Pipe pile waste heat recovery system

A technology of waste heat recovery system and pipe pile, which is applied in the direction of steam engine device, steam application, machine/engine, etc. It can solve the problems of low steam recovery efficiency, heat waste of pipe pile, heat waste of condensed water, etc., and achieve good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

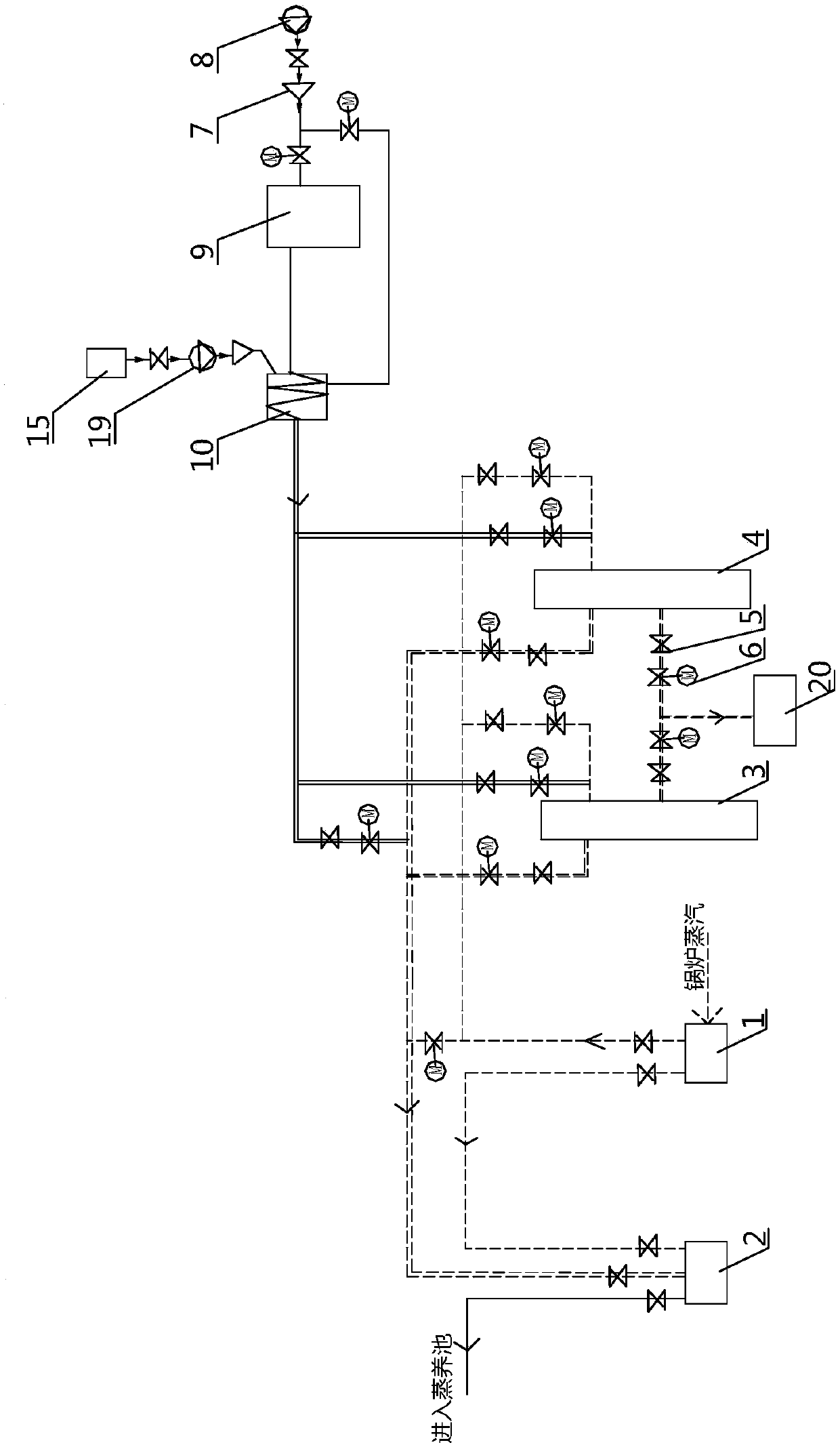

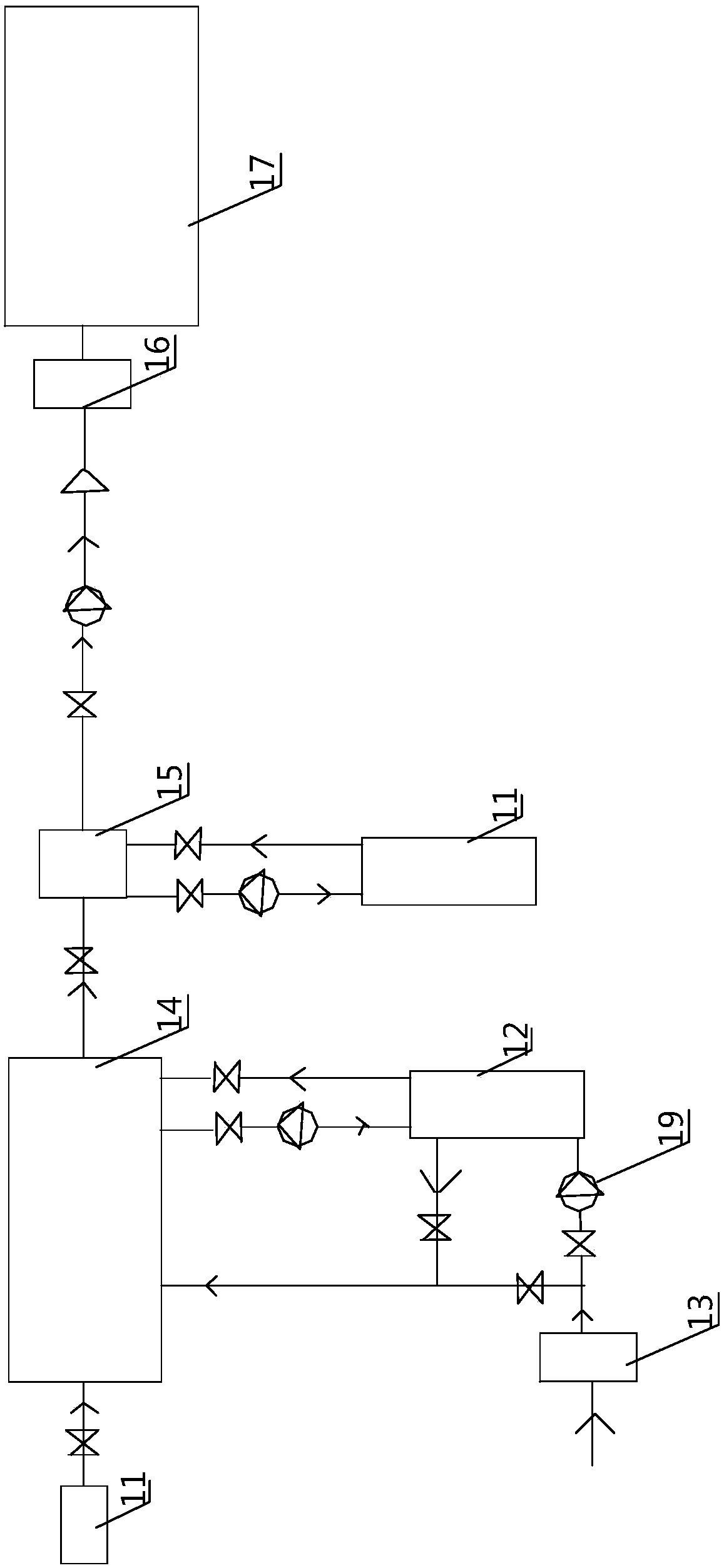

[0038] like Figure 1-5 As shown, in the waste heat recovery system for pipe piles described in Embodiment 1 of the present invention, the purpose of the technical means implemented is to solve the problem of heat waste existing in the production process of pipe piles and to use these waste heat in a reasonable and effective manner. It can be guided and utilized to make it play a role in improving the efficiency of the entire system, and on the basis of solving this technical problem, it can overcome the defect of low steam utilization rate in the original production process and make it help to improve the boiler heating efficiency.

[0039] In order to embody the advantages of the technical means adopted in the present invention, it is now specifically analyzed by comparing with the current pipe pile production process: (in the technical scheme of the present invention, due to all gate valves, check valves, electric valves and other valve components, their respective Therefor...

