Process and apparatus for producing fluorinated gaseous compound

A manufacturing method and compound technology, applied in the direction of nitrogen compounds, interhalogen compounds, chemical instruments and methods, etc., can solve the problems of increasing the capacity of the reactor 22, and achieve the effect of less risk of failure and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

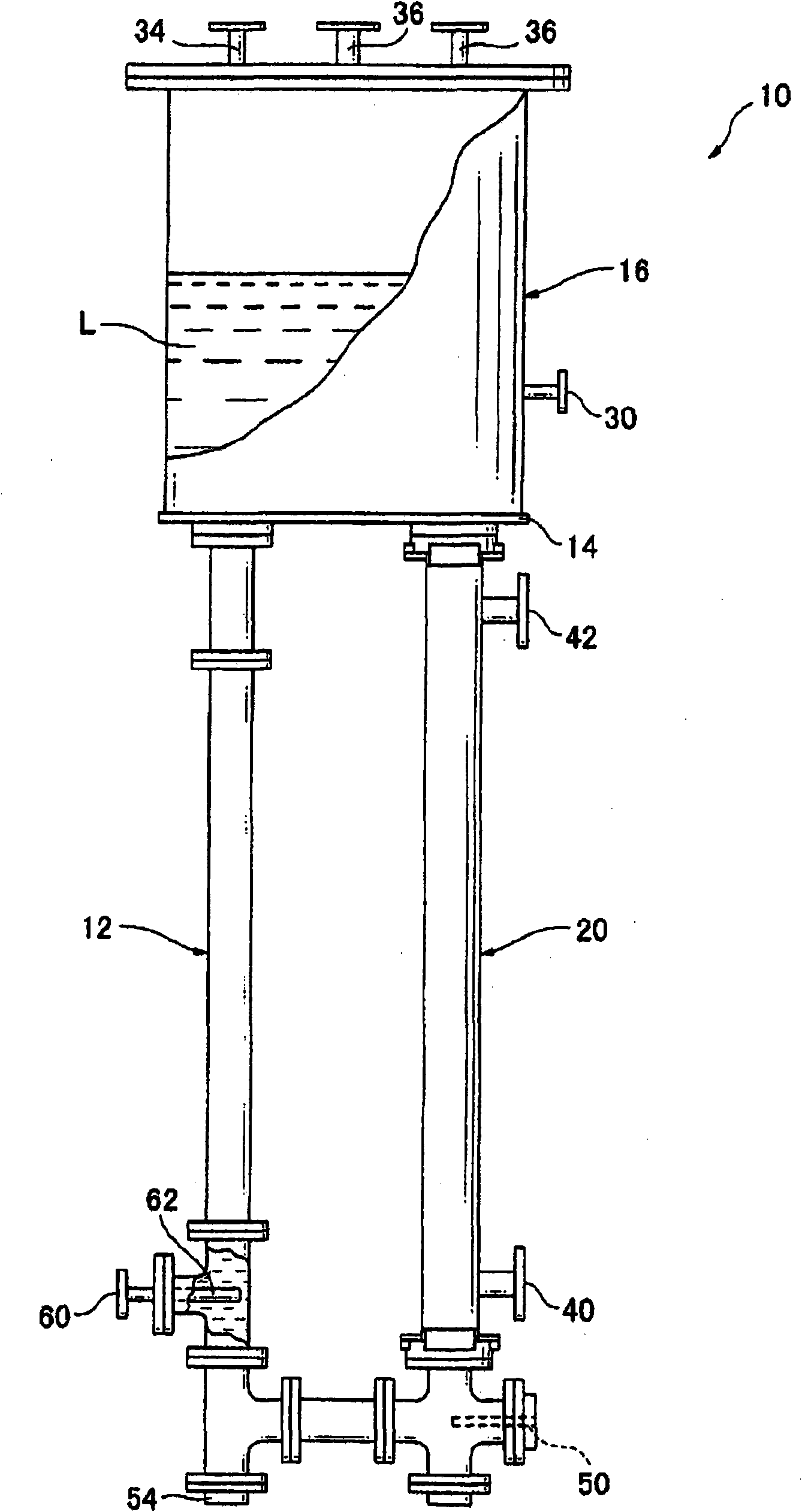

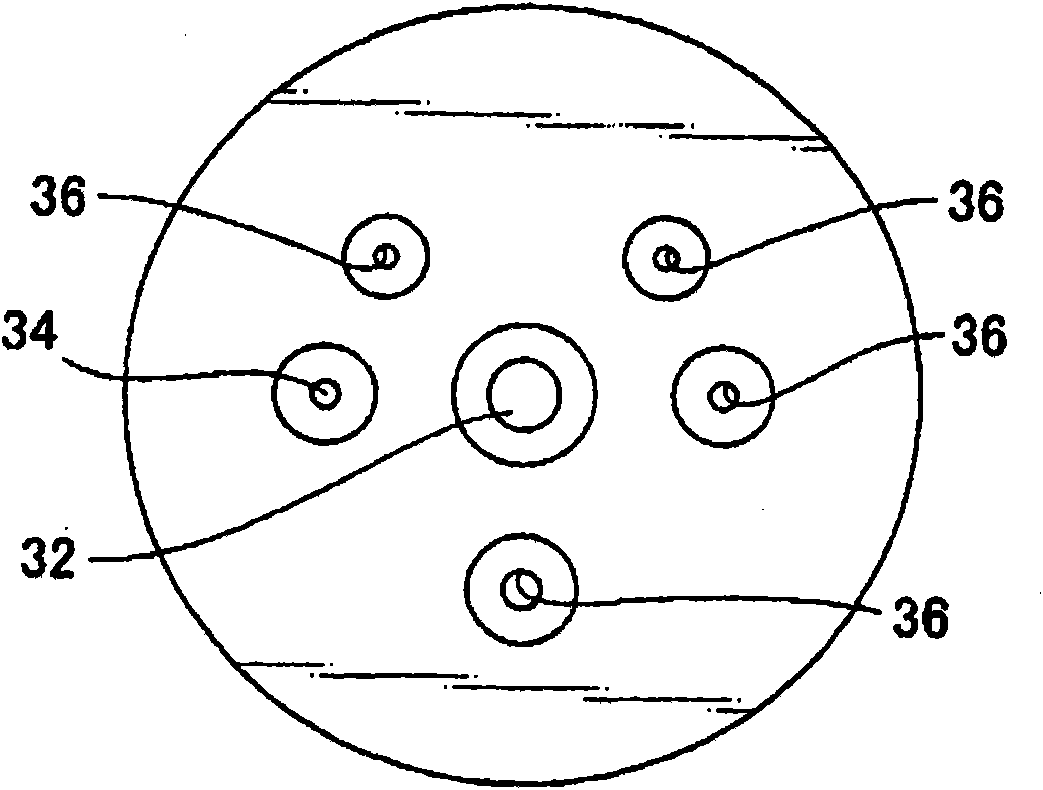

[0064] ready to have figure 1 The structure of the fluorinated gas compound plant 10 is shown as a reaction plant. The raw material liquid L (NH 4F·2.0HF), the raw material liquid L is introduced into the reaction device until the height of the separation layer 16 is roughly in the middle. The amount of the introduced raw material liquid is about 35L. During the reaction, the reduced amount of the raw material liquid L is appropriately replenished from the reaction liquid replenishment port 54 .

[0065] From the raw material supply port 60, the raw material gas CLF is introduced at a flow rate of 4SLM 3 , the reaction is started, and the reaction gas NF obtained by the reaction is taken out from the gas outlet 36 2 Cl, NFCl 2 , a part of which passes through a pipe (made of SUS304) not shown in the figure, and returns to the raw material supply port 60 . The flow rate of the reaction product gas introduced from the raw material supply port 60 is 40 to 60 SLM.

[0066] ...

Embodiment 2

[0069] ready to have figure 1 The structure of the fluorinated gas compound plant 10 is shown as a reaction plant. The raw material liquid L (NH 4 F·2.0HF), the raw material liquid L is introduced into the reaction device until the height of the separation layer 16 is roughly in the middle. The amount of the introduced raw material liquid is about 35L. During the reaction, the reduced amount of the raw material liquid L is appropriately replenished from the reaction liquid replenishment port 54 .

[0070] From the raw material supply port 60, introduce raw material gas ClF at a flow rate of 0.4SLM 3 , the reaction is started, and the reaction gas NF obtained by the reaction is taken out from the gas outlet 36 2 Cl, NFCl 2 , so that its entire amount passes through the subsequent reaction to form "the gaseous compound NF obtained by further fluorination 3 ”, let a part of the obtained gas compound pass through a pipe (made of SUS304) not shown in the figure, and return to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com