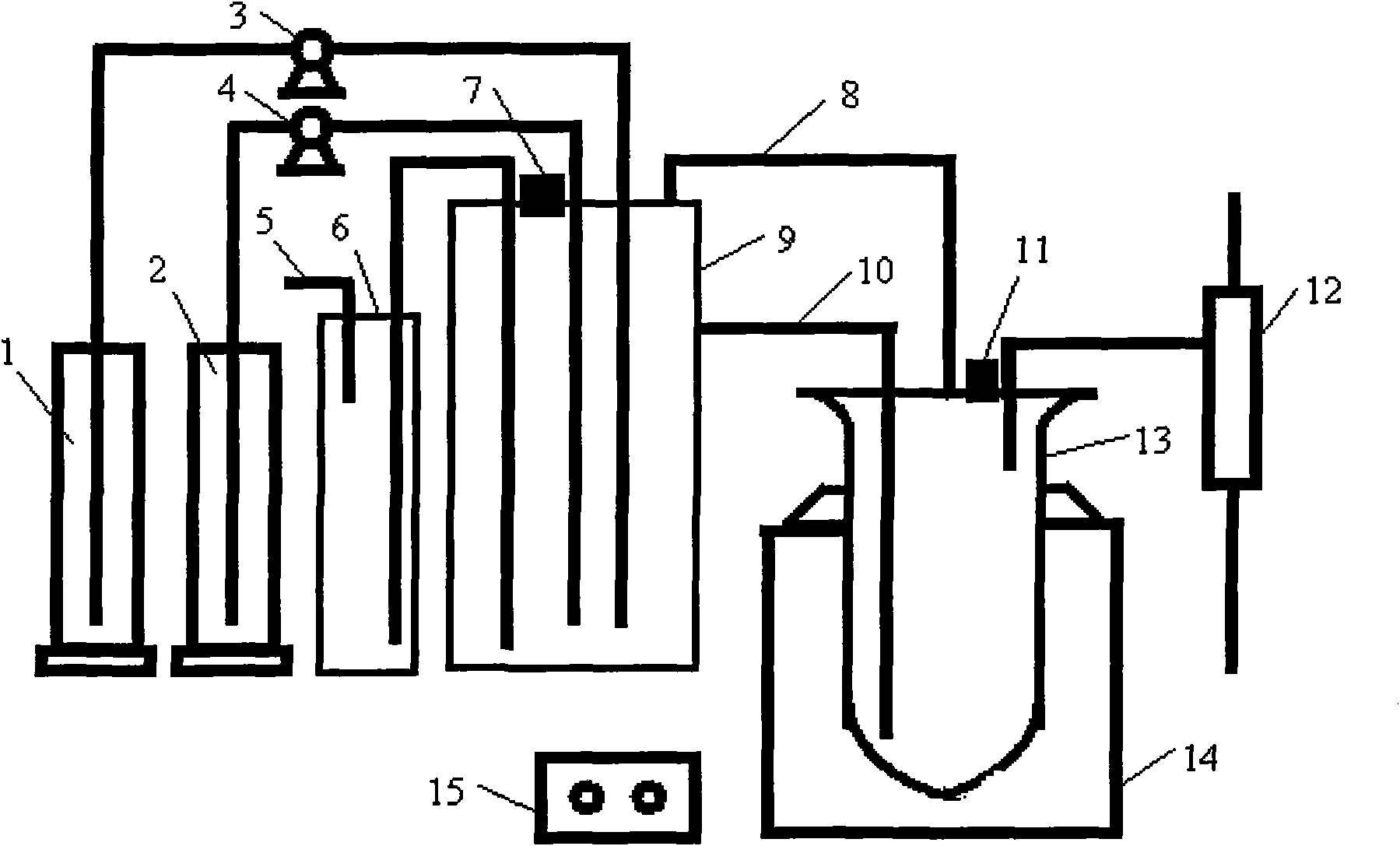

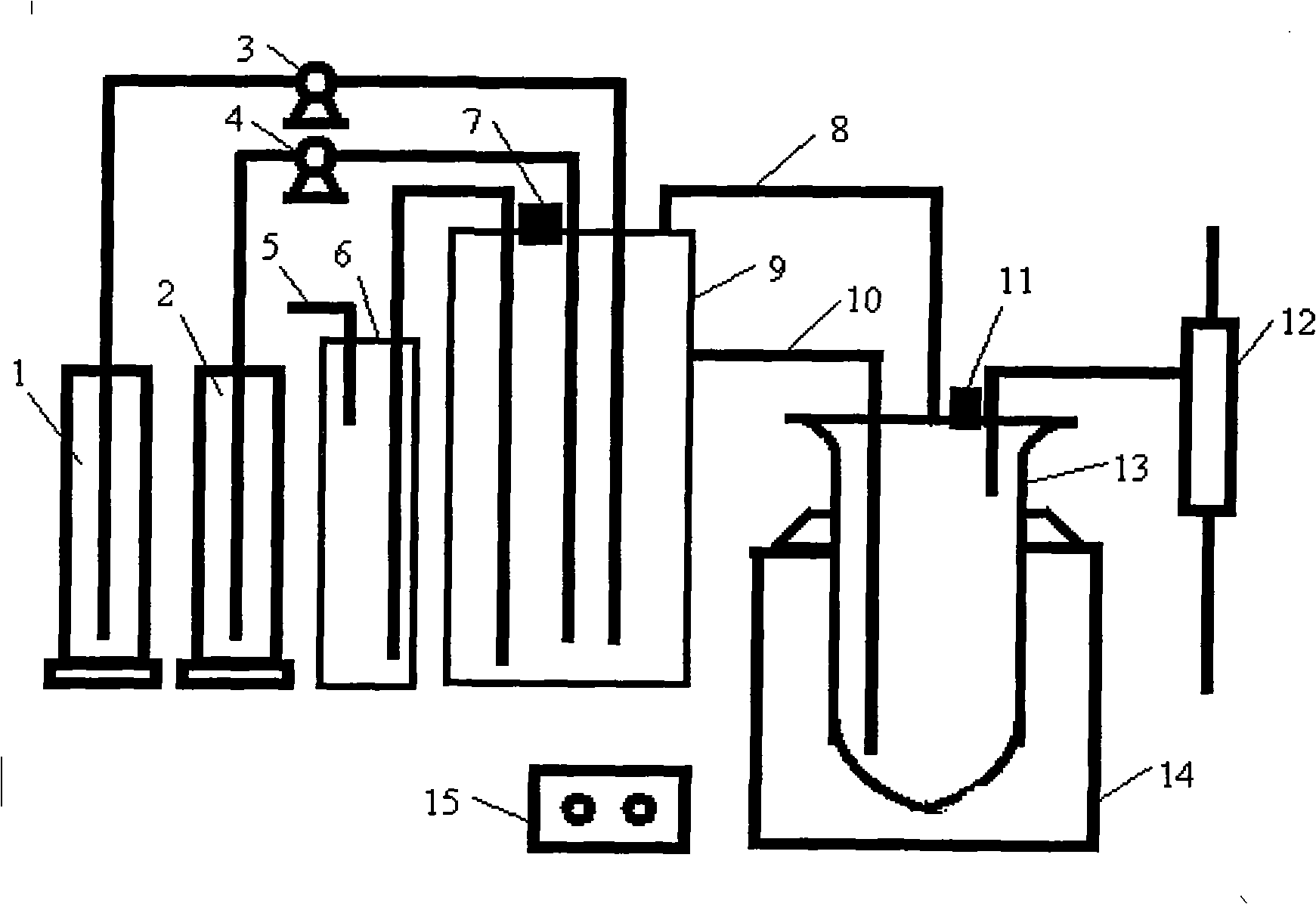

Chlorine dioxide compound disinfectant generator and use method thereof

A chlorine dioxide and disinfectant technology, which is applied in the direction of chlorine oxidation, can solve the problems of reducing the conversion rate of sodium chlorate, lowering the reaction temperature, and low utilization rate of raw materials, and achieves low equipment investment, high reaction temperature, and high raw material utilization rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: 31.01kg / h chlorine dioxide composite disinfectant generator production technology, 33% sodium chlorate aqueous solution, 29% industrial concentrated hydrochloric acid are added to the first with 47.16L / h and 49.20L / h feed rate respectively In the primary reactor 9, the reaction temperature was raised from normal temperature to 75° C. in the secondary reactor. The composite gas of chlorine dioxide and chlorine gas generated in the reactor is mixed with the treated water in the water injector 12 . The output of available chlorine can reach 31.01kg / h, and the conversion rate of sodium chlorate is 89.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com