Electrolyte support single-air-chamber solid oxide fuel battery with mutually vertical electrode surfaces

A solid oxide, mutually perpendicular technology, used in solid electrolyte fuel cells, fuel cells, electrical components, etc., can solve problems such as low output performance and large ohmic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

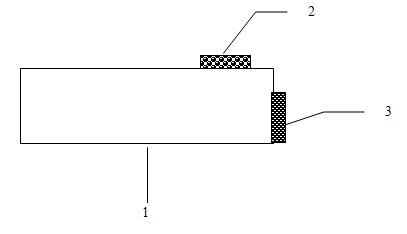

[0008] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. An electrolyte-supported single-gas chamber solid oxide fuel cell with electrode surfaces perpendicular to each other. It consists of an electrolyte support, an anode and a cathode. The anode and cathode are respectively fixed on two surfaces of the electrolyte support that are perpendicular to each other.

[0009] The manufacturing process of the battery in this embodiment is as follows: 1. Put the electrolyte powder into the mold, press it into a square green body under a pressure of 10-2000 MPa, and sinter it at 1300 ° C ~ 1500 ° C for 4 hours to obtain the electrolyte support Body 1; 2. Evenly coat the prepared anode slurry on a plane of the electrolyte support, sinter at 1150°C~1350°C for 2~4h, and then evenly coat the prepared cathode slurry on The other plane of the electrolyte support body perpendicular to the plane where the anode is located is sintered at 1000° C. to 1200° C. for 2 to 4 hours to obtain the bat...

specific Embodiment approach 2

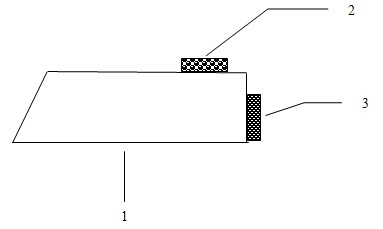

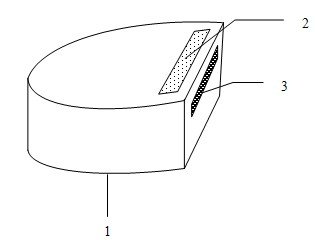

[0011] Embodiment 2. The difference between this embodiment and the electrolyte-supported single-chamber solid oxide fuel cell with electrode surfaces perpendicular to each other described in Embodiment 1 is that the electrolyte support 1 is a cuboid, cylinder or platform.

[0012] The electrolyte support 1 in this embodiment can also be a trapezoidal platform, and the electrode distribution is as follows: figure 2 shown.

[0013] For different electrolyte support 1 conditions, the specific structure of the battery pack has the following forms:

[0014] combine Figure 5 This embodiment is described. In this embodiment, the anode and cathode of the battery are respectively arranged on the two sides of the block-shaped electrolyte support 1 along one edge to form a group of single cells. The cathodes in the former group of single cells are connected to the anodes in the latter group of single cells through high temperature resistant wires 4 to form a series battery pack of 2...

specific Embodiment approach 3

[0019] Specific embodiment three, combine Figure 1~9 Describe this specific embodiment. The difference between this embodiment and the electrolyte-supported single-chamber solid oxide fuel cell whose electrode surfaces are perpendicular to each other described in Embodiment 1 or 2 is that the cross-sectional shapes of the anode 2 and the cathode 3 are square, round or toroidal.

[0020] This embodiment can meet the needs of batteries with different structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com