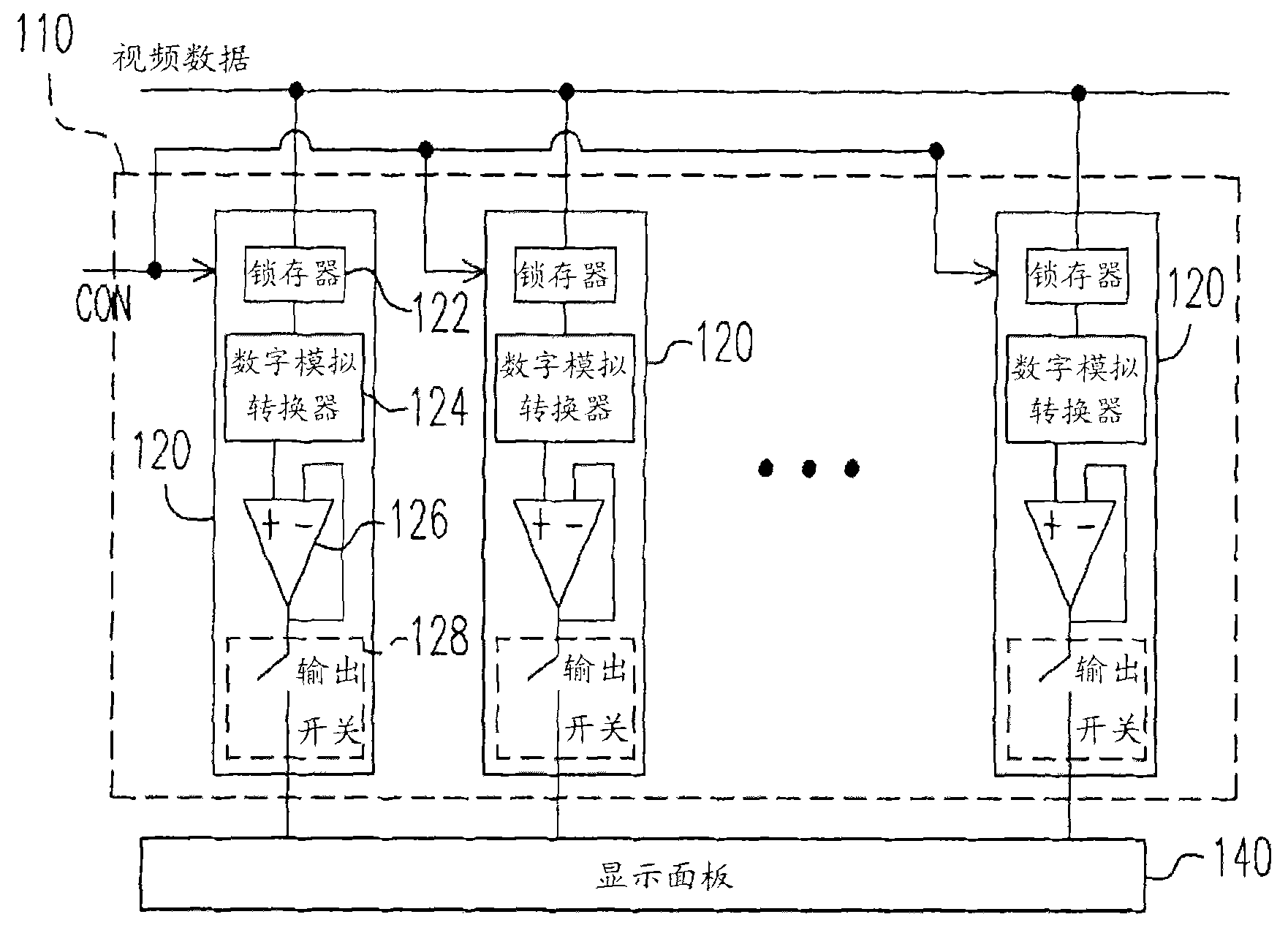

Source electrode driver with low power consumption and driving method thereof

A technology of source driver and driving method, applied in instruments, static indicators, etc., can solve problems such as power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

