Visual full-parameter wheel alignment detection system and method based on linear array images

A line array image, wheel positioning technology, applied in the direction of wheel testing, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

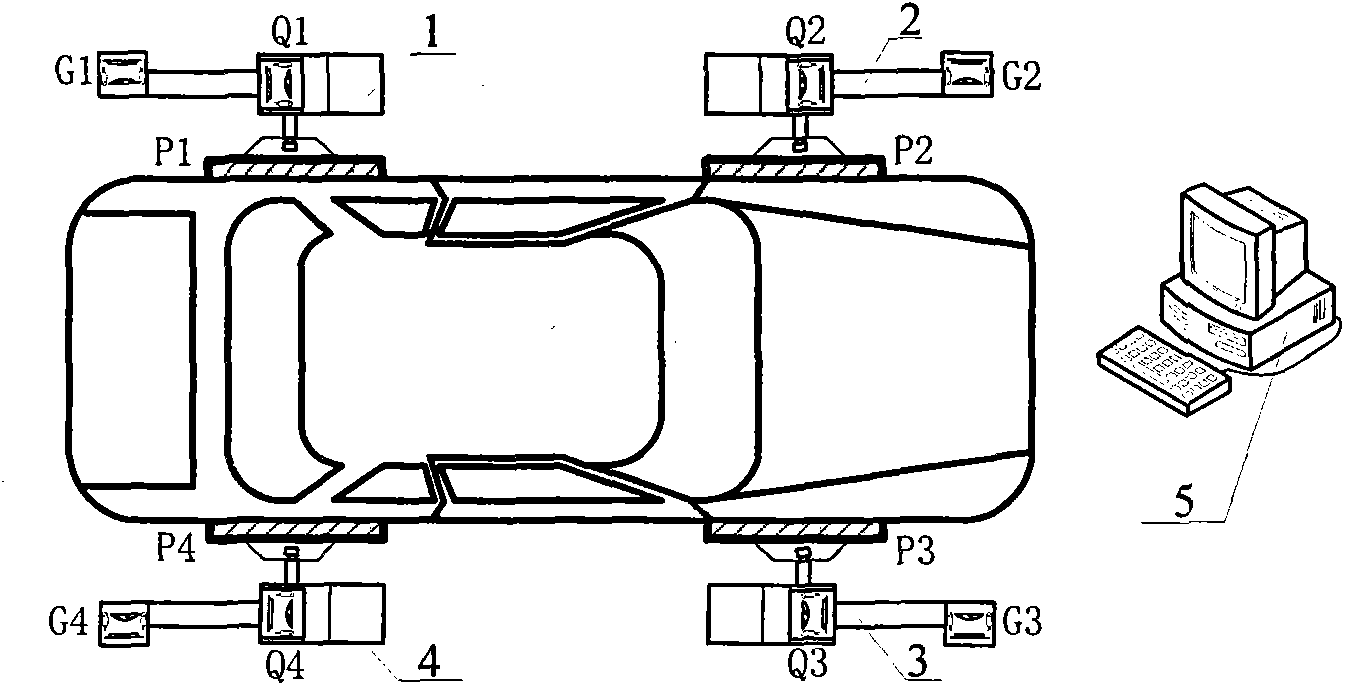

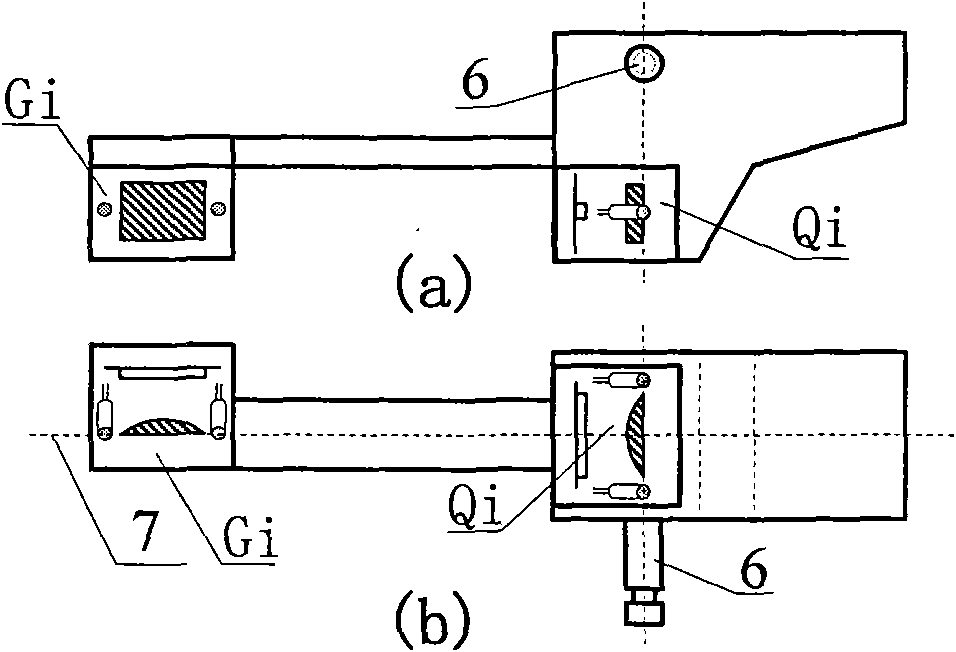

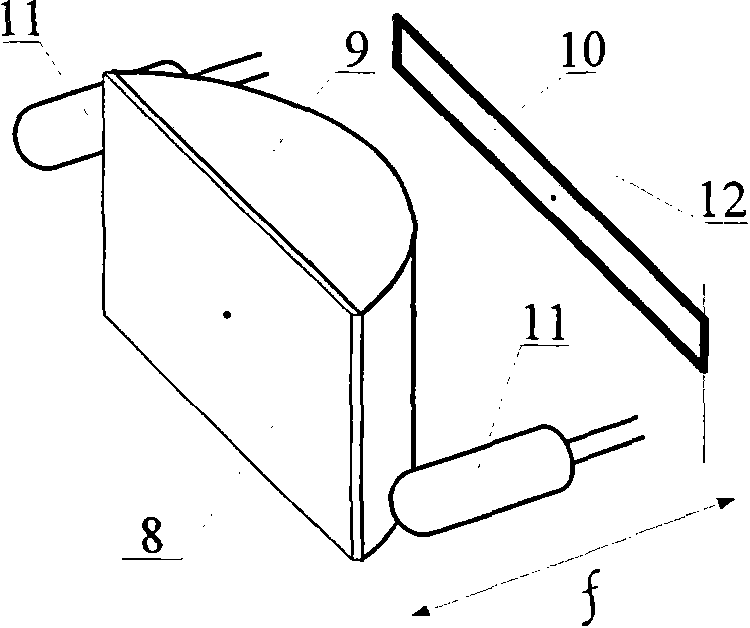

[0038] The visual type full-parameter wheel alignment detection system based on linear array images of the present invention, such as figure 1 As shown, four measuring arms 1-4 and one computer 5 are included. Each measuring arm includes two line array cameras (Qi and Gi, i=1~4) and processing circuits, communication circuits, inclination sensors, power circuits and other components. In this embodiment, the inclination sensor is a MEMS sensor whose model is SCL1700-D11. The internal structure of each line scan camera is the same, such as image 3 As shown, it includes a cylindrical mirror 9 whose axis is in the vertical direction, a filter or an attenuation sheet 8 placed vertically in front of the cylindrical mirror, a line array image sensor 10 placed horizontally at the focal length f behind the cylindrical mirror and its Drive circuit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com