Embodiment 2

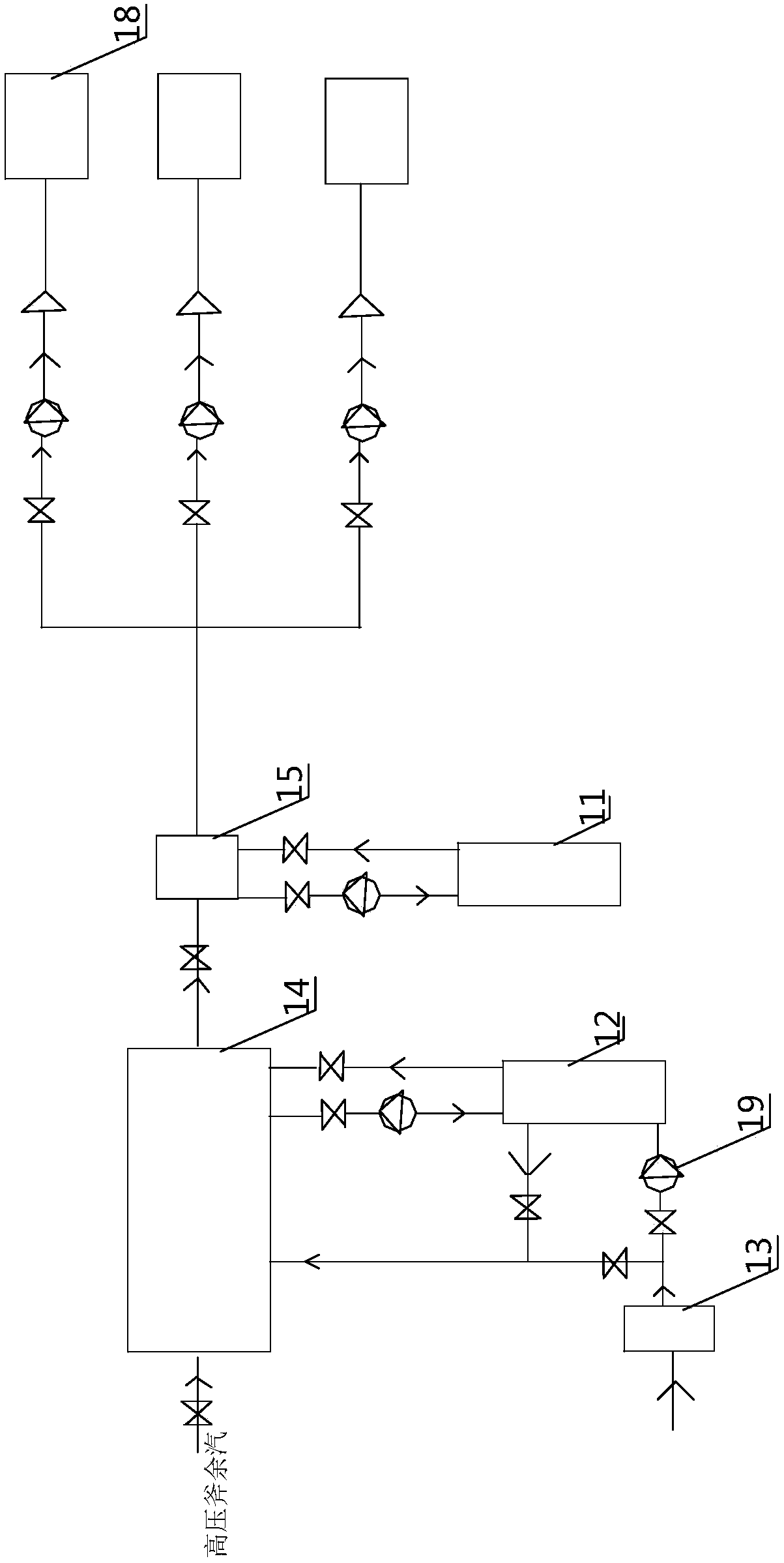

[0056] like image 3 As shown, the pipe pile waste heat recovery system described in Embodiment 2 of the present invention is a further supplement based on the technical means implemented in Embodiment 1. It belongs to the same concept as the technical solution adopted in Embodiment 1 and solves the same problem. The specific implementation content is as follows: the implemented waste steam-water heat exchanger I11 can also be equipped with three steam desuperheating and pressure reducing devices 18, and the hot water stored in the high-temperature water storage tank 15 is used to spray the three The steam desuperheating and pressure reducing device 18 is used to reduce the temperature of the external ultra-high temperature and high pressure steam, and convert the ultra-high temperature and high pressure steam into three kinds of steam of high temperature 180-200°C, medium temperature 130-150°C, and low temperature 110-120°C with a pressure of 10 kg. Low temperature 110-120°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com