An engine ignition switch and its automatic manufacturing system

An automatic manufacturing system, ignition switch technology, applied in the direction of electrical switches, contact electrical connections, electrical components, etc., can solve the problems of low production efficiency, prone to waste products, etc., to reduce labor costs, avoid leakage, and simplify complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

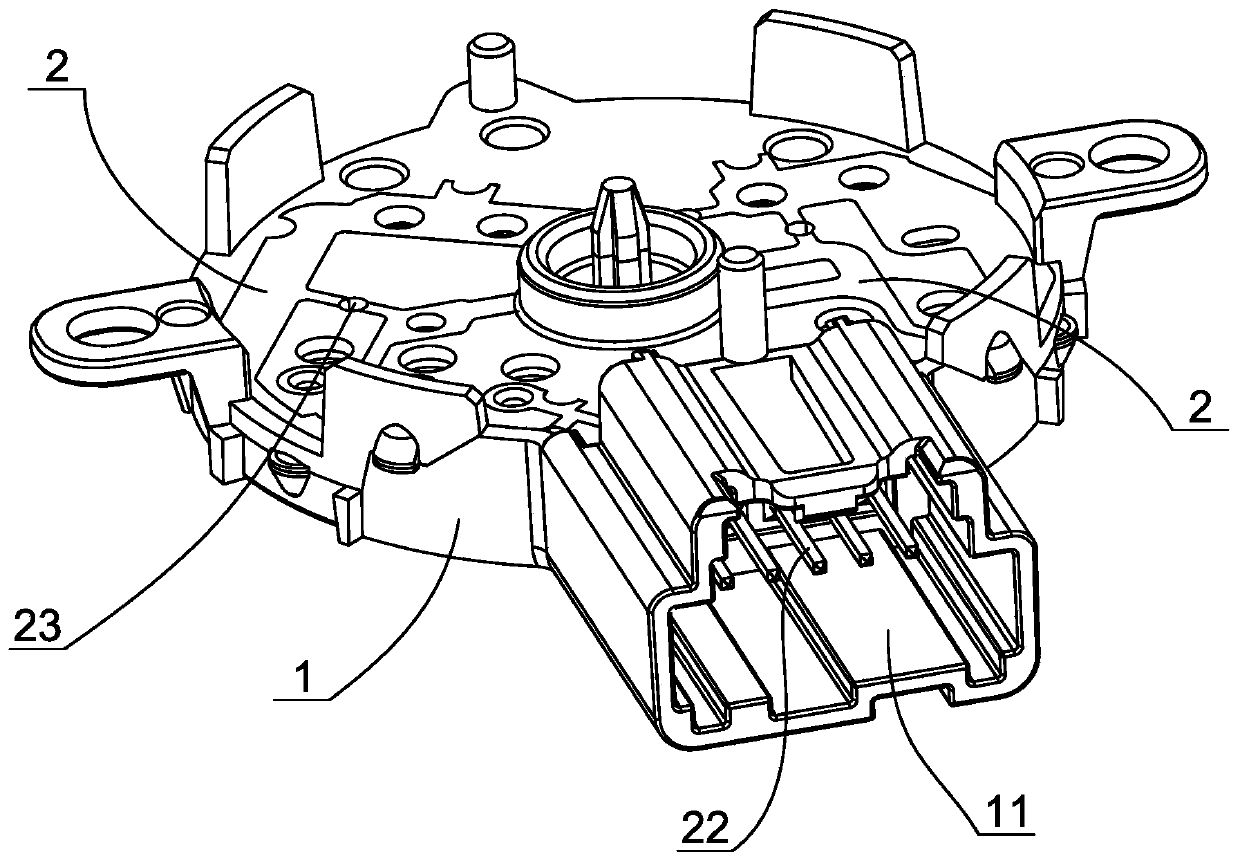

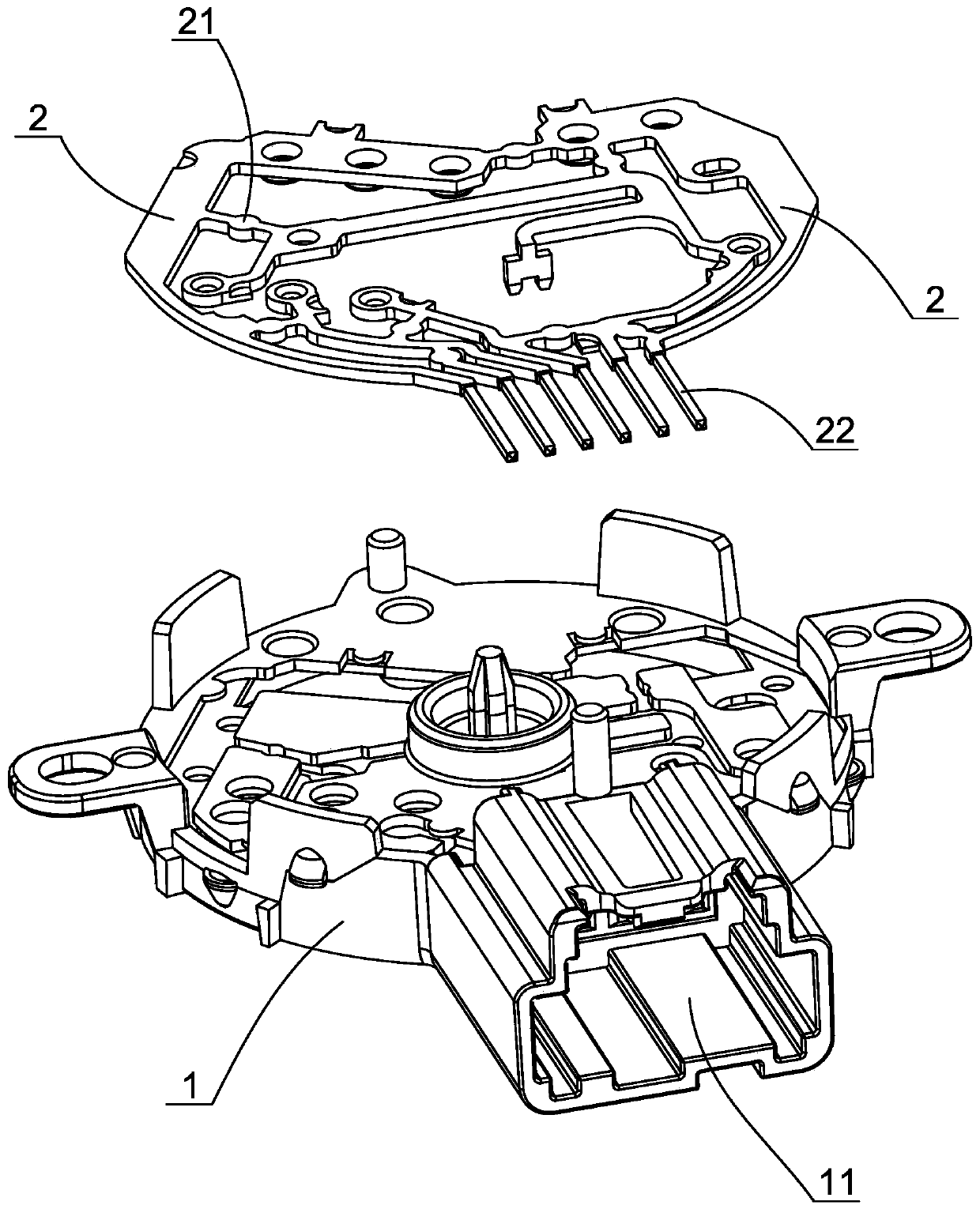

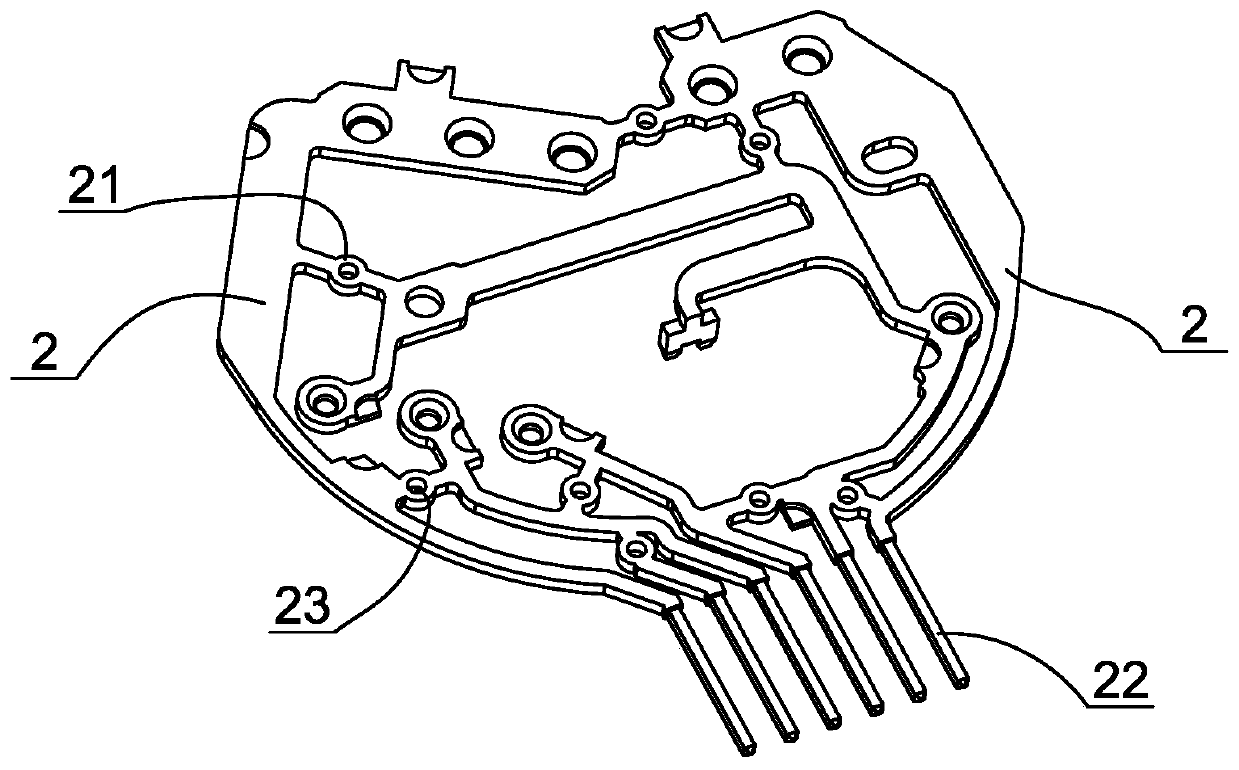

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4As shown, an engine ignition switch includes an injection-molded base 1, six copper return bars 2 embedded in the base, and eight connecting parts 21 integrally arranged between adjacent return bars. , a number of resistors (not shown in the figure), the