Supported liquid membrane lithium extraction device and membrane process brine lithium extraction process

A technology for supporting liquid membranes and supporting membranes, applied in the direction of improving process efficiency, etc., can solve problems such as large amount of evaporated water, easily corroded equipment, and damage to the adsorption capacity of adsorbents, and achieve high separation efficiency, low consumption, and simple devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

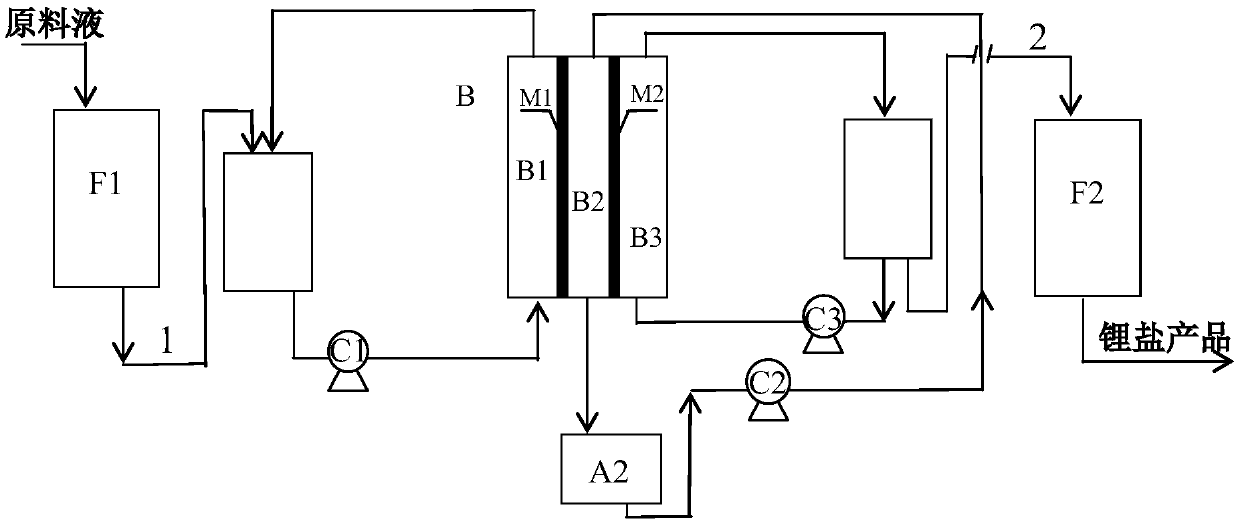

[0025] Such as figure 1 As shown: the supported liquid film lithium extraction device consists of lithium extraction liquid tank A1, organic solvent liquid tank A2, stripping agent liquid tank A3, "sandwich" membrane module B, first metering pump C1, second metering pump C2, third The metering pump C3 and related pipelines are connected in a specific order; among them, the "sandwich" membrane module B is divided into three chambers by two support membranes, the hydrophilic support membrane M1 and the hydrophobic support membrane M2, respectively, and the hydrophilic support membrane The front of the support membrane M1 is opposite to the lithium liquid chamber B1, the reverse side of the two support membranes is the extractant chamber B2, and the front of the hydrophobic support membrane M2 is opposite to the stripping agent extraction chamber B3. The bottom of the lithium extraction tank A1 flows through the pipeline through the first metering pump C1 and is connected to the ...

Embodiment 2

[0028]A raw material liquid brine containing 100mg / L of lithium is subjected to lithium extraction treatment using the device and process of the present invention. The brine enters the pretreatment chamber F1, and first settles for 12 hours to remove solid impurities; after settling, the brine supernatant enters the ceramic ultrafiltration section, using alumina ceramic membranes, the membrane pore size is 5nm, and the operating pressure is 0.1MPa; the ultrafiltration permeate enters the vacuum membrane The distillation section uses a hydrophobic alumina ceramic membrane with a pore size of 0.1 μm, a membrane surface flow rate of 1m / s, a vacuum degree of 5KPa on the permeation side, and an operating temperature of 50°C. The concentrated liquid obtained through vacuum membrane distillation is concentrated lithium liquid 1 , the concentration of lithium ions is concentrated to 0.5g / L; 5L concentrated lithium solution 1 enters the lithium extraction solution tank A1, and the brine...

Embodiment 3

[0030] A raw material liquid brine containing 200mg / L of lithium is subjected to lithium extraction treatment using the device and process of the present invention. The brine enters the pretreatment chamber F1, and first settles for 12 hours to remove solid impurities; after settling, the brine supernatant enters the ceramic ultrafiltration section, using a zirconia ceramic membrane with a pore size of 50nm and an operating pressure of 0.3MPa; the ultrafiltration permeate enters the vacuum membrane The distillation section adopts a hydrophobic zirconia ceramic membrane with a membrane pore size of 0.2 μm, a membrane surface flow rate of 2 m / s, a vacuum degree of 10 KPa on the permeation side, and an operating temperature of 60 ° C. The concentrated liquid obtained through vacuum membrane distillation is concentrated lithium liquid 1 , the lithium ion concentration is concentrated to 5g / L; 4L concentrated lithium solution 1 enters the lithium extraction solution tank A1, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com