Strong and tough nylon composite material for high-speed rail sleeper firmware and preparation method thereof

A composite material, tough nylon technology, applied in the formulation of high-strength engineering plastics and its production, can solve the problems of heavy weight, high energy consumption, non-insulation, etc., and achieve the effects of easy molding, excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

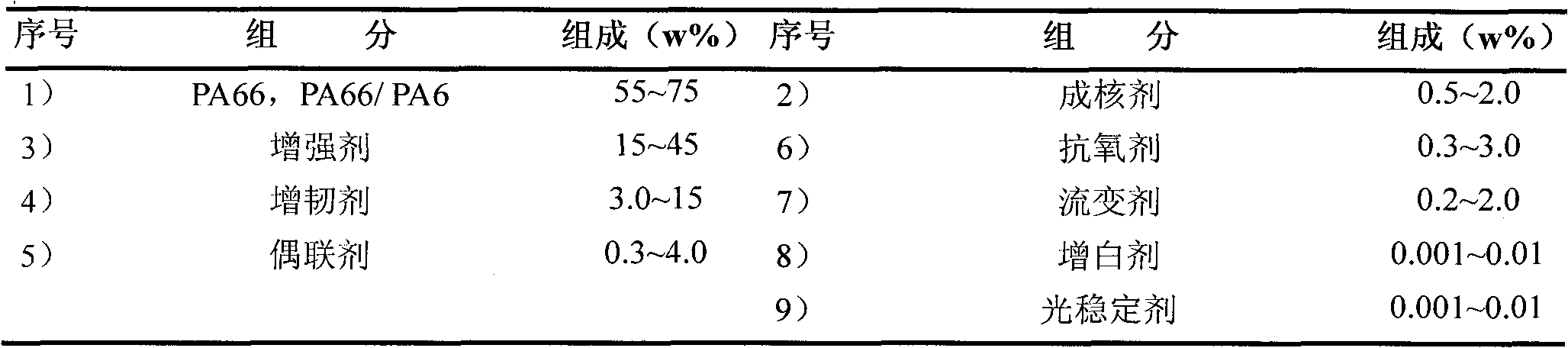

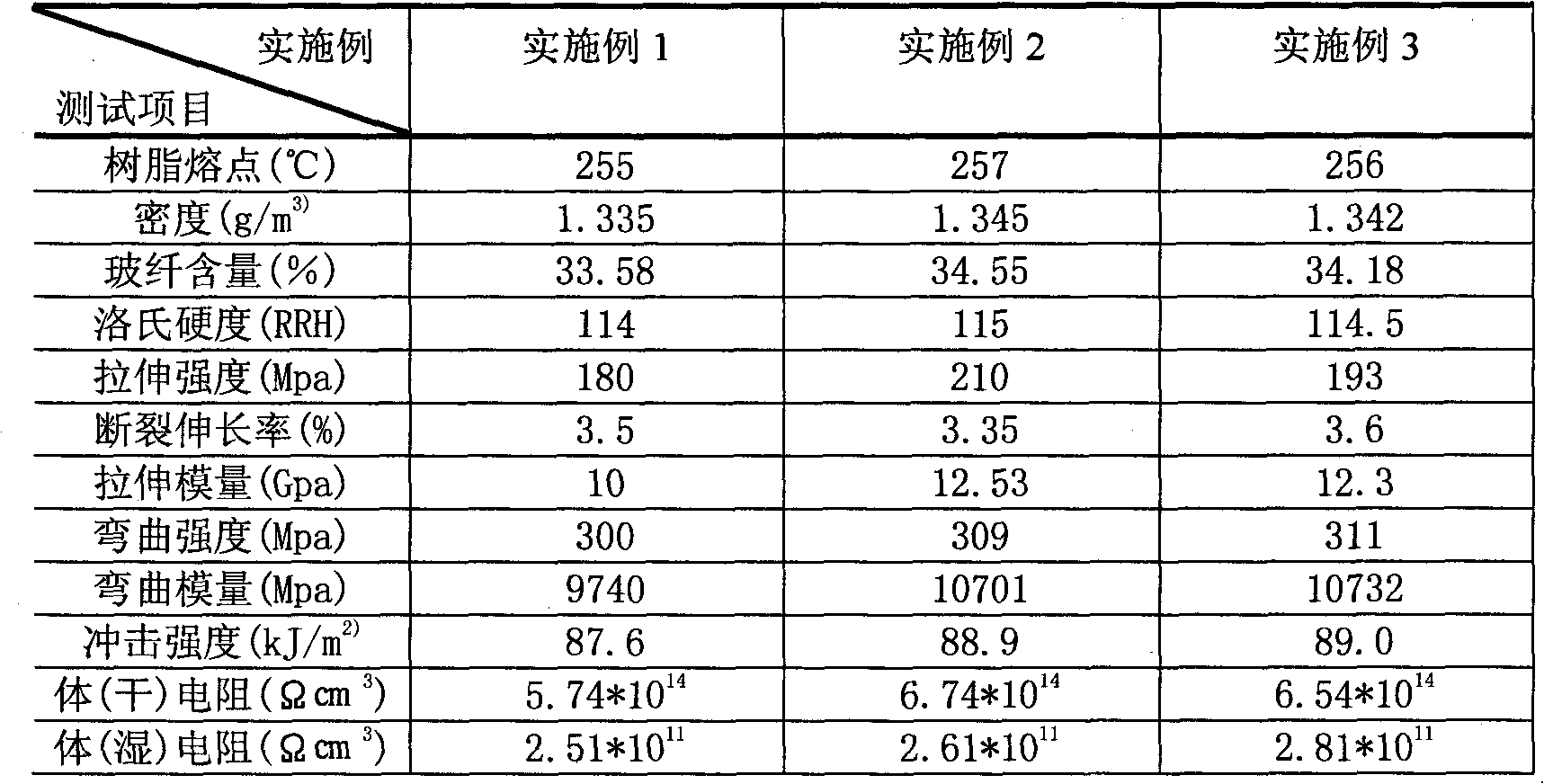

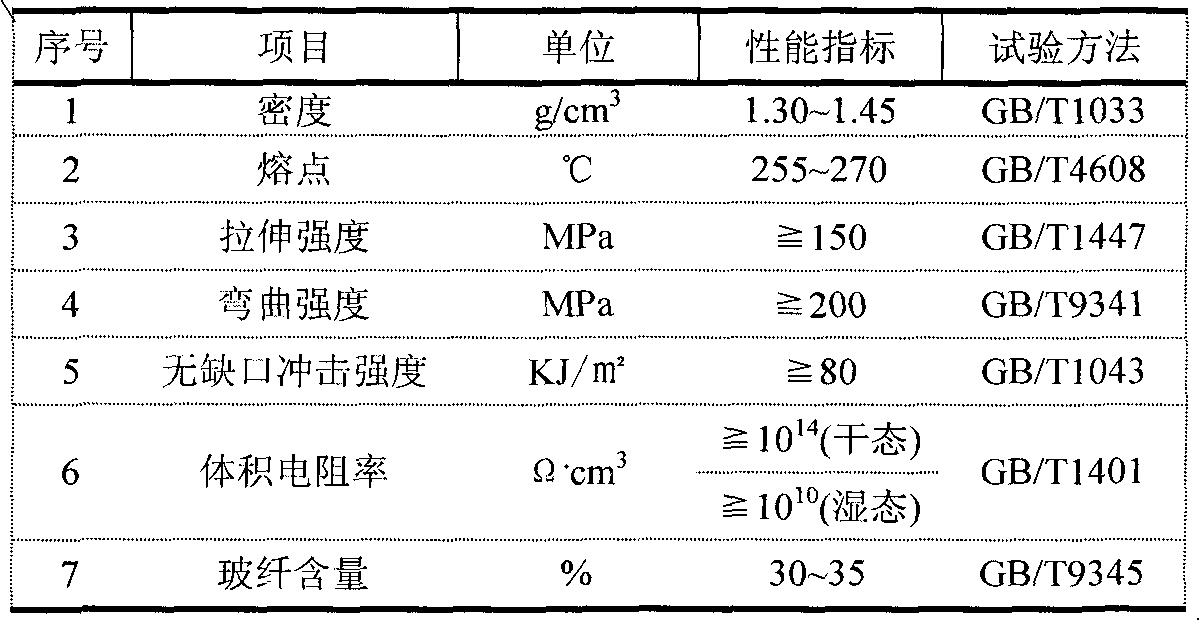

[0028] According to a kind of strong and tough nylon composite engineering material with a weight of 45kg for high-speed rail sleeper, its components and composition (weight %) are calculated, and the component weight is taken:

[0029] A kind of strong, tough nylon composite material and preparation method thereof, its feature comprises the following steps:

[0030] Step 1: Mixing materials: This step is characterized by the following steps, including the following operations:

[0031] Operation 1: Weighing

[0032] 1. Weigh the liquid components in the formula: component 5) coupling agent 200ml for later use.

[0033] 2. Weighing materials: 1) 25 kg of nylon 66 EPR32 resin and 4) 5 kg of toughening agent (EPDM-g-MAH) for later use.

[0034] 3. Weigh the additive components: 2) nucleating agent, 6) antioxidant, 7) rheological agent, 8) whitening agent and 9) light stabilizer totaling 1.0 kg.

[0035] 4. Material preparation: Component 3) Reinforcing agent—alkali-free untwi...

Embodiment 2

[0041] According to a kind of strong, tough nylon composite engineering material that the high-speed rail sleeper firmness of 90kg is used, its component and composition (weight %) are calculated, and take component weight:

[0042] A kind of strong, tough nylon composite material and preparation method thereof, its feature comprises the following steps:

[0043] Step 1: Mixing materials: This step is characterized by the following steps, including the following operations:

[0044] Operation 1: Weighing

[0045] 1. Weigh the liquid components in the formula: component 5) coupling agent 400ml for later use.

[0046] 2. Weighing materials: component 1) 50 kg of nylon 66EPR27 resin, 8 kg of PA6 resin and component 4) 3 kg of toughening agent (POE-g-MAH) for use.

[0047] 3. Weigh the additive components: 2) nucleating agent, 6) antioxidant, 7) rheological agent, 8) whitening agent and 9) light stabilizer total - 2.8 kg.

[0048] 4. Material preparation: Component 3) Reinforci...

Embodiment 3

[0054] According to a kind of strong and tough nylon composite engineering material with a weight of 90kg, its component (weight) and composition (weight %) are calculated, and the component (weight) is weighed:

[0055] A kind of strong, tough nylon composite material and preparation method thereof, its feature comprises the following steps:

[0056] Step 1: Mixing materials;

[0057] This step is characterized by the following steps, including the following operations:

[0058] Operation 1: Weighing

[0059] 1. Weigh the liquid components in the formula: component 5) coupling agent 400ml for later use.

[0060] 2. Weighing materials: 1) 50 kg of nylon 66ST27 resin and 10 kg of PA6 resin for spare use.

[0061] 3. Weigh the additive components: 2) nucleating agent, 6) antioxidant, 7) rheological agent, 8) whitening agent and 9) light stabilizer totaling 2.8 kg.

[0062] 4. Material preparation: Component 3) Strengthening agent - alkali-free untwisted filament spare fish e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com