Multi-motor cluster driving control technology

A drive control and multi-motor technology, which is applied in the direction of controlling the combination of DC and AC motors, can solve the problems of low integration, high hardware cost, and low motor precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

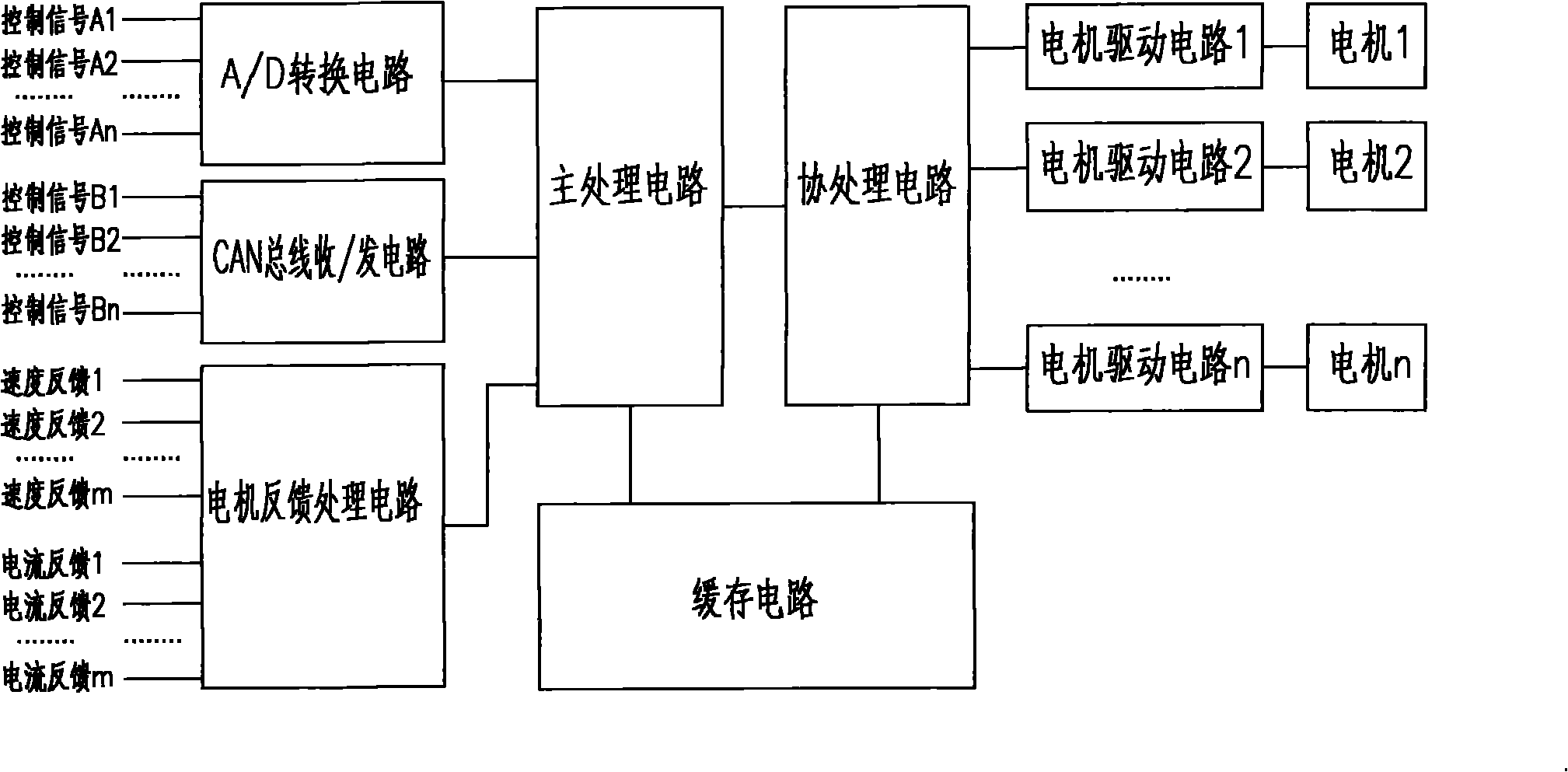

[0014] The main processor chip selects DSP, which receives all motor control commands and all motor feedback signals through related peripheral chips, generates control command words through comprehensive calculation, refreshes the corresponding address of the cache chip, and notifies the coprocessor chip.