base has a connection jack 11, each return bar includes a connection terminal 22, and 6 connection terminals are equidistantly located in the connection socket of the base. Welding jacks 23 are arranged on the connecting portion, and the pins of the resistance are inserted in the welding jacks of the corresponding connecting portion and welded together with the connecting portion. The connected return bars are connected radially outside the connecting portion.

[0027] In this way, all the reflow bars are connected to form an integral structure through the connecting portion, and thus can be integrally formed by means of a stamping process or a casting proc...

Embodiment 2

[0030] Embodiment 2: An automatic manufacturing system of an engine ignition switch, which is suitable for automatic production of the engine ignition switch in Embodiment 1. like Figure 5 As shown, it specifically includes a base forming mold (not shown in the figure), an assembly platform 3, and the base forming mold is installed on a corresponding injection molding machine so as to injection mold the base of the engine ignition switch. In addition, a circular punching turntable 4, a punching upper die 5 that can move up and down, a vibrating plate (not shown in the figure) that can automatically sort and transport materials, and a linear vibrating feeder 6 are set on the assembly platform. Two punching lower dies 41 that can be matched with the punching upper die are arranged on the hole turntable, and the two punching lower dies are evenly distributed in the circumferential direction of the punching turntable, wherein the punching lower die located below the punching uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com