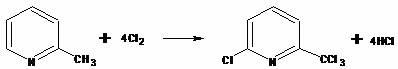

Production method of 6-chloro-2-(trichloromethyl)pyridine

A technology of trichloromethylpyridine and dichloromethylpyridine is applied in the field of nitrogen fertilizer synergist 6-chloro-2-trichloromethylpyridine, which can solve the problems of low product yield, material blockage and the like, and reduce production Cost and production process control are simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 96 kg of 4-chlorobenzotrifluoride into a 300L glass-lined reactor, add 160 kg of 2-methylpyridine and 20 kg of 4-chlorobenzotrifluoride into a high-level metering tank to form a 2-methylpyridine solution. Start stirring, after the reactor is heated to 165°C, feed chlorine at 9kg per hour, keep the reaction temperature at 165°C, add 2-picoline solution at 2.25kg per hour, and react for 8 hours; the reaction temperature is increased to 170°C, Keep warm, increase the amount of chlorine gas per hour to 12kg, increase the amount of 2-picoline solution to 3.375kg / h, and react for 8 hours; increase the reaction temperature to 180°C, keep warm, increase the amount of chlorine gas per hour to 15kg , the amount of 2-picoline solution added is increased to 4.5kg / h, and the reaction is carried out for 8 hours; the reaction temperature is increased to 190°C, kept warm, and the amount of chlorine gas per hour is increased to 27kg, and the amount of 2-picoline solution added is inc...

Embodiment 2

[0036] Add 1820kg of dichlorobenzene into the 3000L glass-lined reactor, add 260kg of 2-picoline and 780kg of dichlorobenzene into the high-level metering tank to make a 2-picoline solution. Start stirring, after the reactor is heated to 135°C, feed chlorine gas at a rate of 50-60 kg per hour, keep the reaction temperature at 135°C, add 2-methylpyridine solution at a rate of 35 kg per hour, and react for 10 hours; chlorine gas and 2-methylpyridine The adding speed of pyridine solution is constant, the reaction temperature is raised to 150°C, and the heat preservation is carried out. After 10 hours of reaction, the reaction temperature is raised to 160°C, heat preservation, and further reaction for 10 hours. When the cumulative addition of 2-picoline solution reaches 1040kg, stop adding For 2-picoline solution, feed chlorine gas at 10-12kg per hour, increase the temperature to 190°C, and react for another 3 hours, then take samples for GC analysis every 1 hour, the content of 6-...

Embodiment 3

[0038] Add 20kg of chlorobenzene into the 300L glass-lined reactor, add 240kg of 2-methylpyridine and 4kg of chlorobenzene into the high-level metering tank to make a 2-methylpyridine solution. Start stirring, after the reactor is heated to 160°C, feed chlorine at 15-20kg per hour and add 2-picoline solution at 2-3kg per hour, keep the reaction temperature at 160°C, react for 6 hours; increase the reaction temperature to 175°C, Keep warm, feed chlorine gas at a speed of 30~40kg / h and add 2-picoline solution at a speed of 4~6kg / h, and react for 12 hours; increase the reaction temperature to 190°C, keep warm, and feed chlorine gas at a speed of 30~50kg / h h and 2-picoline solution were added at a rate of 11-12kg / h and reacted for 15 hours; when the cumulative addition of 2-picoline solution reached 244kg, stop adding 2-picoline solution at a rate of 20-22kg per hour Feed chlorine gas at a temperature of 190°C. After another 2 hours of reaction, take samples for GC analysis ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com