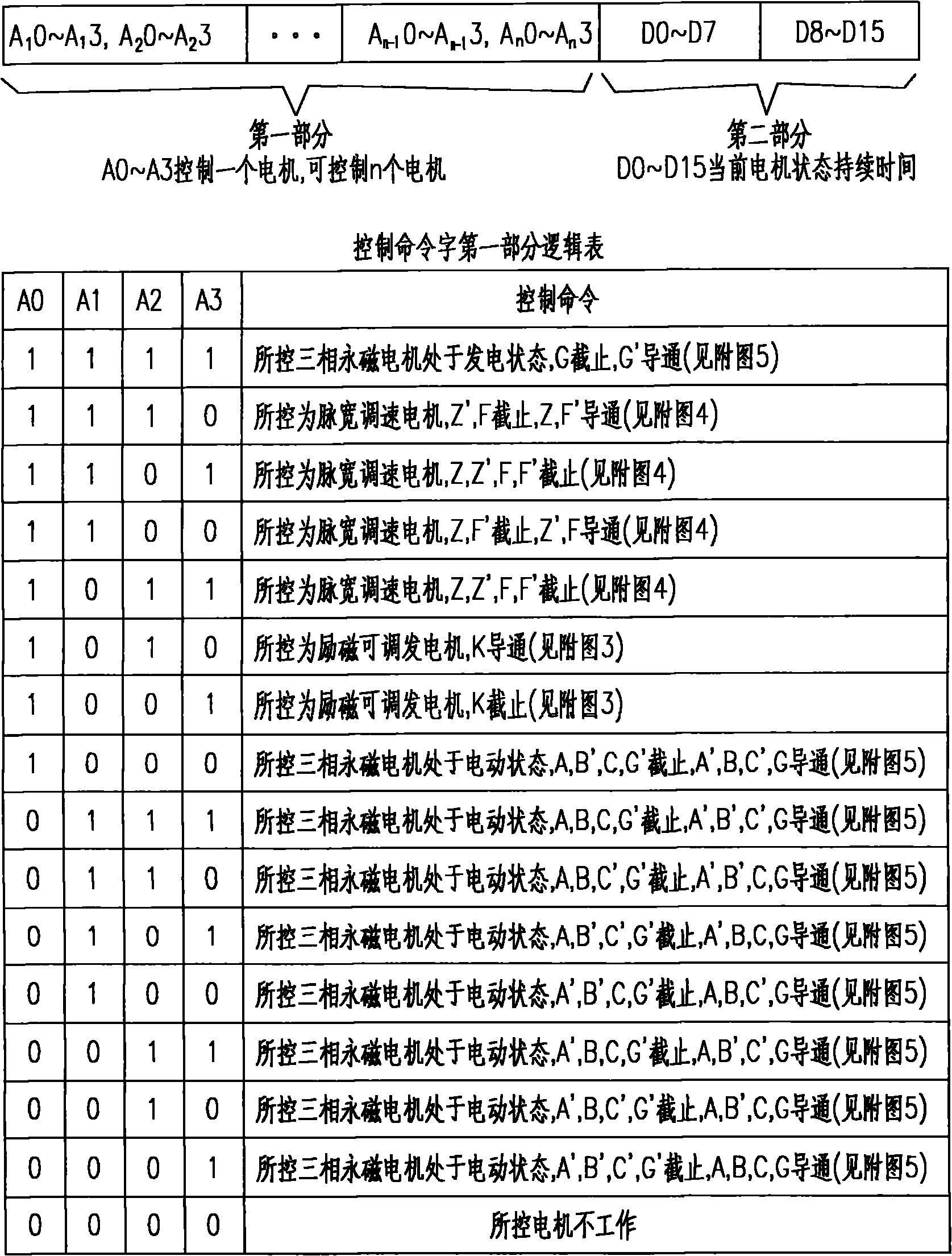

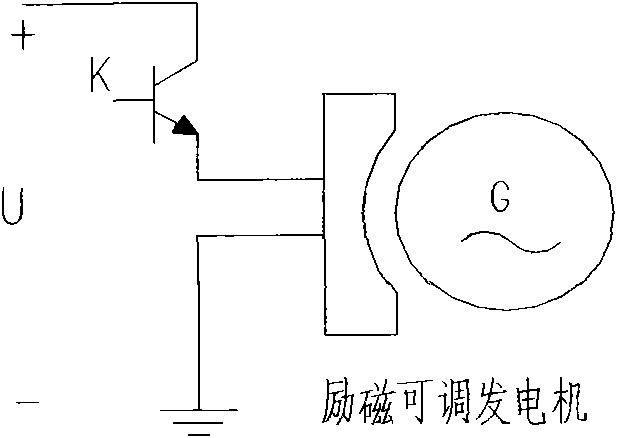

[0015] The control command word is divided into two parts. The number of digits (BIT) in the first part is four times the number of motors. Every four bits (nibbles) correspond to a motor. For example, the first four bits are "0000" to indicate that the control command word Do not control the motor with number 1, "1111" means that the motor with control number 1 is in the power generation state, "1110" means that the pulse width speed regulation of the motor with control number 1 is at high level, "1101" means that the motor with control number 1 is at a high level The pulse width speed regulation of the motor is low level, and the remaining combinations respectively repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com