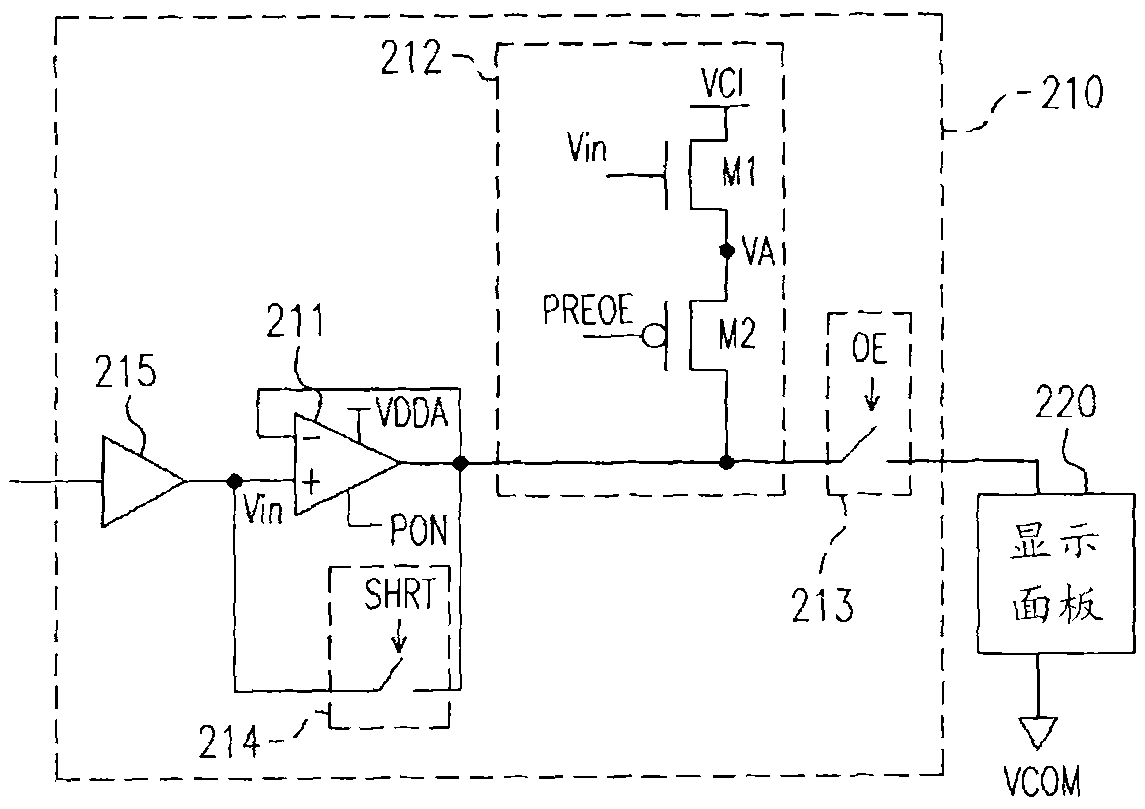

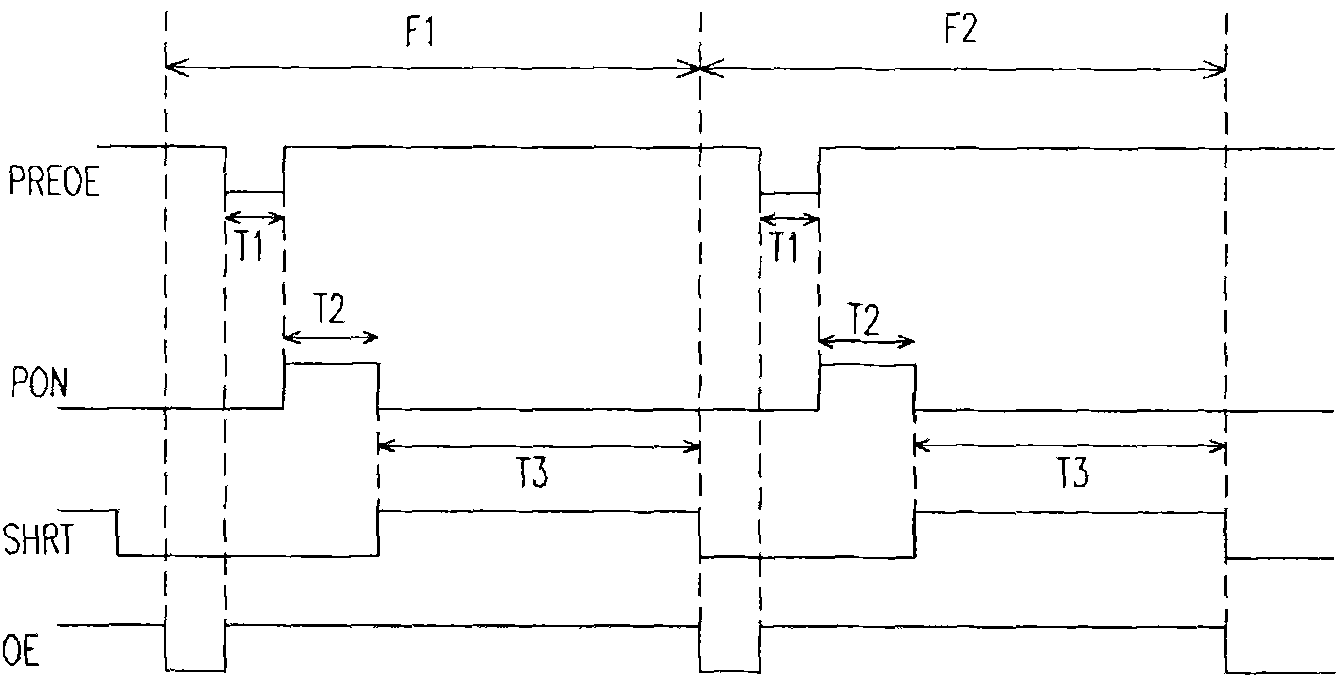

[0036] figure 2 An equivalent circuit diagram of a source driver according to an embodiment of the present invention is shown. Please refer to figure 2 , the source driver 210 of this embodiment is suitable for driving a display panel 220, wherein the display panel 220 may be a liquid crystal display panel or a liquid crystal on silicon (LCoS) panel. In general, the display panel 220 includes a plurality of pixel circuits (not shown), and the liquid crystal alignment corresponding to the position of each pixel circuit can control the light transmittance of the liquid crystal according to the voltage difference between the pixel electrode and the common electrode. , wherein the voltage of the pixel electrode can be changed by using the pixel signal, and the voltage of the common electrode can be a direct current (DC) voltage or an alternating current (AC) voltage. For the convenience of describing this embodiment, a first end and a second end of the display panel 220 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com