Disc spring loading type hydraulic disc brake

A disc brake and brake technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems of low braking reliability, poor structural rigidity, uneven wear of brake pads, etc., to achieve enhanced Rigidity, long service life, effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

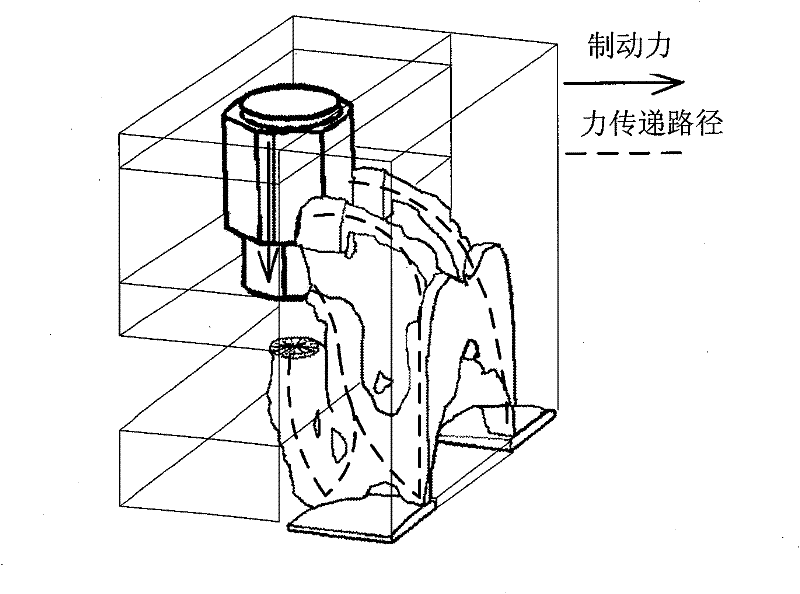

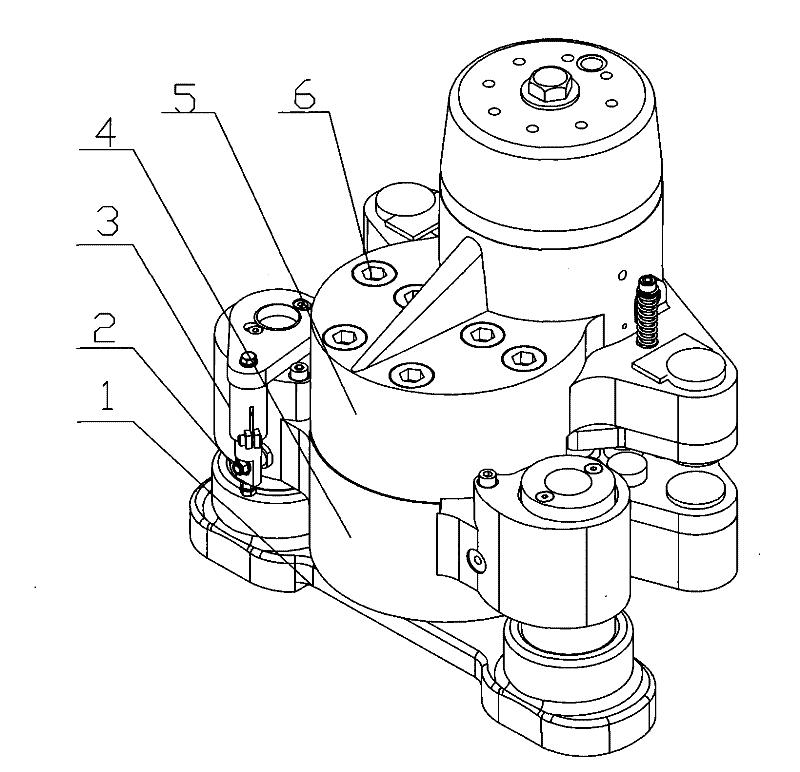

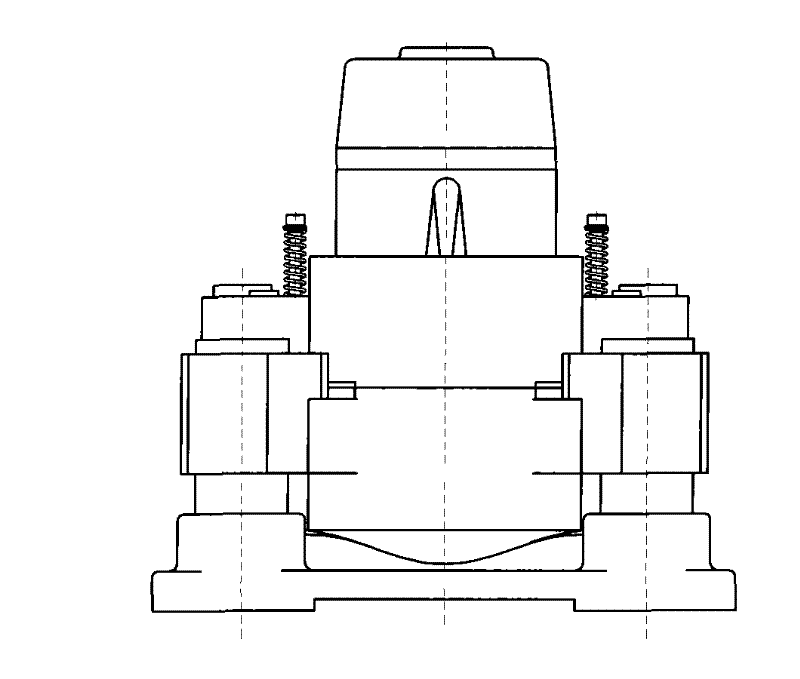

[0029] like Figure 1 to Figure 10 A disc spring loaded hydraulic disc brake shown is an improvement to the existing hydraulic disc brake. The purpose is to apply the finite element structure topology optimization technology, with the minimum volume and maximum structural stiffness as the optimization goal, configure the material density according to the optimal load transfer path, determine the conceptual design frame model, and obtain the optimal structural design scheme. This solution improves the rigidity of the structure, effectively reduces the deformation of the brake body, makes the brake pads evenly loaded, prolongs the service life, and improves the agility, accuracy and reliability of braking. Figure 11 In order to analyze the force transfer model of the brake according to the force of the brake, figure 1 , figure 2 , image 3 Designed for an improved brake shape. from figure 1 , Figure 11 It can be seen from the figure that along the force transmission p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com