Anti-whirl method

A technology of anti-rotation and production methods, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0021] refer to figure 1 ,and figure 2 , in the anti-swirl method of the present invention, the preparation method of the anti-swirl device is as follows:

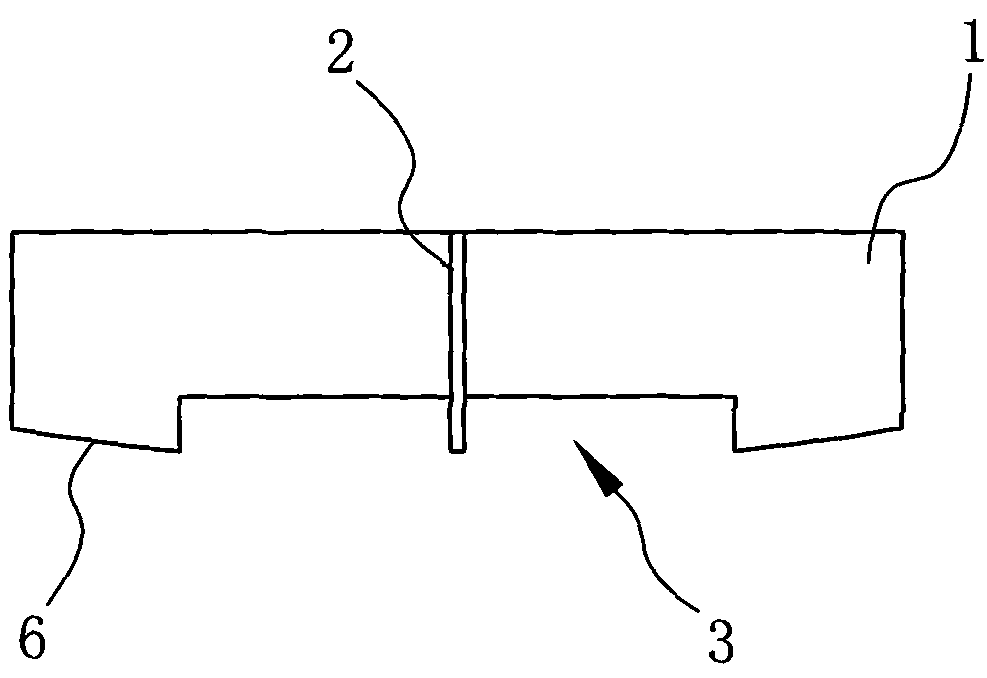

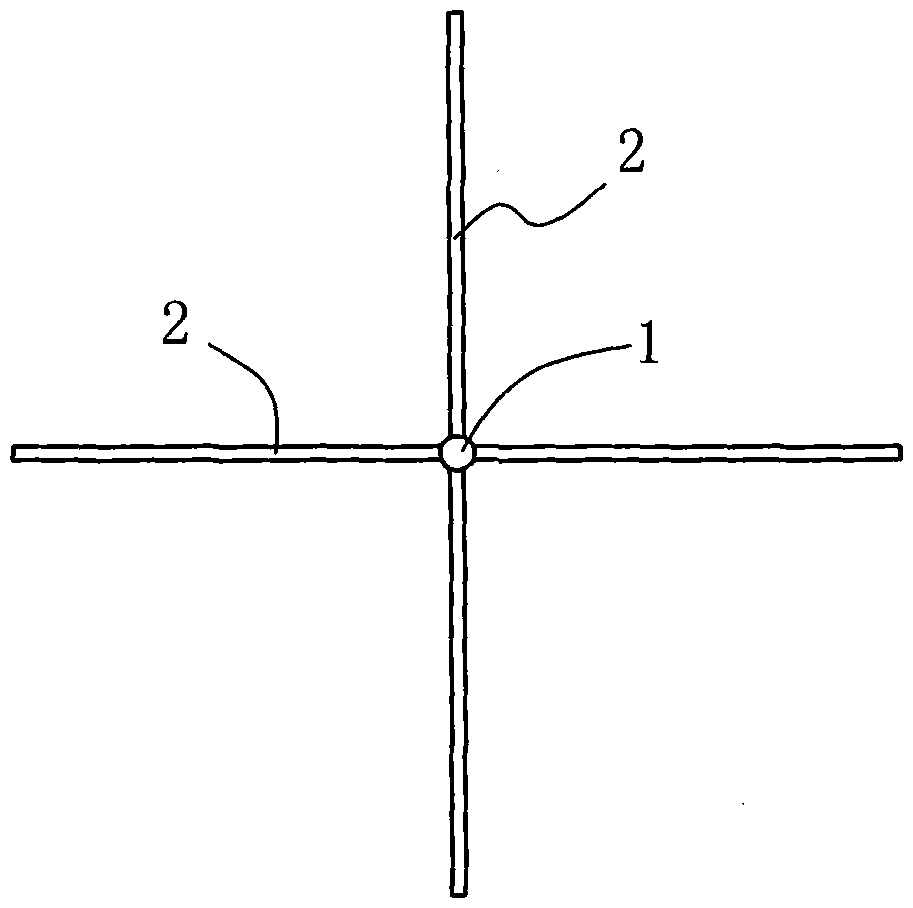

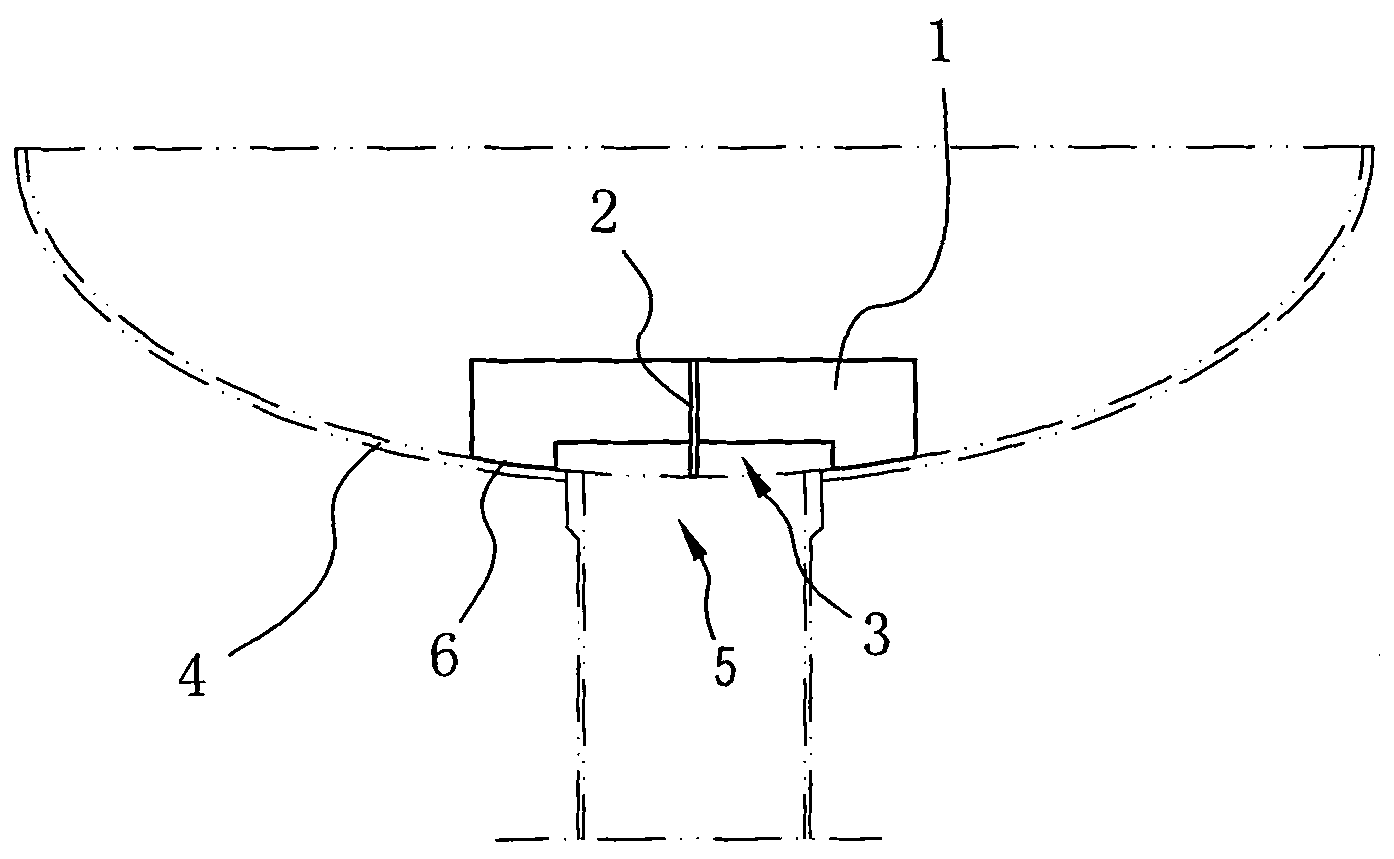

[0022] Each baffle plate 1 is radially fixedly connected to the vertical shaft 2, the anti-swirl flow device is fixedly arranged at the outlet 5 of the reactor 4, and a middle gap 3 is set at the end of the baffle plate 1 near the outlet 5, and the middle The baffles on both sides of the notch 3 are near the kettle end 6 , so that the near kettle end 6 matches the shape of the inner wall of the reactor 4 .

[0023] The near kettle end of many block baffle plates 1 is made into the arc shape that matches with react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com