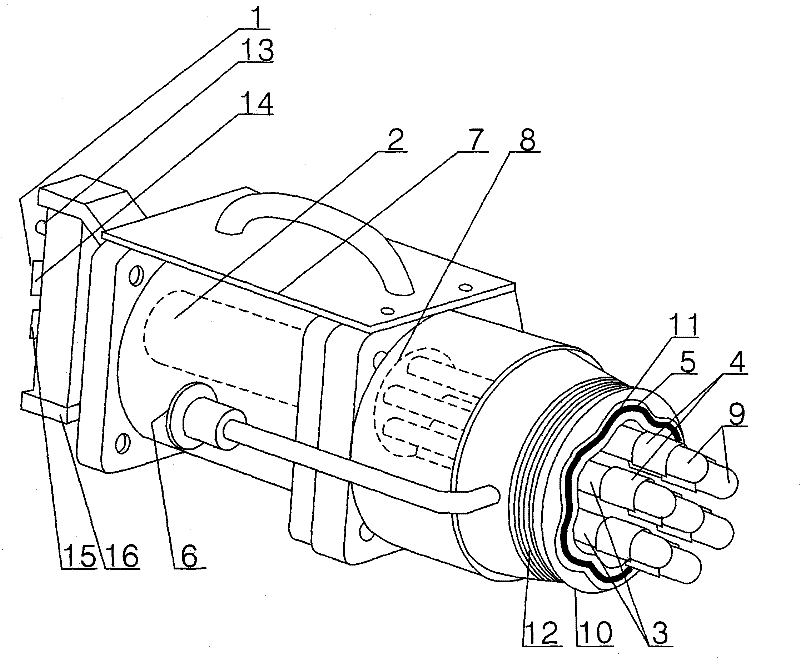

[0023] Such as Figure 2-Figure 5 As shown, the main body of the helium mass spectrometer leak detection fixture is composed of an electric control box 1, a cylinder 2, a set of movable cores 3, a static seal ring 5, a set of dynamic seal rings 4 set on a set of movable cores 3, and a detection port 6 Composition, the fixture main body 7 is connected with the leak detector, and there is a mechanical pump inside the leak detector. According to the hole spacing and layout of the weld seam on the surface of the evaporator tube plate, the group of movable cores 3 can be designed into four, five, six, seven, eight, nine and other arbitrary activities according to the number and layout of the tube bundle holes. The number of cores, the present embodiment takes seven cores as an example to form a group of movable cores 3, which are located inside the fixture body 7 and extend out of the side end surface of the fixture, and are connected with the cylinder 2 with a connecting plate 8, ...

Embodiment 2

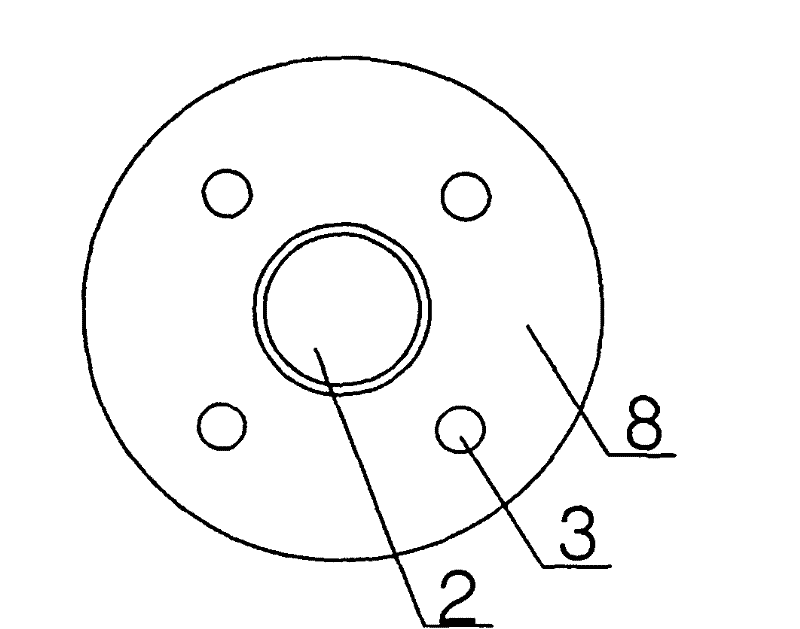

[0029] Such as Figure 6 As shown, in the case of keeping the above-mentioned main structure unchanged, the second embodiment takes four cores as an example to form a group of movable cores 3, which are arranged inside the fixture main body 7, and are connected with the cylinder 2 by a connecting plate 8, which can be used at the same time The shaft synchronously moves telescopically with the cylinder 2, and each movable core 3 is respectively covered with a dynamic sealing ring 4. An end face flange 10 is provided at the front end of the fixture main body 7 , and a seal groove 11 is opened on the end face of the end face flange 10 , and a static sealing ring 5 is installed in the seal groove 11 . The sealing groove 11 where the static sealing ring 5 is placed and the static sealing ring 5 adopt a curved shape according to the layout of the inspected seal welding seam on the surface of the tube sheet and the weld scars on the surface of the tube sheet, and the specific design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com